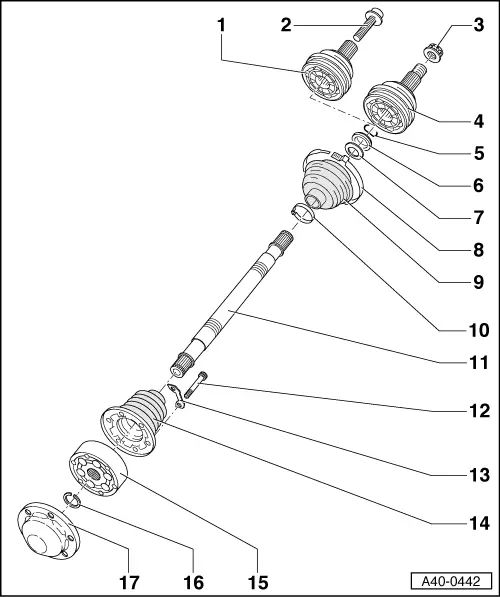

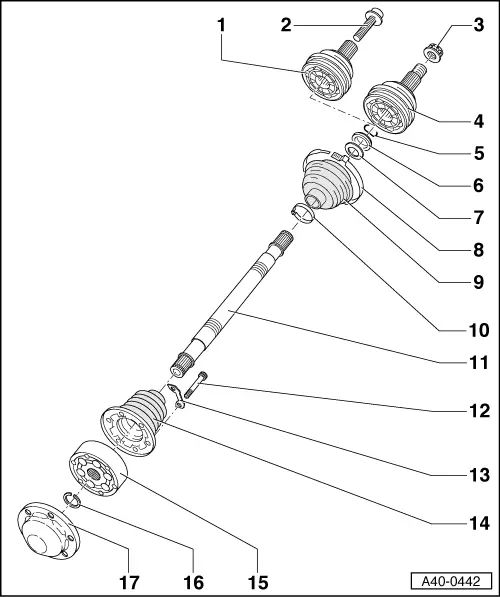

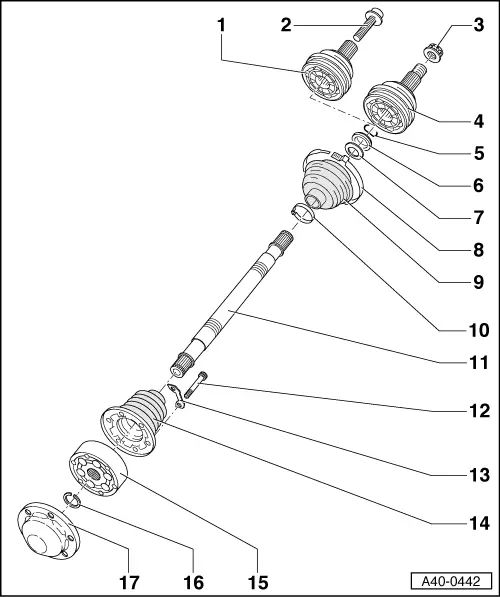

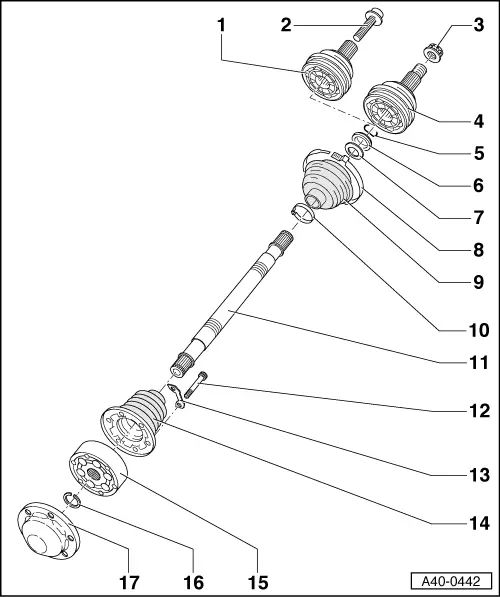

A3 Mk1

|

|

|

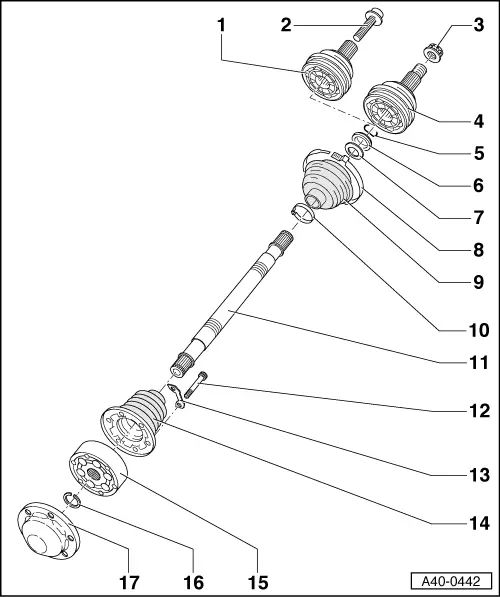

Exploded view of components

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

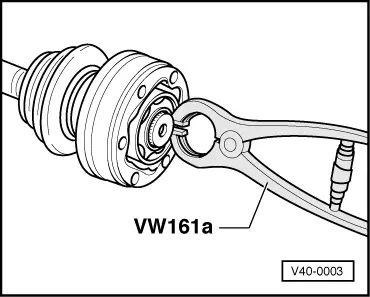

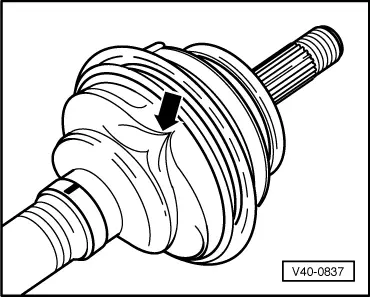

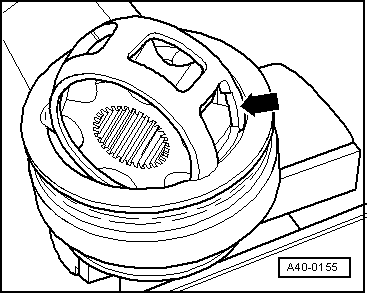

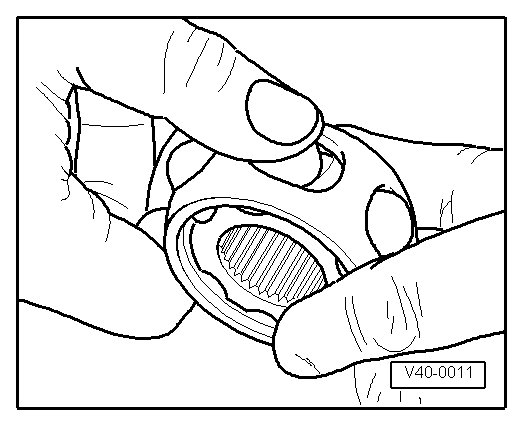

→ Fig.1 Removing and installing circlip |

|

|

|

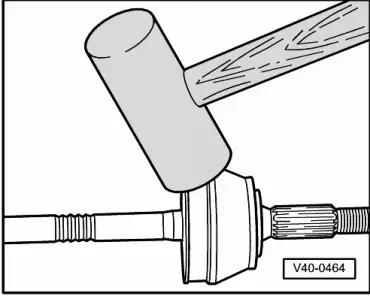

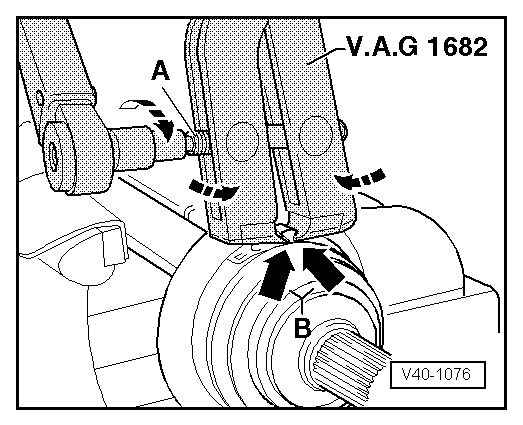

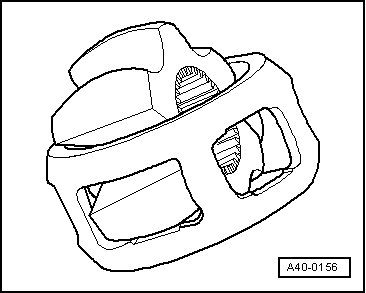

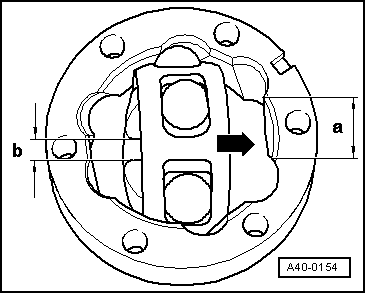

→ Fig.2 Removing outer constant velocity joint

|

|

|

|

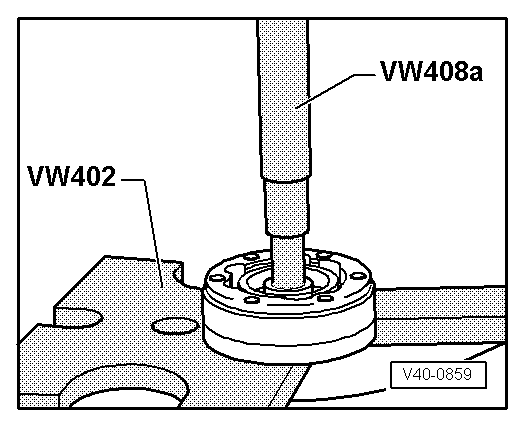

