A3 Mk2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

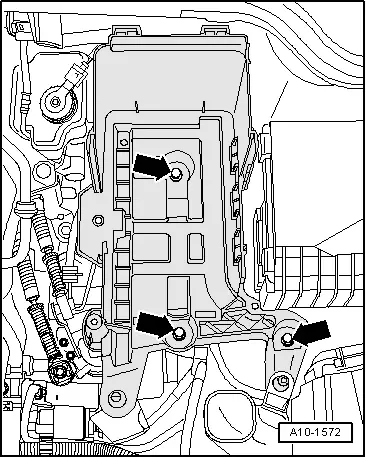

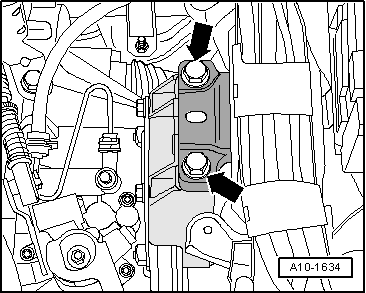

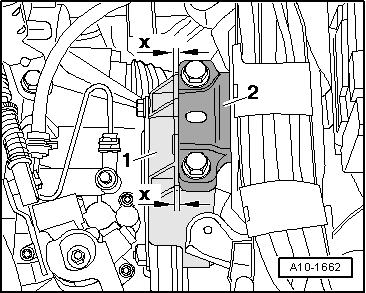

| Component | Nm | ||||

| Support arm to engine support | 60 + 90° 1)2) | ||||

| Support arm to gearbox support | 60 + 90° 1)2) | ||||

| |||||

Caution

Caution