A3 Mk2

Note

Note

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

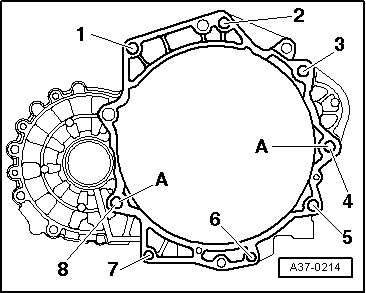

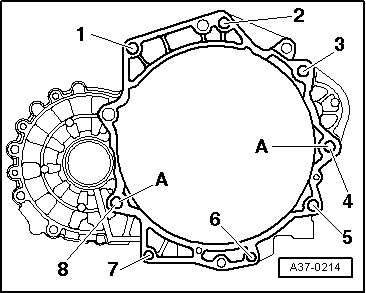

| Item | Bolt | Nm |

| 1, 2 | M12×65 | 80 |

| 3 → Note, 4 → Note | M12×135 | 80 |

| 5 … 7 | M10×60 | 40 |

| 8 | M12×90 | 65 |

|

|

|