| –

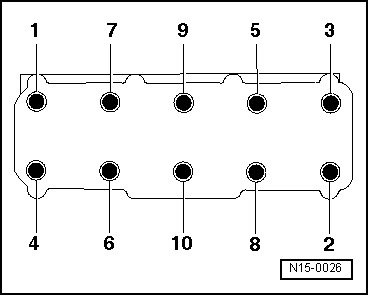

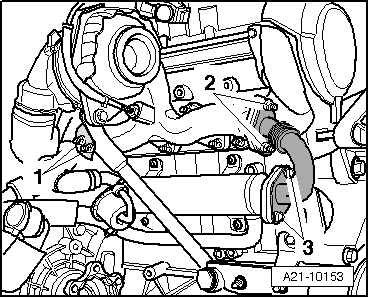

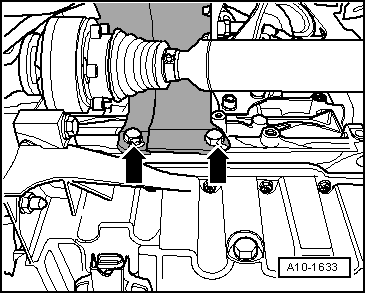

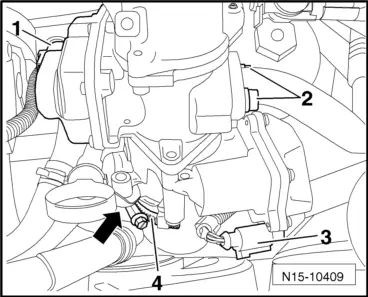

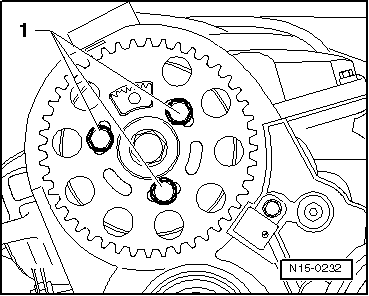

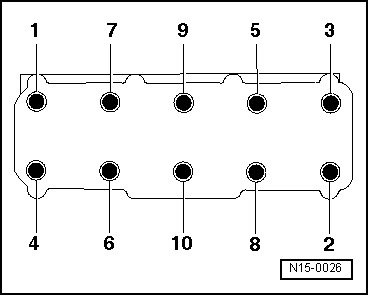

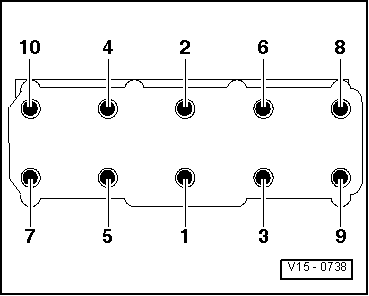

| Slacken cylinder head bolts in the sequence -1 ... 10-. |

Note | A second mechanic is required for removal of the cylinder head. |

| –

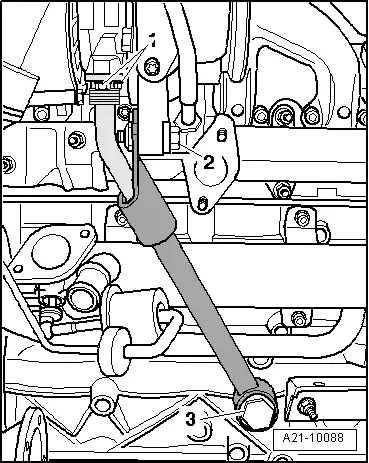

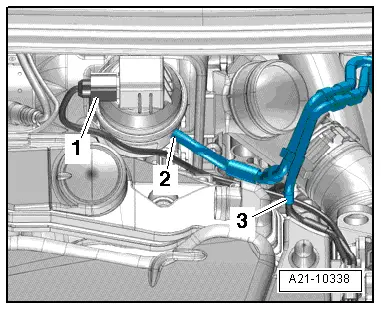

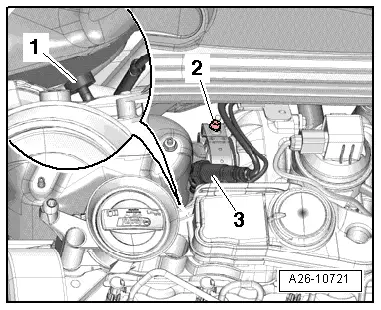

