A3 Mk2

| Removing and installing input shaft, output shaft (pinion shaft), differential, selector mechanism and selector forks |

| Special tools and workshop equipment required |

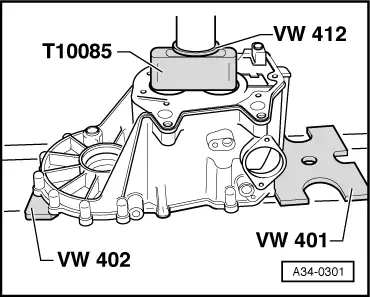

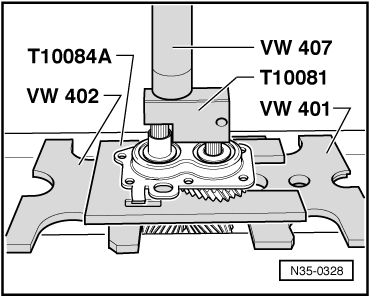

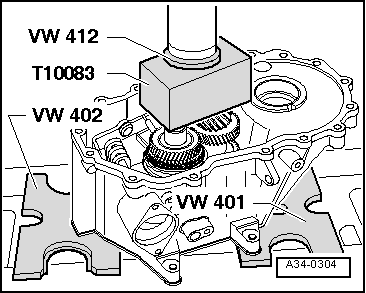

| t | Thrust plate -VW 401- |

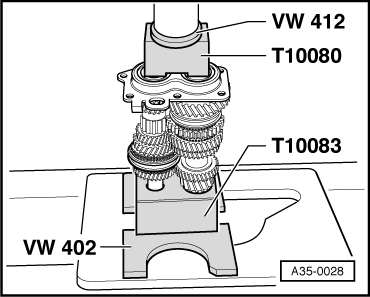

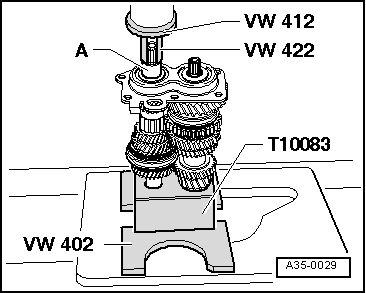

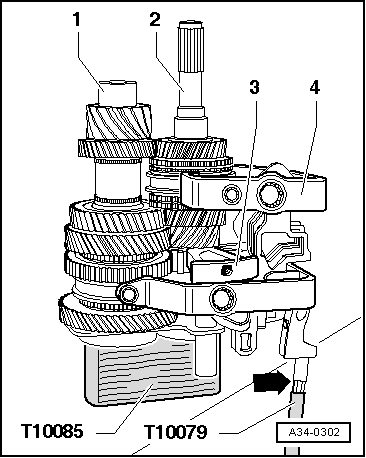

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

| t | Press tool -VW 412- |

| t | Tube -VW 422- |

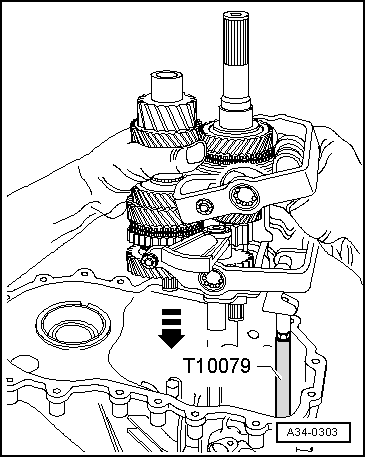

| t | Guide pin -T10079- |

| t | Thrust piece -T10080- |

| t | Thrust piece -T10081- |

| t | Thrust block -T10083- |

| t | Thrust plate -T10084 A- |

| t | Thrust piece -T10085- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

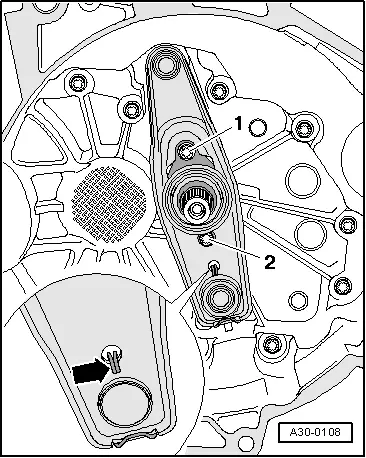

| Circlip thickness (mm) | ||

| 2.00 | 2.10 | 2.20 |

|

|

|

WARNING

WARNING