A3 Mk1

|

Testing ignition system

Testing Hall sender -G163

|

|

|

|

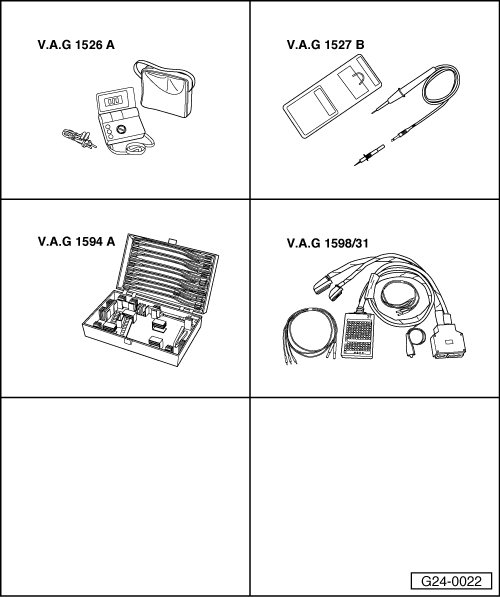

Special tools and workshop equipment required

Fitting location => Fitting locations overview, Page 24-5 The Hall sender indicates the ignition position for Cylinder 1. If the Hall sender fails to function, the knock control is switched off and the ignition timing is retarded slightly because the signals can no longer be assigned to the cylinders. Even without a signal from the Hall sender the engine will continue to run and can also be re-started.

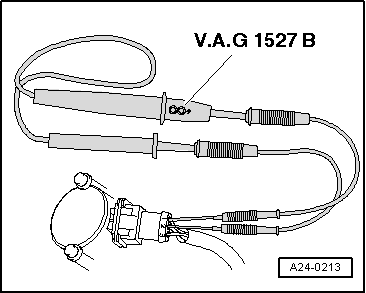

Checking activation

|

|

|

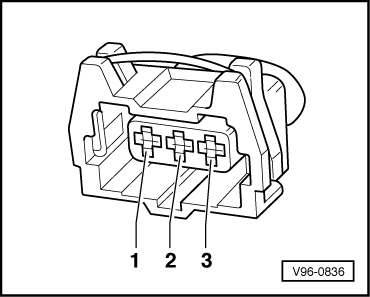

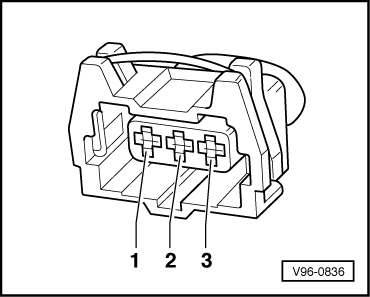

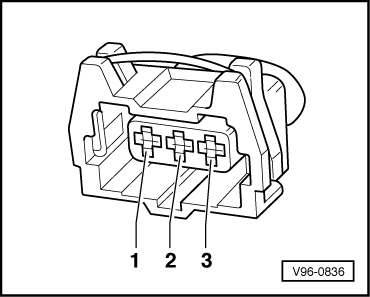

Note: The connector contacts are numbered on the back of the connector.

Note: The LEDs on voltage testers with a low current draw continue to glow faintly between impulses from the engine control unit (rather than going out completely) and become much brighter when receiving an impulse. If the LED does not flash: Checking voltage supply

|

|

||||||||

Testing signal wire

Testing earth wire |

|

||||

If all the readouts match the specifications but the LED does not flash (measurement taken between contacts 1 and 2 without unplugging connector and while operating starter):

If the specifications are not obtained: Testing wiring between Hall sender and engine control unit

|

|

|||||||||

|