| –

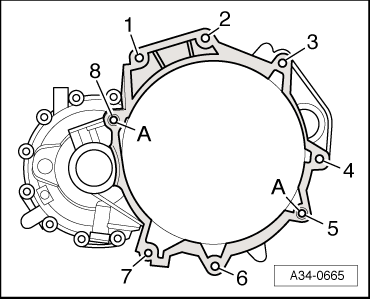

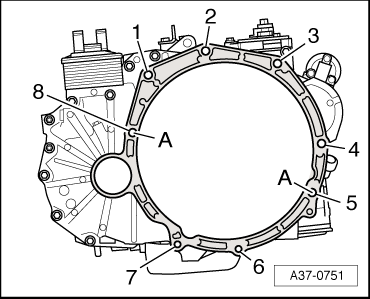

| Check whether dowel sleeves for centring the engine/gearbox assembly are fitted in the cylinder block; install if necessary. |

| –

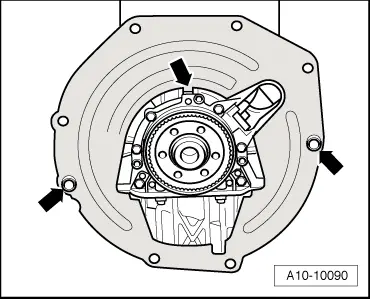

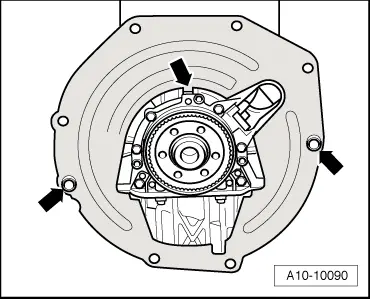

| Engage intermediate plate on sealing flange and slip onto dowel sleeves -arrows-. |

| Vehicles with manual gearbox: |

| –

| Clean splines of input shaft and (on used clutch plates) splines of hub. |

| –

| Remove any traces of corrosion and apply a very thin coat of grease -G 000 100- onto splines. |

| –

| Then move clutch plate back and forth on input shaft until the hub moves smoothly on the shaft. Remove any excess grease. |

| –

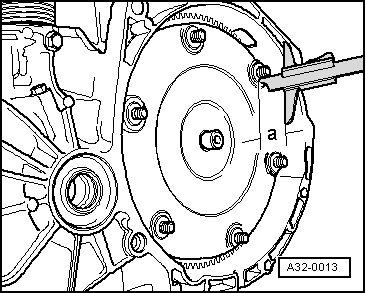

| Check that clutch plate is correctly centred → Rep. Gr.30. |

| –

| Check clutch release bearing for wear, renew if necessary. |

| –

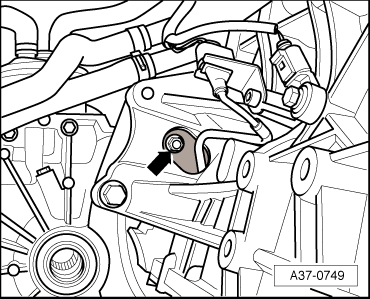

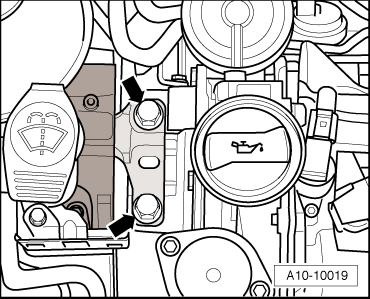

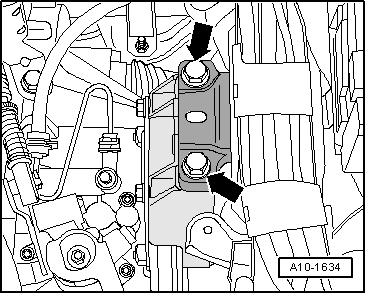

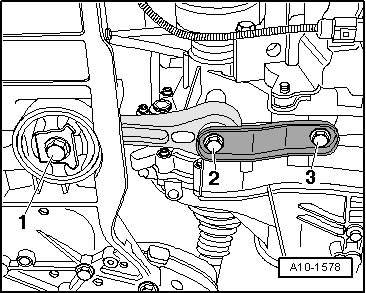

| Bolt gearbox to engine. |

Note | t

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricant such as engine oil or gearbox oil may be used, but do not use lubricant containing graphite. |

| t

| Do not use degreased parts. |

| t

| Tolerance for tightening torques ± 15%. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution