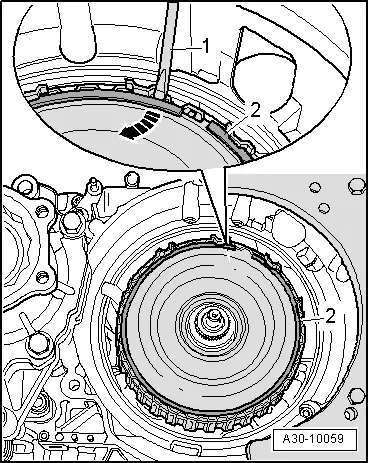

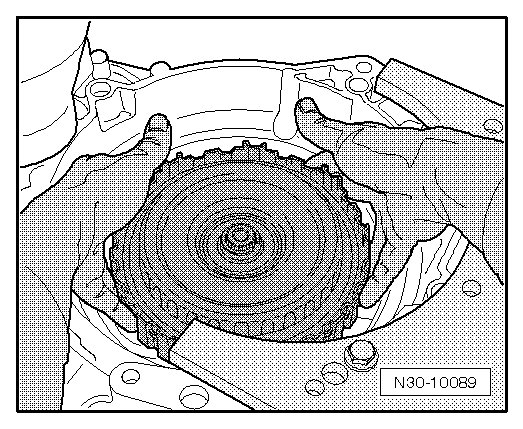

| Installing multiple clutch |

Caution | t

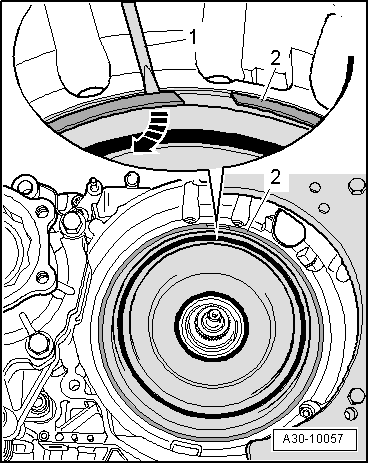

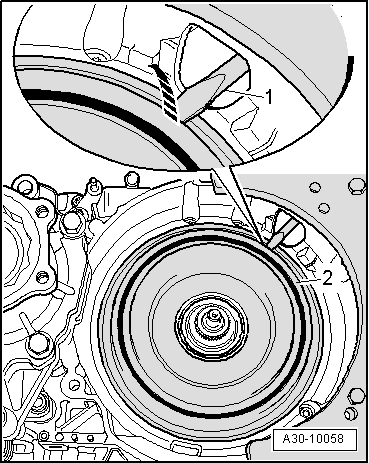

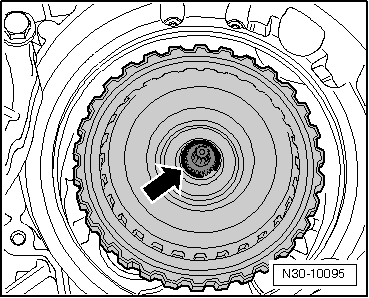

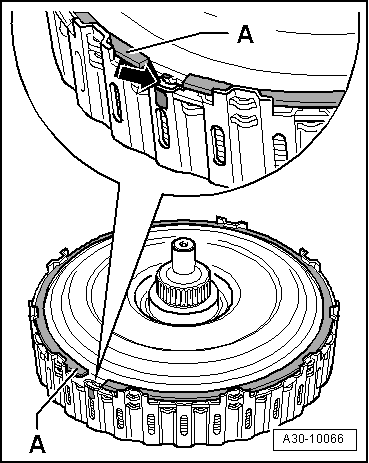

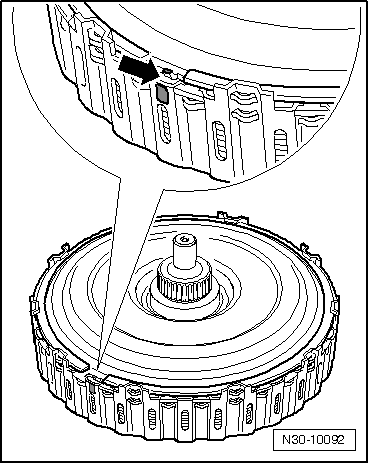

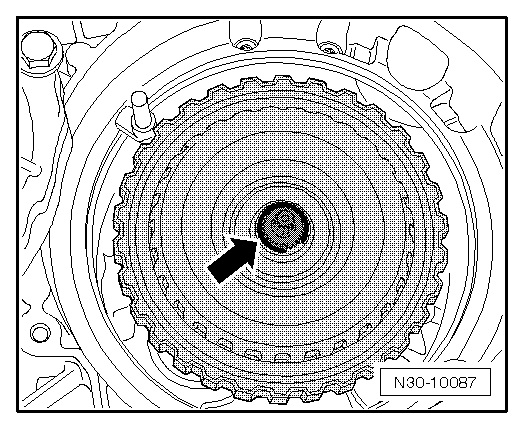

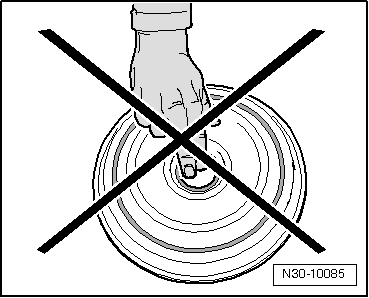

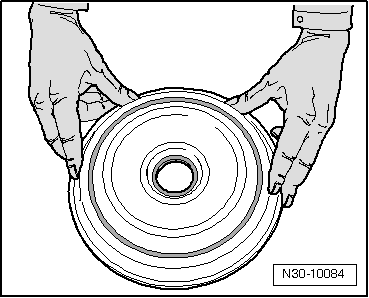

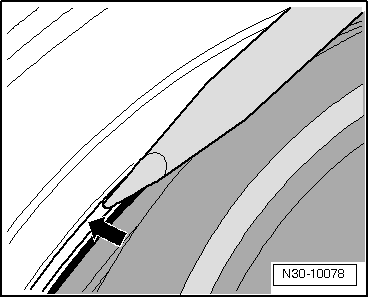

| The drive plate of a new clutch is not secured with a circlip; it is only a “close fit” in the clutch. |

