| –

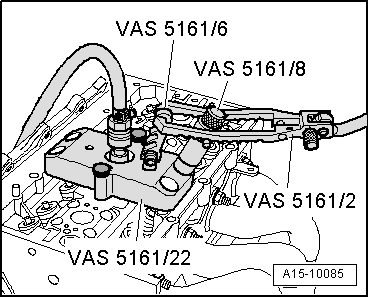

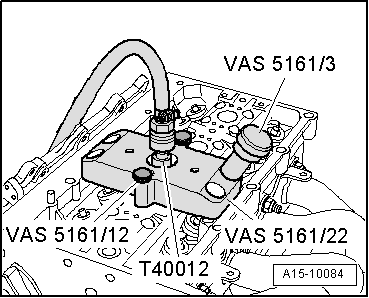

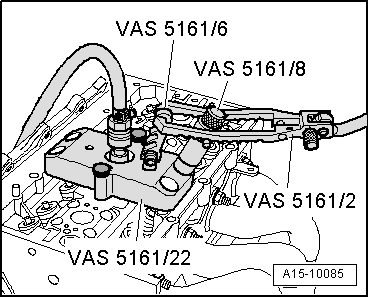

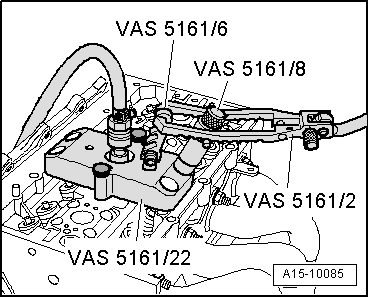

| Screw snap-in device -VAS 5161/6- with engaging fork -VAS 5161/5- into guide plate -VAS 5161/22-. |

| –

| Insert assembly cartridge -VAS 5161/8- into guide plate -VAS 5161/22-. |

| –

| Attach pressure fork -VAS 5161/2- to snap-in device -VAS 5161/6- and push assembly cartridge -VAS 5161/8- down. |

| –

| At the same time, turn knurled screw of assembly cartridge -VAS 5161/8- clockwise until ends engage in valve cotters. |

| –

| Move knurled screw back and forth slightly; the valve cotters are thus forced apart and enter into cartridge. |

| –

| Release the pressure fork. |

| –

| Remove assembly cartridge -VAS 5161/8-. |

| –

| Unbolt guide plate -VAS 5161/22- and move to side. |

| l

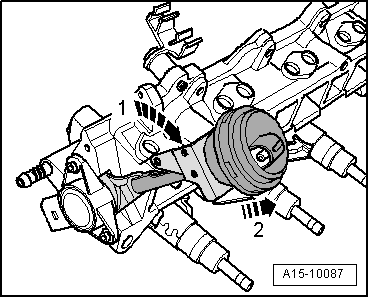

| The compressed air hose remains connected. |

| –

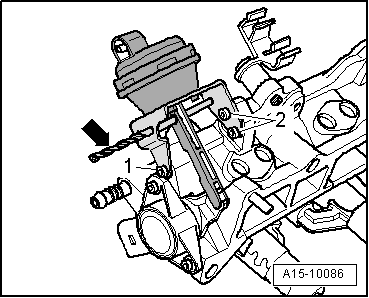

| Remove valve spring with valve spring plate. |

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING