| –

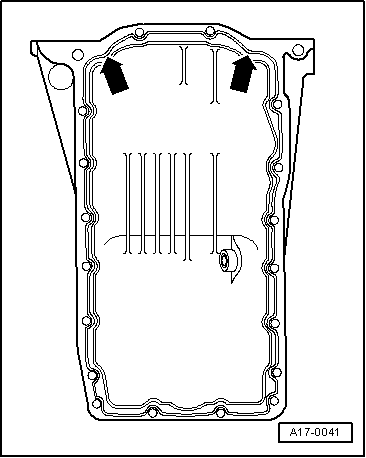

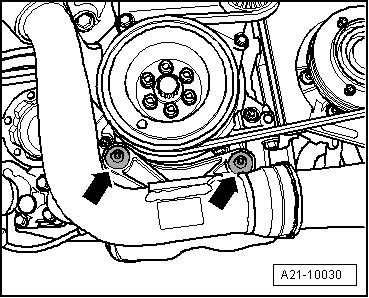

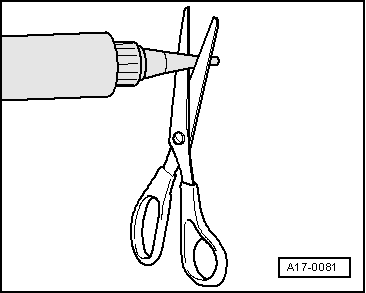

| Apply the bead of silicone sealant onto the clean sealing surface of the sump, as illustrated. |

| t

| Thickness of sealant bead: 2 ... 3 mm |

Note | t

| The sump must be installed within 5 minutes after applying the silicone sealant. |

| t

| The bead of sealant must not be thicker than specified, otherwise excess sealant can enter the sump and obstruct the strainer in the oil intake pipe. |

| t

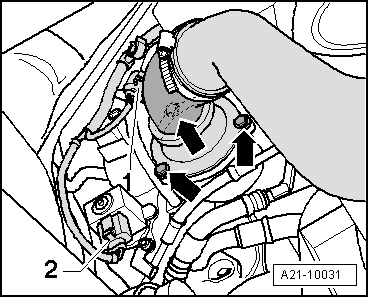

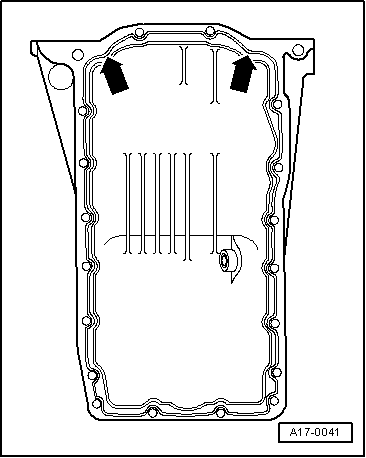

| Take particular care when applying sealant bead in area of rear sealing flange -arrows- as shown in this figure. |

| –

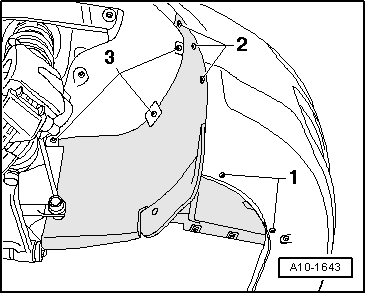

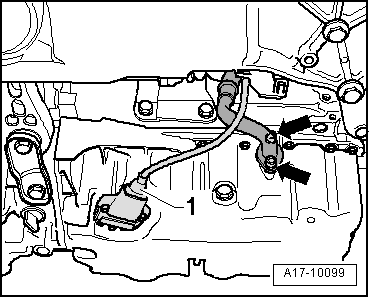

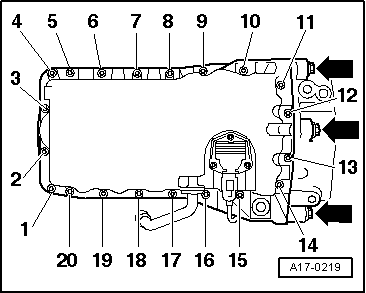

| Fit sump immediately and tighten bolts as follows; tightening sequence → Fig. |

Note | t

| When installing sump with engine removed from vehicle, ensure that sump is positioned flush with cylinder block at flywheel end. |

| t

| After fitting sump assembly, the sealant must dry for approx. 30 minutes. Then (and only then) fill the engine with engine oil. |

| –

| Fill up with engine oil and check oil level. |

| The remaining installation steps are carried out in the reverse sequence. Note the following points: |

| –

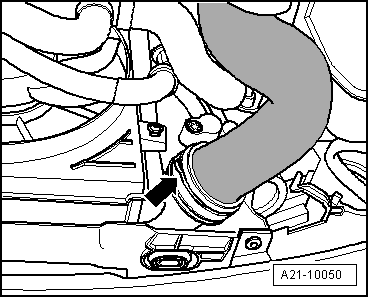

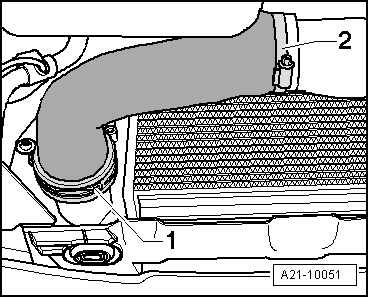

| Install air pipes with plug-in connectors → Chapter. |

|

|

|

Note

Note

Note

Note Note

Note

WARNING

WARNING