A3 Mk1

|

|

Installing Note: Always renew copper seals between cylinder head and injectors.

Tightening torque:

Checking |

| → Read measured value block, display group 13, Engine idling |

|

||

Notes:

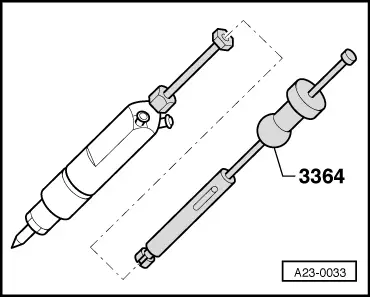

This engine is equipped with dual spring injectors. The fuel injection therefore takes place in 2 stages. |

|

||||||||

|

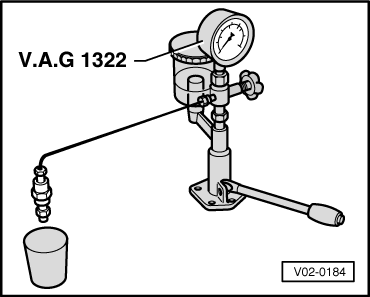

→ Testing injectors using V.A.G 1322 and pressure pipe V.A.G 1322/2. Important

When testing injectors, care should be taken to ensure that the jet of fuel does not come into contact with the hands, as the high pressure will cause the fuel to penetrate the skin and it could cause severe injuries.

Engine codes: AGR, AHF

Engine codes: ALH and ASV

Testing for leaks

|