-

‒ Check readouts for lambda control in display zones 1 and 2.

|

|

|---|

|

|

Display zones

|

|

|

1

|

2

|

3

|

4

|

|

Display Group 033: Lambda control

|

|

Display

|

xx.x %

|

x.xxx V

|

|

|

|

Indicates

|

Lambda control

Bank 1

|

Lambda probe voltage Bank 1

|

|

|

|

Range

|

-25.0...25.0 %

|

0.000...1.000 V

|

|

|

|

Specification

|

Between -10.0 and 10.0 % the readout should fluctuate by at least 2 %

|

Between 0.000 and 1.000 V the voltage should fluctuate by about 0.3 V

|

|

|

|

Note

|

If readout does not match specification

=>Further notes,

Page 24-75

|

If readout does not match specification

=>Reading Display Group 033, Page 24-78

|

|

|

Further notes

If the readout in display zone 1 does not match the specification, or if the readout does not fluctuate by at least 2 %:

-

‒ Take car for a test drive to free lambda probe of any deposits, then repeat the test.

If the readout in display zone 1 still does not match the specification even after the test drive, or if the readout still does not fluctuate by at least 2 %:

-

‒ Test the basic voltage => Page 24-79.

-

‒ Test the lambda probe heating=> Page 24-81.

Reading Display Group 032

|

Display zone 1 / 2

|

Possible cause of fault

|

Fault remedy

|

|

Lambda learned

values between

-10.0 and -25.0 %

|

- Air leak in intake system (pressure side between turbocharger and intake manifold)

|

- Check intake system for leaks and eliminate unmetered air

=> Page 24-63

|

|

|

- Oil dilution

|

- Change oil or drive car

at moderate to high speeds on

out-of-town roads

|

|

|

- High oil consumption

|

|

|

|

- Air mass meter defective

|

- Test air mass meter

=> Page 24-55

|

|

|

- Solenoid valve for activated charcoal filter sticking in open position

|

- Test solenoid valve for activated

charcoal filter => Page 24-105

|

|

|

- Fuel pressure too high

|

- Test fuel pressure regulator

=> Page 24-26

|

|

|

- Injector leaking

|

- Test injectors => Page 24-32

|

|

|

- Lambda probe heating defective

- Lambda probe dirty

|

- Test lambda probe heating

=> Page 24-81

|

Reading Display Group 032

|

|

|---|

|

Display zone 1 / 2

|

Possible cause of fault

|

Fault remedy

|

|

Lambda learned

values between

10.0 and 25.0 %

|

- Unmetered air in intake tract

|

- Check intake system for leaks and eliminate unmetered air

=> Page 24-63

|

|

|

- Fuel pressure too low

|

- Test fuel pressure regulator

=> Page 24-26

|

|

|

- Lambda probe heating defective

|

- Test lambda probe heating

=> Page 24-81

|

|

|

- Injector not opening or only opening partially

|

- Test injectors => Page 24-32

|

|

|

- Solenoid valve for activated charcoal filter sticking

|

- Test solenoid valve for activated

charcoal filter => Page 24-105

|

Reading Display Group 033

|

|

|---|

|

Display zone 2

|

Possible cause of fault

|

Fault remedy

|

|

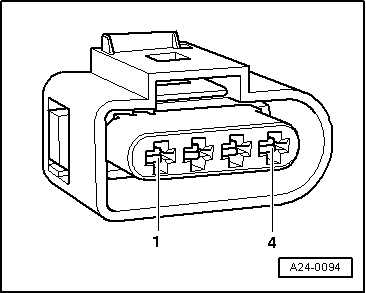

Approx. 0.450 V (constant)

|

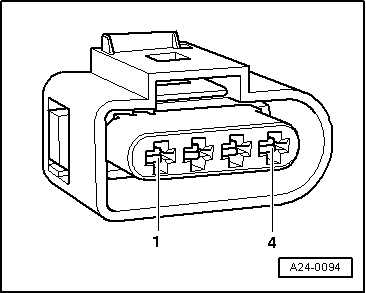

- Open circuit in wire 4 between lambda probe and control unit

|

- Test basic voltage => Page 24-79

|

|

|

- Open circuit in wire 3 between lambda probe and control unit

|

|

|

Approx. 0.200 V

(constant)

|

- Lambda probe defective

|

- Renew lambda probe

|

|

More than 1.100 V

|

- Short to positive in wire 4 between lambda probe and control unit

|

- Test lambda probe wiring => Page 24-80

|

|

Less than 0.150 V

|

- Short to earth in wire 4 between lambda probe and control unit

|

|

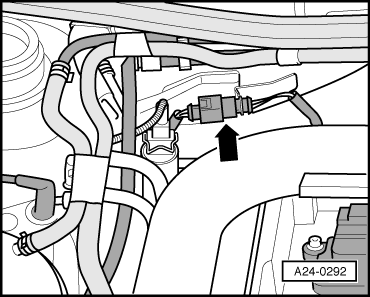

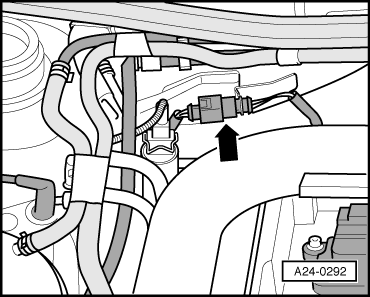

Testing basic voltage

|