A3 Mk2

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

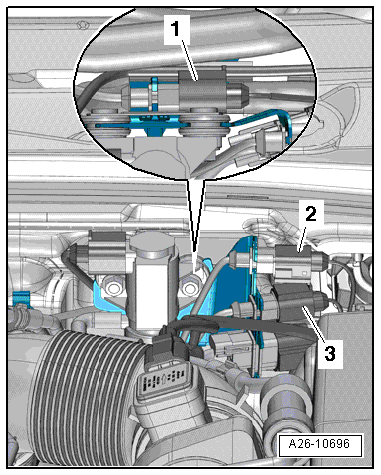

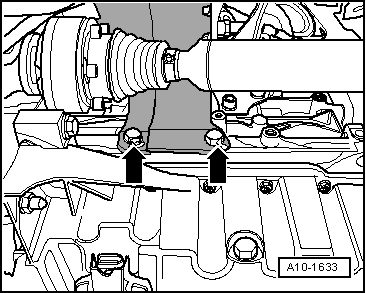

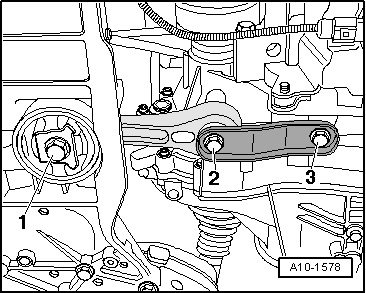

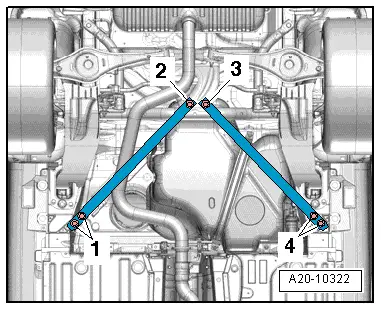

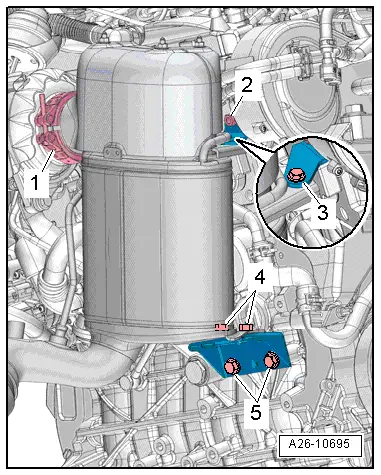

| 1. | Fit particulate filter to turbocharger, attach clip -1- without tightening | |||

| 2. | Fit bolts -2 ... 5- by hand without tightening

| |||

| 3. | Tighten clamp -1- | |||

| 4. | Tighten bolts -2- and -5-. | |||

| 5. | Tighten bolts -3- and -4-. | |||

|

Caution

Caution