| –

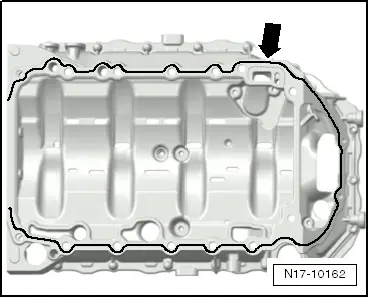

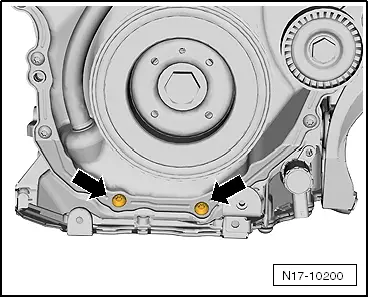

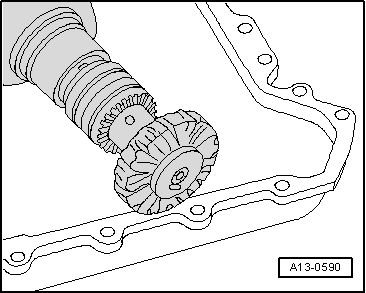

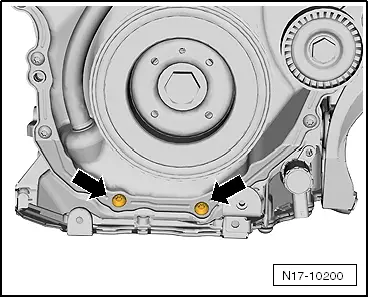

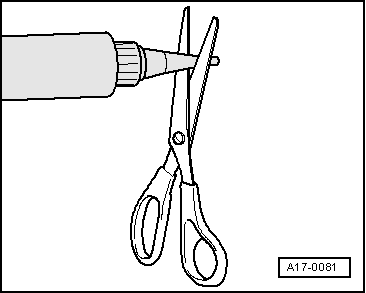

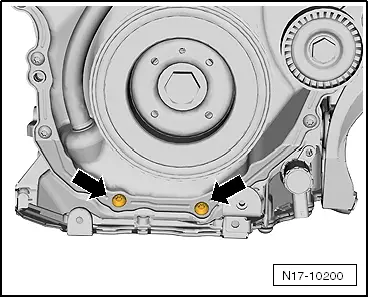

| Remove residual sealant at sump (top section) and timing chain cover (bottom) e.g. using a rotating plastic brush. |

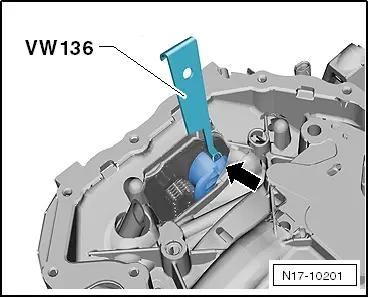

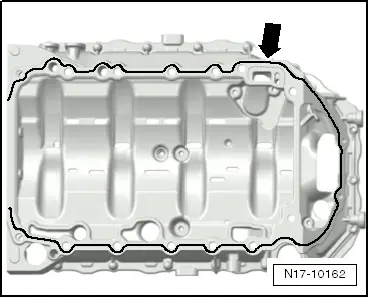

Note | Check if timing chain cover is deformed. For this purpose, first fit sump (top section) without sealant and determine gap between cover and sump (top section). If the cover is deformed and cannot be straightened, renew cover after installing sump (top section). |

| –

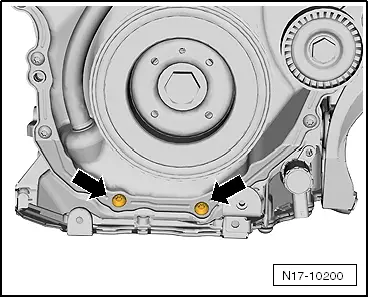

| Clean sealing surfaces; they must be free of oil and grease. |

| –

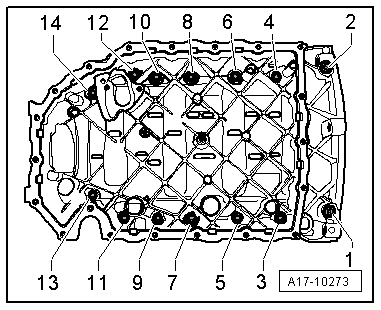

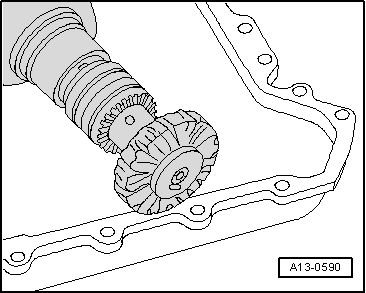

| Check oil channels in sump (top section) and crankcase for contamination. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note