| t

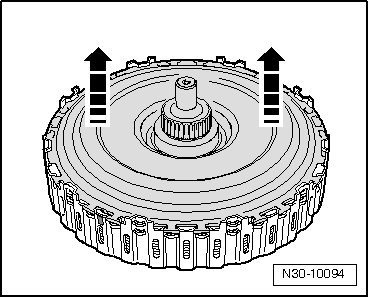

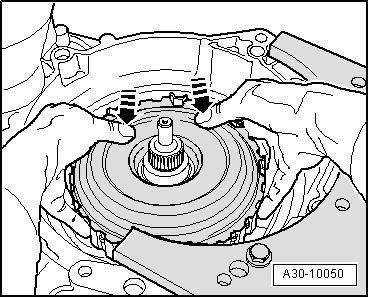

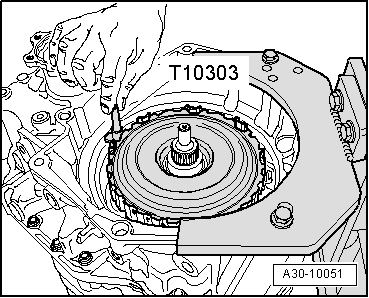

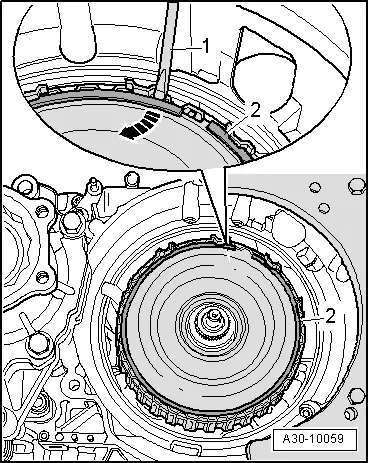

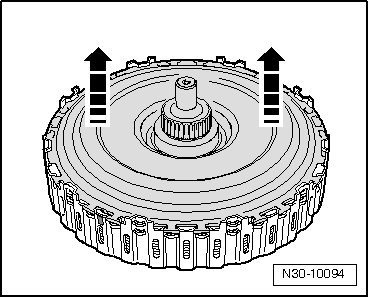

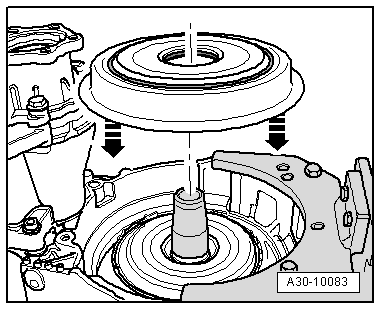

| While carrying out the following steps you must therefore hold the drive plate by pressing it into the outer plate carrier with both thumbs. |

| t

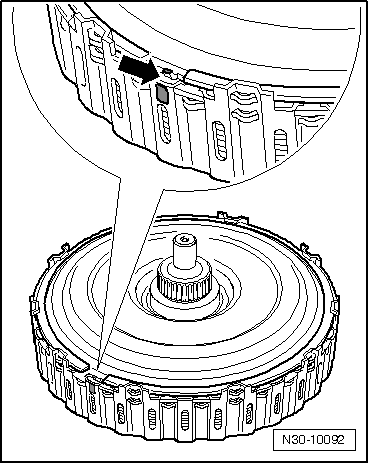

| The drive plate must remain engaged between the splines of the outer plate carrier. |