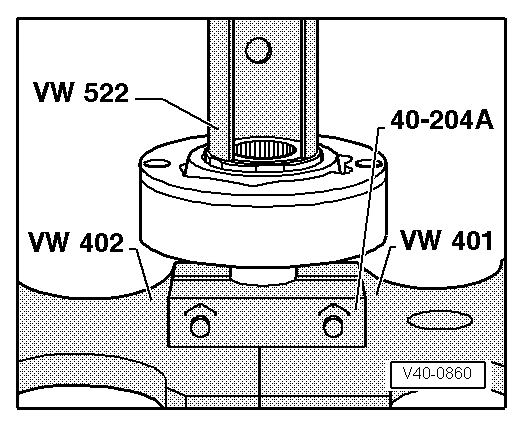

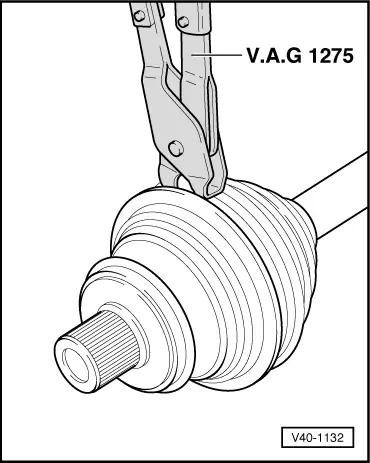

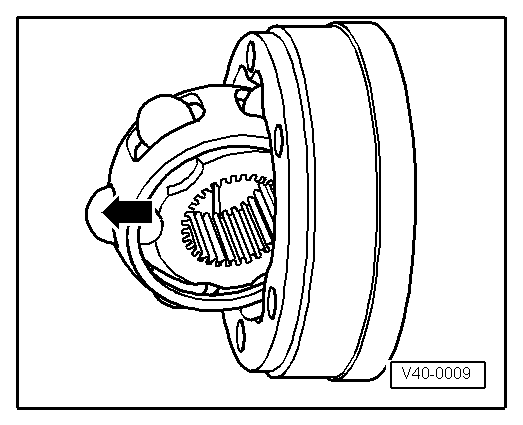

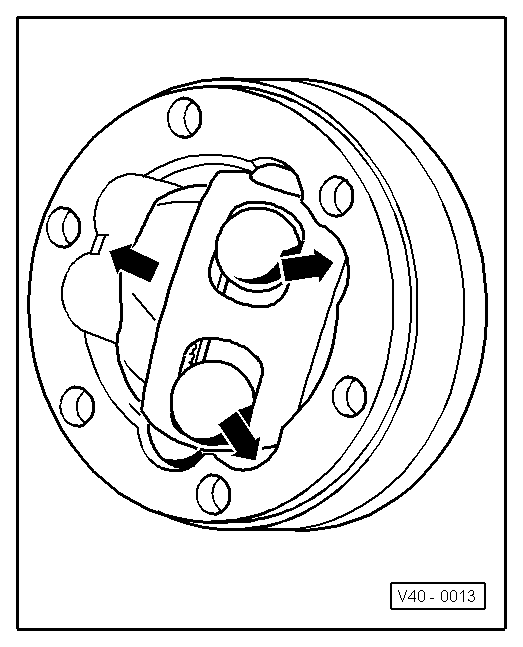

→ Fig.3 Pressing off inner constant velocity joint

|

|

|

|

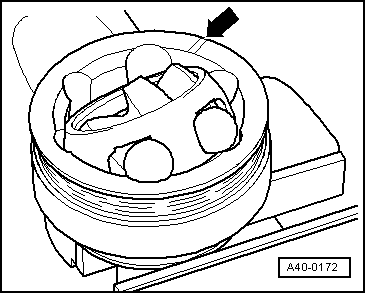

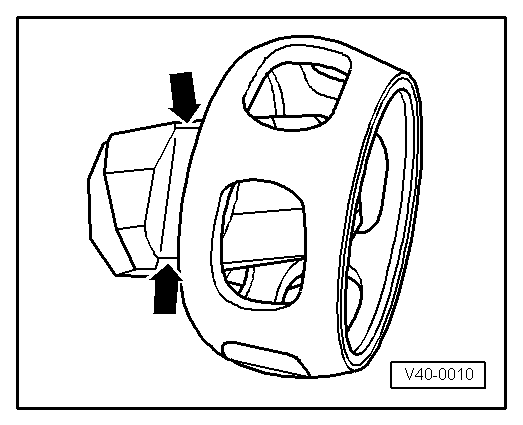

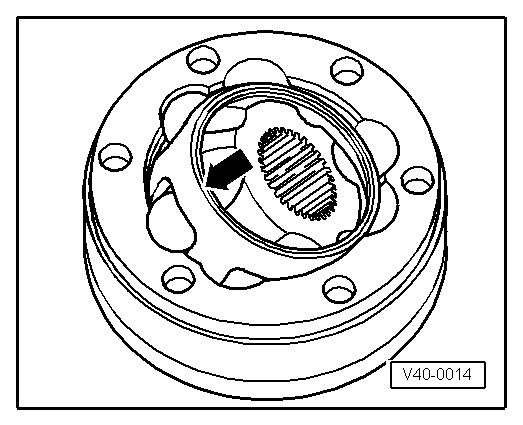

→ Fig.4 Pressing on inner constant velocity joint

Note: Chamfer at ID of ball hub (splines) must face contact collar of drive shaft. |

|

|

|

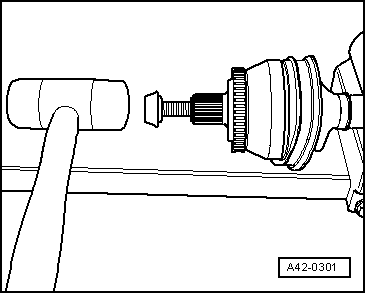

→ Fig.5 Fitting outer constant velocity joint with collared bolt

|

|

|

|

→ Fig.6 Coating sealing surface of cap with D 454 300 A2 |

|

|

|

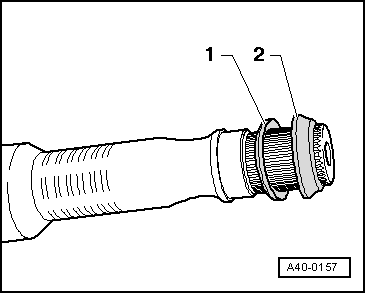

→ Fig.7 Installation position of spacer ring and dished washer at outer joint

|

|

|

|

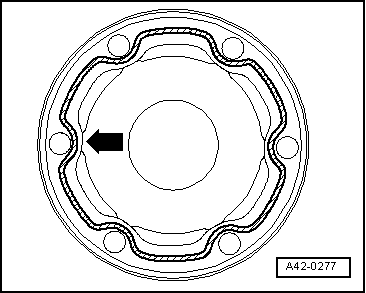

→ Fig.8 Venting rubber boot Boot is often squashed on positioning it on joint housing. This produces a vacuum in the boot, which causes a fold to form whilst driving -arrow-. Attention is therefore to be paid to the following:

|

|

|

|

→ Fig.9 Tensioning stainless-steel clamps for Hytrel boots

Notes:

|

|

|

|

→ Fig.10 Tensioning clamp for rubber boot |

|

|

|

Checking outer constant velocity joint The joint must be dismantled for replacing grease in the event of severe contamination or if ball contact surfaces are to be checked for wear and damage. Removing

|

|

|

|

|

|

Notes:

Installing Install in reverse order, paying attention to the following:

Note: Cage must be inserted in correct position.

Checking inner constant velocity joint The joint must be dismantled for replacing grease in the event of severe contamination or if ball contact surfaces are to be checked for wear and damage. Note: Ball hub and joint element are paired. Mark respective positions with a waterproof felt-tip pen prior to removal. |

|

|

|

Removing

|

|

|

Note: Excessive backlash in joint becomes apparent from load change jolts. Joint is then to be replaced. Smooth areas and running marks on balls do not necessitate joint replacement. |

|

|

|

Installing Install in reverse order, paying attention to the following:

|

|

|

|

Notes:

|

|

|

|

|

|

Checking operation of constant velocity joint Constant velocity joint has been correctly assembled if ball hub can be pushed back and forth by hand over entire length compensation range. |