A3 Mk2

| Dismantling and assembling differential |

| Special tools and workshop equipment required |

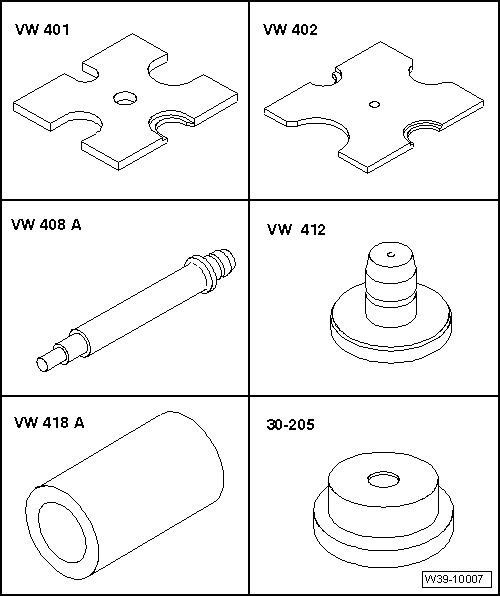

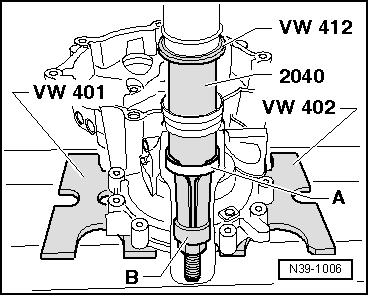

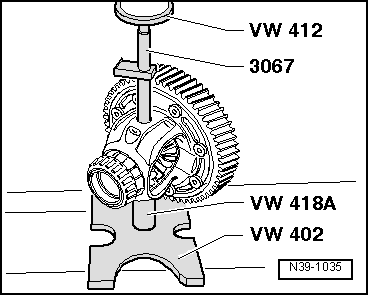

| t | Thrust plate -VW 401- |

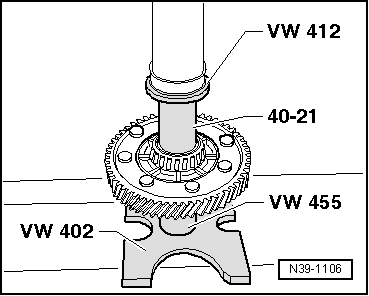

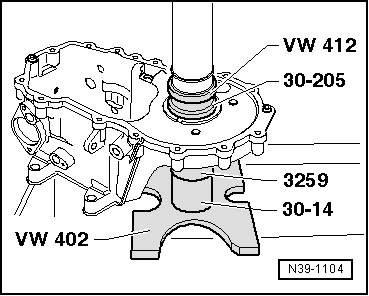

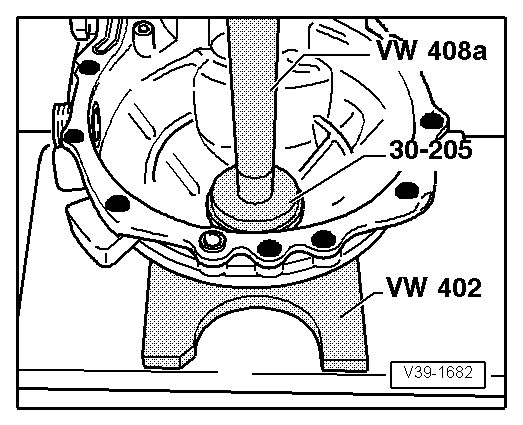

| t | Thrust plate -VW 402- |

| t | Press tool -VW 408 A- |

| t | Press tool -VW 412- |

| t | Tube -VW 418 A- |

| t | Thrust plate -30 - 205- |

| t | Installing sleeve -VW 455- |

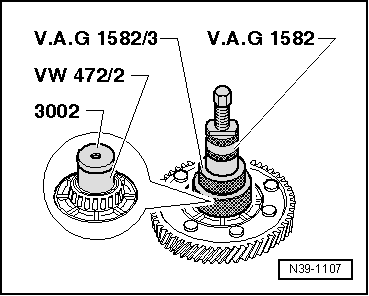

| t | Spacer sleeve -VW 472/2- |

| t | Press tool -40 - 21- |

| t | Tube -30 - 14- |

| t | Tube -2040- |

| t | Thrust piece -3002- |

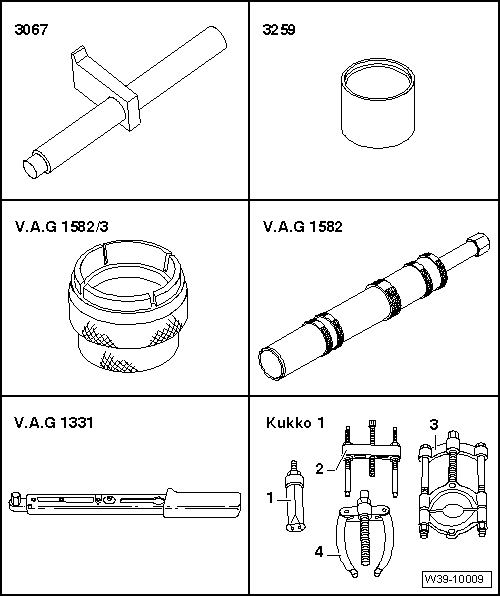

| t | Counterhold tool -3067- |

| t | Tube -3259- |

| t | Adapter -V.A.G 1582/3- |

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Internal puller -1 - Kukko 21/7- |

| t | Counter-support -4 - Kukko 22/2- |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|