| –

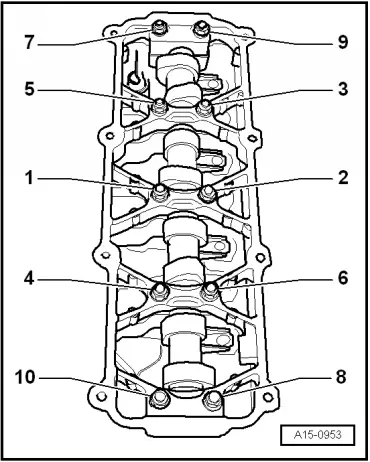

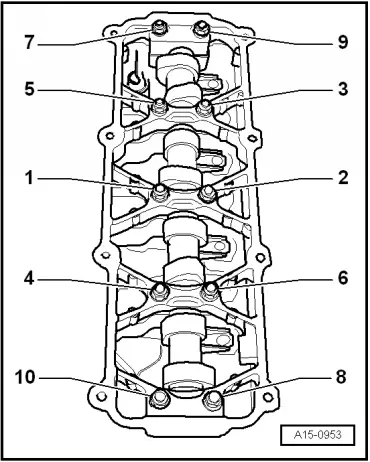

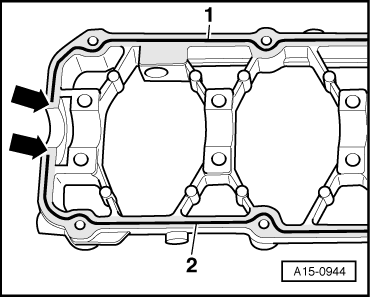

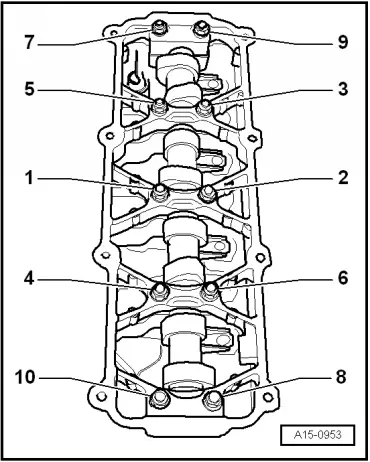

| Fit retaining frame and lightly tighten nuts -3, 4, 5, 6- diagonally in several stages. |

| –

| Then tighten nuts -1, 2, 7, 8, 9, 10- lightly. |

| –

| Finally tighten nuts to specified torque in the sequence -1 ... 10-. |

| –

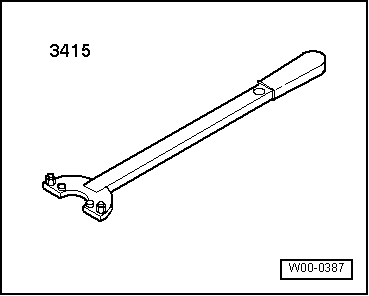

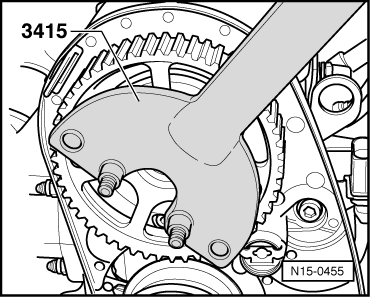

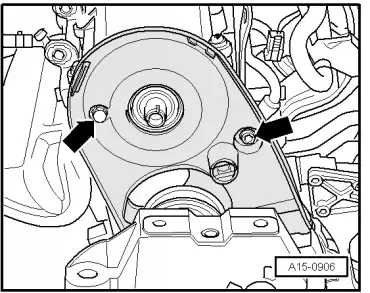

| Install toothed belt (adjust valve timing) → Anchor. |

Note | t

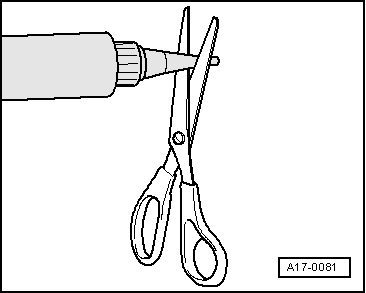

| After fitting retaining frame and cylinder head cover, allow sealant to dry for approx. 30 minutes. |

| t

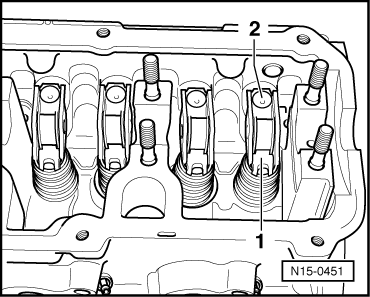

| After installing the camshaft, the engine must NOT be started for about 30 minutes. Hydraulic valve compensation elements have to settle (otherwise valves will strike pistons). |

| t

| After working on the valve gear, turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING