A3 Mk2

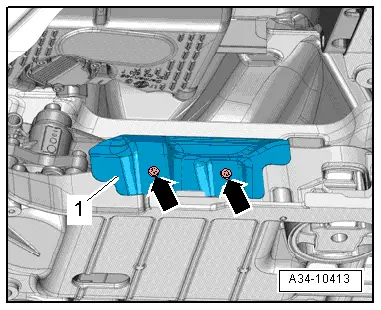

| Removing gearbox (vehicles with 1.4 ltr. TFSI engine) |

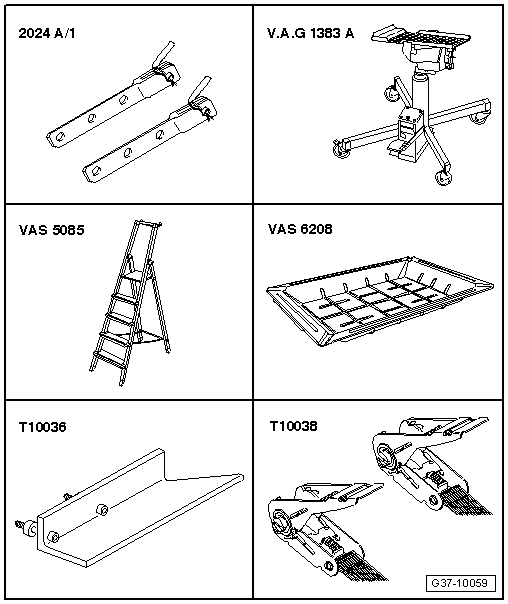

| Special tools and workshop equipment required |

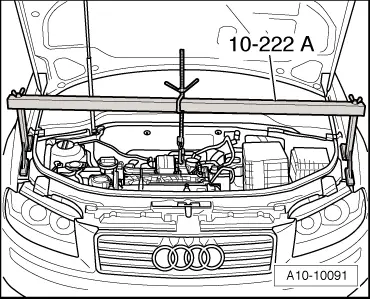

| t | Support bracket -10 - 222 A- |

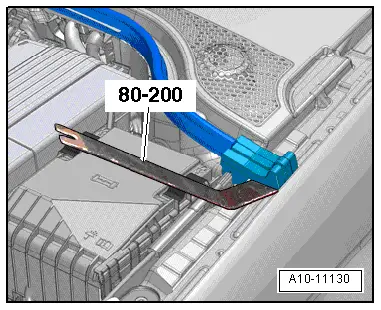

| t | Removal lever -80 - 200- |

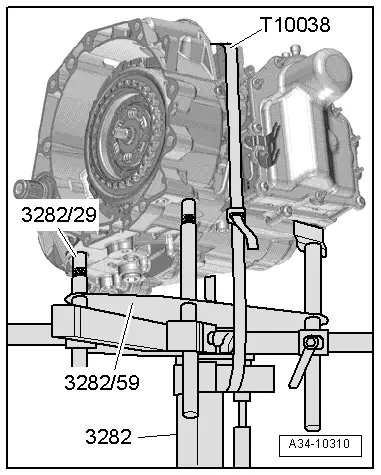

| t | Gearbox support -3282- |

| t | Pin -3282/29- |

| t | Adjustment plate -3282/59- |

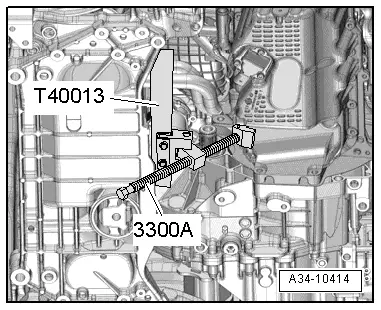

| t | Engine support -3300 A- |

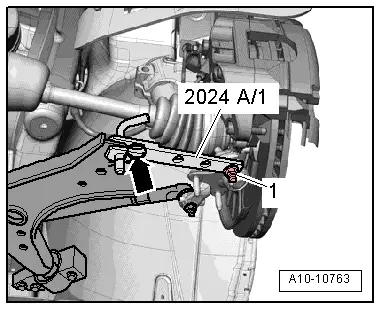

| t | Extension -2024 A /1- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Stepladder -VAS 5085- |

| t | Drip tray for workshop hoist -VAS 6208- |

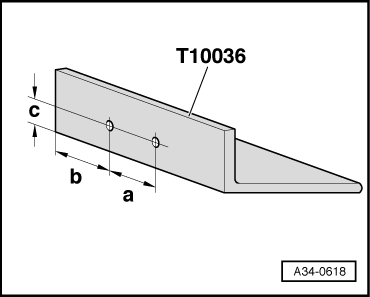

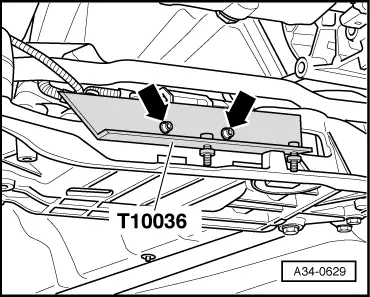

| t | Support -T10036- |

| t | Tensioning strap -T10038- |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Caution

Caution WARNING

WARNING