| –

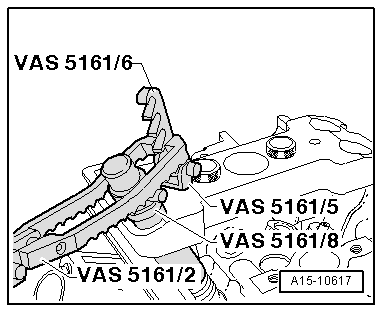

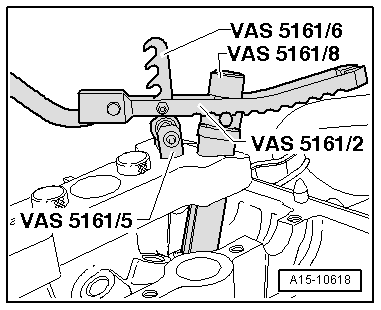

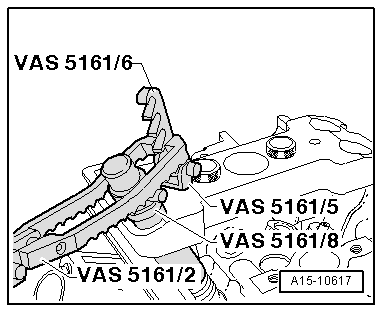

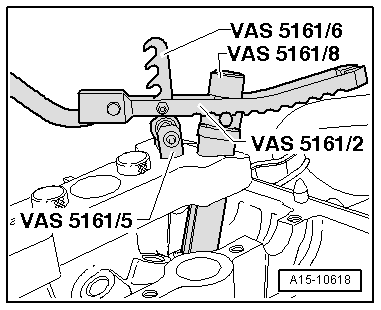

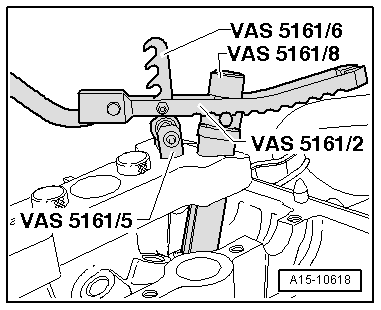

| Engage pressure fork -VAS 5161/2- at snap-in device, as shown in illustration. |

| Continuation for both sides: |

| –

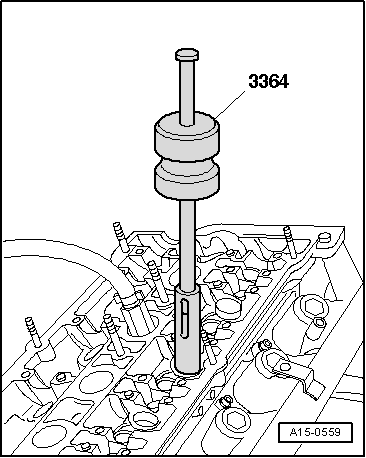

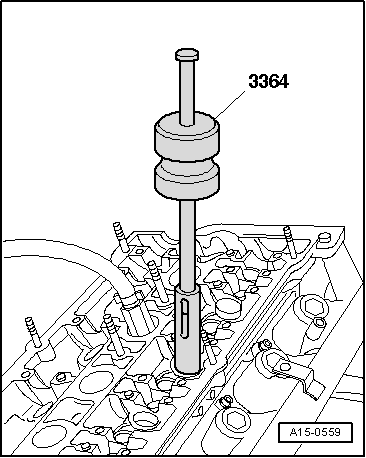

| Press down with pressure fork for assembly cartridge. |

| –

| At the same time, turn knurled screw of assembly cartridge clockwise until tips engage in valve cotters. |

| –

| Turn knurled screw in both directions. |

| l

| The valve cotters are forced apart and are taken up by the cartridge. |

| –

| Take out assembly cartridge. |

| –

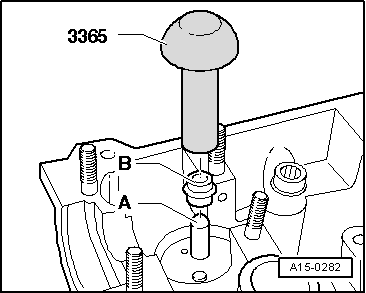

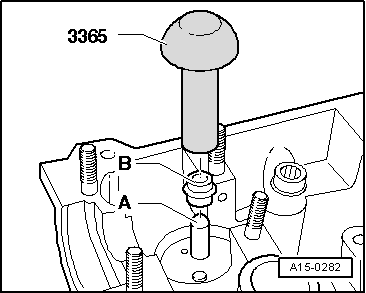

| Detach guide plate and turn to one side. |

| –

| Detach valve spring with valve spring plate. |

|

|

|