| t

| If the drive plate comes loose, the clutch plates can slip out of position inside the multiple clutch unit. If this happens, it may not be possible to adjust the multiple clutch correctly during installation. |

|

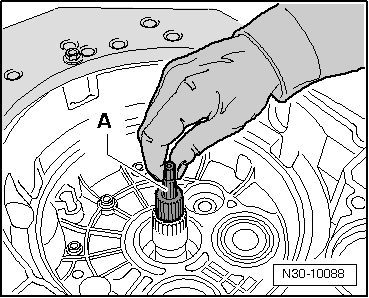

| –

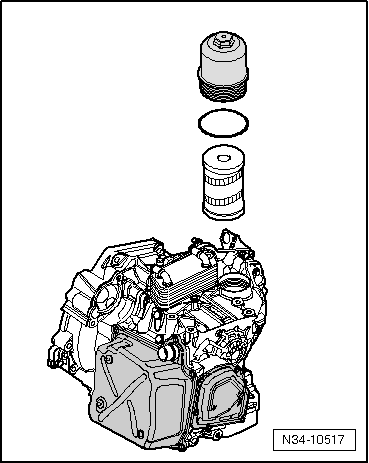

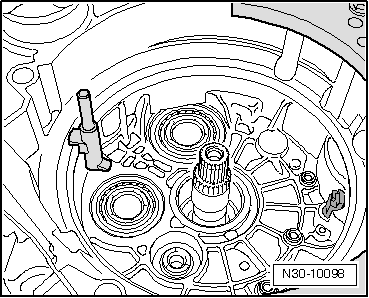

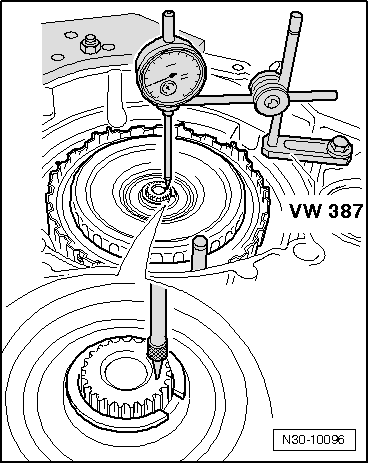

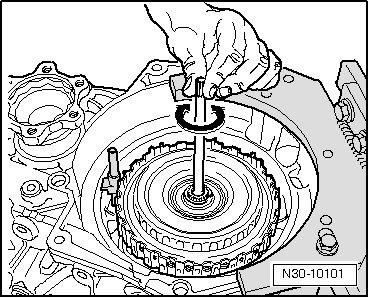

| Take the circlip out of the packaging. |

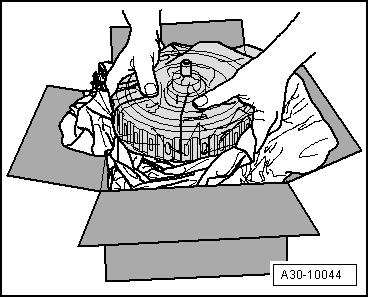

| –

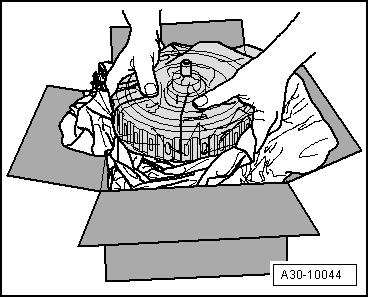

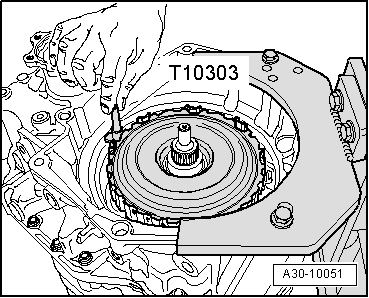

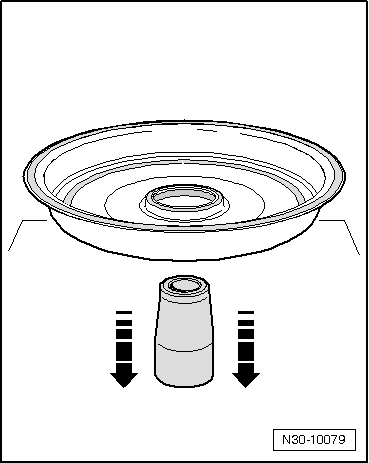

| Take the clutch for direct shift gearbox out of the packaging, at the same time pressing the drive plate into the outer plate carrier with both thumbs. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution