A3 Mk2

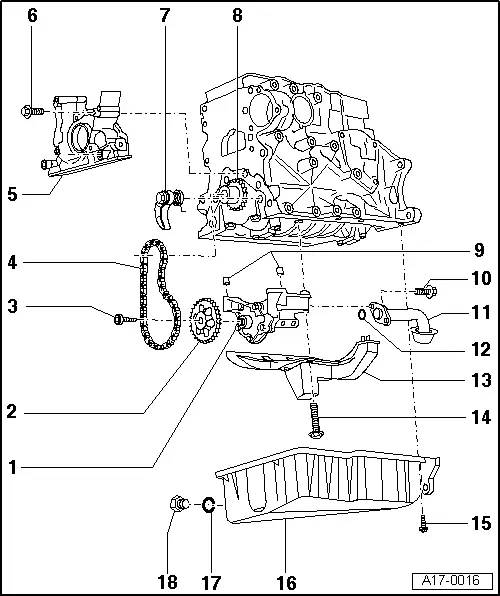

| Sump, oil pump - exploded view |

| 1 - | Oil pump |

| q | With pressure relief valve (12 bar) |

| q | Removing and installing → Chapter |

| q | Before installing, check that the two dowel sleeves → Item for centralising oil pump/cylinder block are fitted |

| q | Renew if running surfaces and gears are scored |

| q | Tightening torque for oil pump cover to oil pump housing: 10 Nm |

| 2 - | Chain sprocket for oil pump |

| q | Sprocket can only be fitted on oil pump shaft in one position. |

| 3 - | 20 Nm + 90° (1/4 turn) further |

| q | Renew |

| 4 - | Drive chain for oil pump |

| q | Mark direction of rotation before removing |

| q | Check for wear |

| 5 - | Sealing flange (pulley end) |

| q | Apply sealant prior to installing → Chapter |

| q | Renewing crankshaft oil seal - pulley end → Chapter |

| 6 - | 15 Nm |

| 7 - | Chain tensioner |

| q | Do not dismantle |

| q | Note installation position |

| q | When installing, pre-tension spring and engage |

| q | Tighten to 16 Nm |

| 8 - | Chain sprocket for oil pump |

| q | Removing and installing → Chapter |

| 9 - | Dowel sleeves |

| q | 2x |

| 10 - | 15 Nm |

| 11 - | Suction pipe |

| q | Clean strainer if dirty |

| 12 - | O-ring |

| q | Renew |

| 13 - | Baffle plate |

| 14 - | 16 Nm |

| 15 - | 15 Nm |

| 16 - | Sump |

| q | Removing and installing → Chapter |

| q | With oil level and oil temperature sender -G266- |

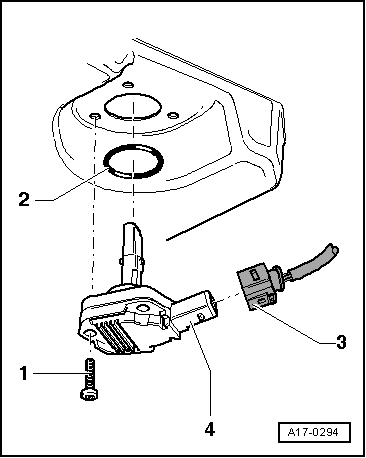

| q | Removing and installing oil level and oil temperature sender -G266- → Fig. |

| 17 - | Seal |

| q | Renew |

| 18 - | Oil drain plug, 30 Nm |

|

|