A3 Mk2

| Checking valve timing |

| Special tools and workshop equipment required |

| t | Spark plug socket and extension -3122 B- |

| t | Torque wrench -V.A.G 1331- |

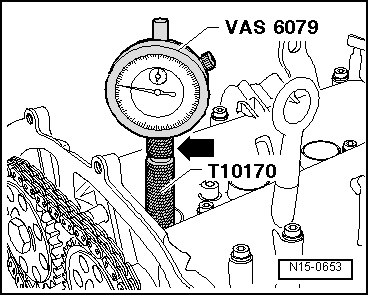

| t | Dial gauge -VAS 6079- |

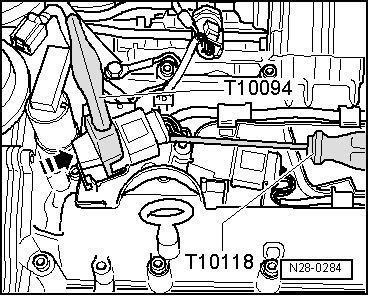

| t | Puller -T10094- |

| t | Adapter for dial gauge -T10170- |

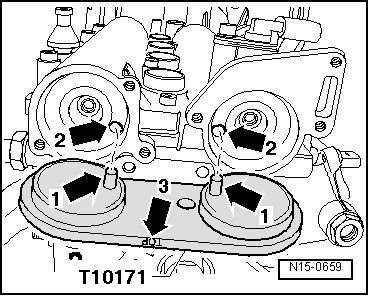

| t | Camshaft clamp -T10171- |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

| Component | Nm |

| Sealing caps to camshaft housing | 10 |