|

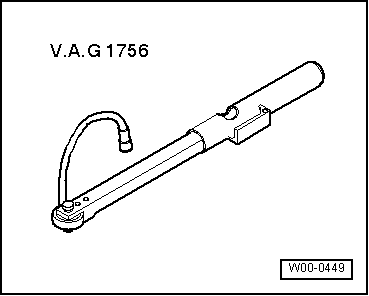

Special tools and workshop equipment required

-

◆ Angle measuring wrench V.A.G 1756

Unfastening twelve-point nut

-

‒ To avoid wheel bearing damage, do not unfasten twelve-point nut by more than 90°with vehicle still standing on its wheels.

-

‒ Raise vehicle such that wheels are off ground.

-

‒ Have second mechanic press brake.

-

‒ Unscrew twelve-point nut.

Tightening twelve-point nut on the following vehicles: 1.6 l; 1.8 l FWD (92 kW, 110 kW, 132 kW); 1.9 l TDI (66 kW, 81 kW)

-

‒ Replace twelve-point nut.

-

‒ Remove any paint remnants and/or corrosion at thread and splines of outer joint.

-

‒ Before fitting drive shaft, lubricate the following locations with polycarbamide grease, part no. G 052 142 A2:

-

‒ Splines of outer joint

-

‒ Thread of outer joint

-

‒ Contact surface of twelve-point nut

- Insert outer joint as far as possible into wheel hub splines.

- Pull outer joint with twelve-point nut into wheel hub until it makes contact with wheel bearing.

- Lower vehicle, making sure that wheels do not as yet come into contact with ground.

Note:

Wheels must not be in contact with ground when tightening drive shaft as otherwise wheel bearing could be damaged.

-

‒ Have second mechanic press brake.

-

‒ Tighten twelve-point nut to 200 Nm.

-

‒ Slacken off twelve-point nut by 360°(one turn).

-

‒ Tighten twelve-point nut to 50 Nm.

-

‒ Set vehicle down on its wheels.

-

‒ Give twelve-point nut further 60° turn.

Tightening twelve-point nut on the following vehicles: 1.8 l 4WD (110 kW, 132 kW, 154 kW, 165 kW); 1.9 l TDI FWD and 4WD (74 kW, 96 kW)

-

‒ Replace twelve-point nut.

-

‒ Remove any paint remnants and/or corrosion at thread and splines of outer joint.

-

‒ Before fitting drive shaft, lubricate the following locations with polycarbamide grease, part no. G 052 142 A2:

-

‒ Splines of outer joint

-

‒ Thread of outer joint

-

‒ Contact surface of twelve-point nut

-

‒ Insert outer joint as far as possible into wheel hub splines.

-

‒ Pull outer joint with twelve-point nut into wheel hub until it makes contact with wheel bearing.

-

‒ Lower vehicle, making sure that wheels do not as yet come into contact with ground.

Note:

Wheels must not be in contact with ground when tightening drive shaft as otherwise wheel bearing could be damaged.

-

‒ Have second mechanic press brake.

-

‒ Tighten twelve-point nut to 190 Nm.

-

‒ Set vehicle down on its wheels.

-

‒ Give twelve-point nut further 90° turn.

|