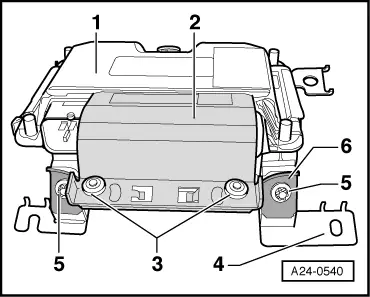

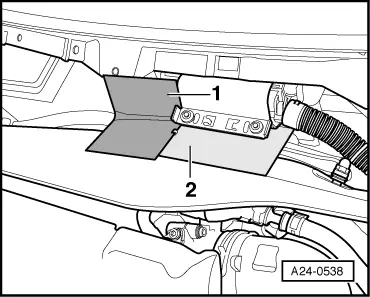

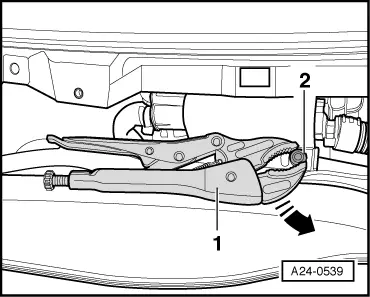

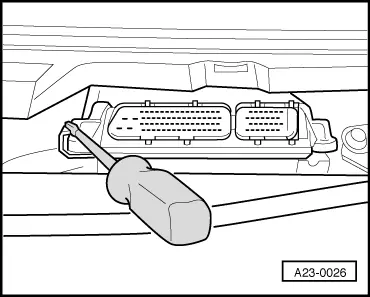

| To make the connectors at the engine control unit less accessible, the engine control unit -1- is bolted to a protective housing -4- by means of a locking element -2- and shear bolts -3-. |

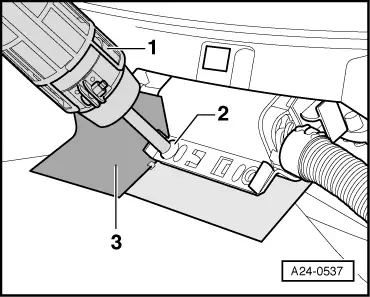

| To make it even more difficult to screw out the shear bolts, the threads are coated with locking fluid. |

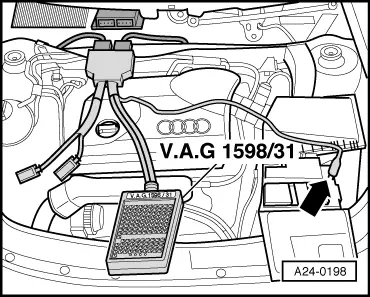

| The locking element -2- must be separated from the protective housing to enable the connectors to be unplugged from the engine control unit (e.g. when connecting the test box). This procedure is described in the following. |

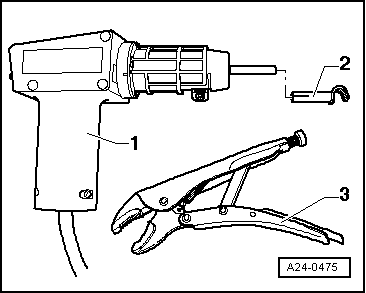

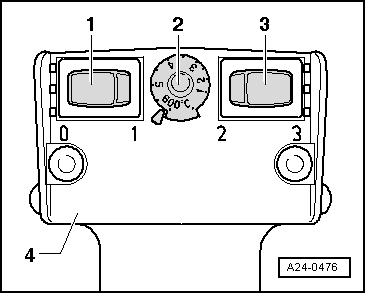

WARNING | Exact compliance with the following operations is essential so as not to damage (scorch) wiring, connectors, insulation and control units. Heed the operating instructions for the hot air blower. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note Note

Note

WARNING

WARNING