A3 Mk2

| Removing and installing sump with balance shaft assembly and oil pump, engine code AXW, BLX, BHD, BLY, BLR, BMB |

| Special tools and workshop equipment required |

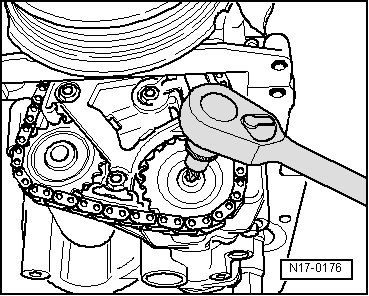

| t | T-bar and socket, 10 mm -3185- |

| t | Allen key, long reach -T10058- |

| t | Torque wrench -V.A.G 1331- |

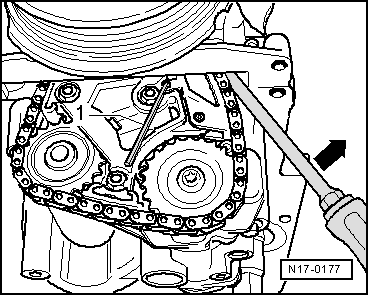

| t | Flat scraper |

Note

Note

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

| Component | Nm | |

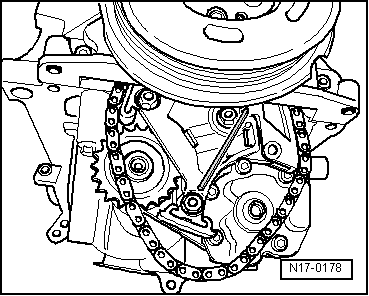

| Balance shaft assembly | 15 + 90° 1)2) | |

| Chain sprocket to oil pump | 20 + 90° 1)2) | |

| Oil pipe to balance shaft assembly | 10 | |

| Sump to cylinder block | 15 | |

| Sump to gearbox | 45 | |

| Oil drain plug | 30 | |

|