| –

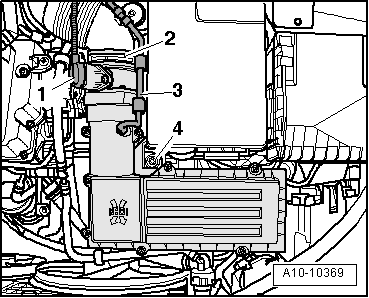

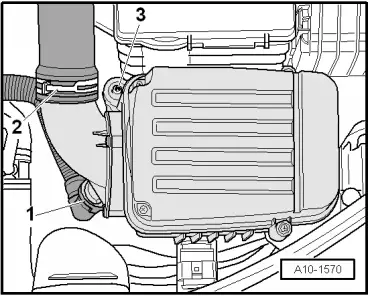

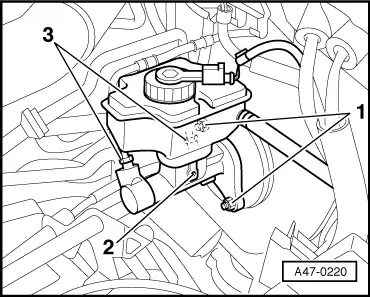

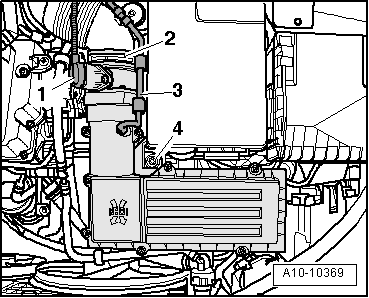

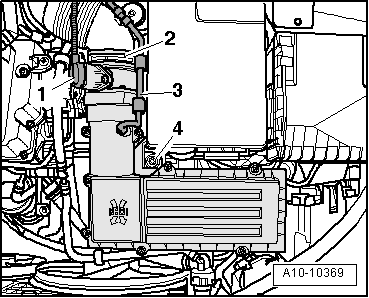

| Connect air duct at clamp -2-. |

| –

| Install cover on air cleaner housing. |

| –

| Connect breather hose -3-. |

| –

| Plug in electrical connector -1- on air mass meter. |

| –

| Install engine cover panel. |

| –

| Bleed brake system: ABS/ESP Mark 60 / Mark 70 → Chapter. |

| –

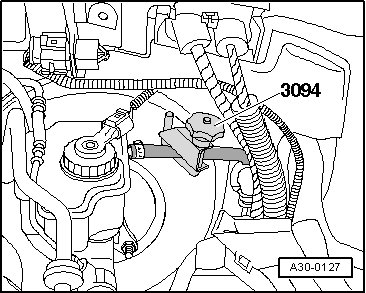

| On vehicles with ABS/ESP, start basic setting for brake pressure sender 1 -G201-. |

| To do so, use the vehicle diagnosis, testing and information system -VAS 5051 x - or -VAS 5052-. |

| –

| Carry out ESP road test and system test. |

| To do so, use the vehicle diagnosis, testing and information system -VAS 5051 x - or -VAS 5052-. |

| –

| Brake system (Repair group 01; 45) |

| –

| 01 - Self-diagnosis compatible systems |

| –

| 03 - Brake electronics ABS/ESP Mark 60 |

| –

| J104 - Control unit for ABS/TCS/ESP, Functions |

|

|

|