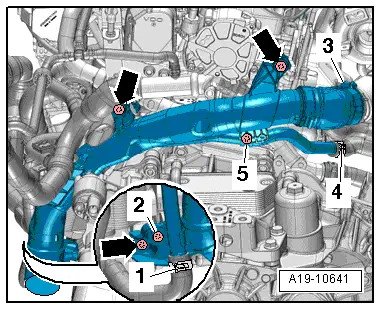

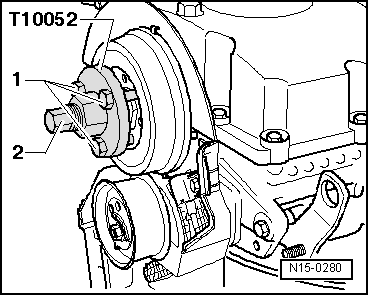

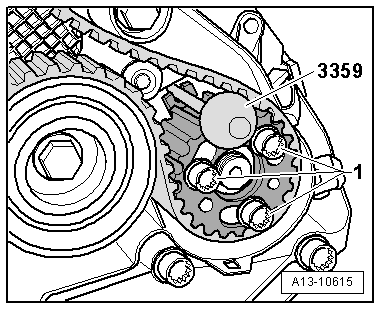

| Swivel cylinder head to left and out of rear toothed belt cover and detach tensioning roller at the same time. |

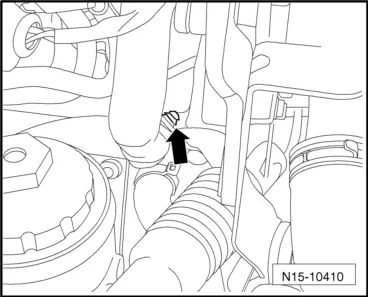

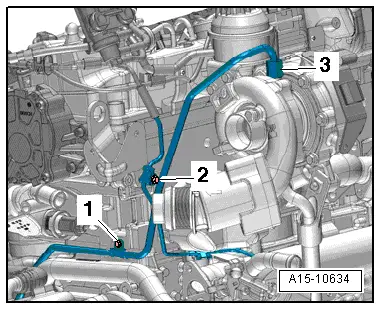

| –

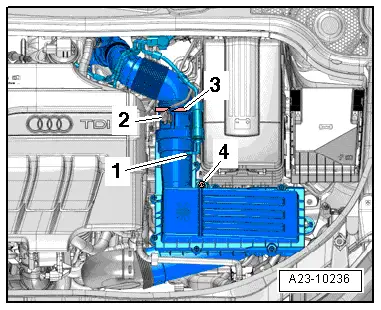

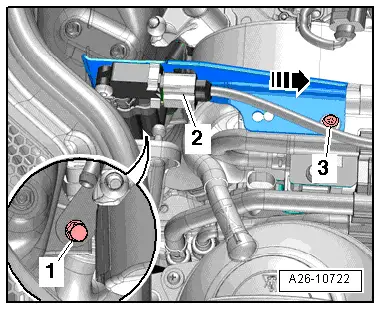

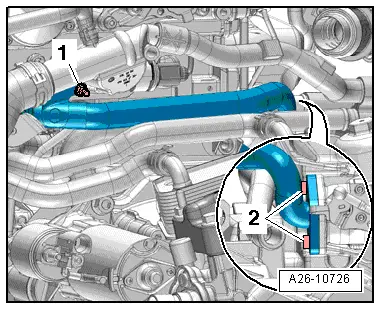

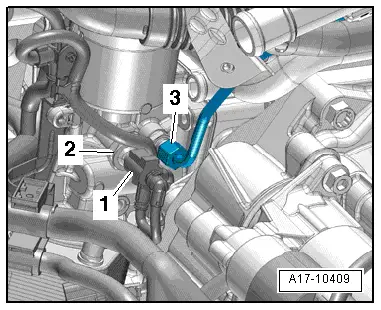

| Take care not to damage oil return line for turbocharger. |

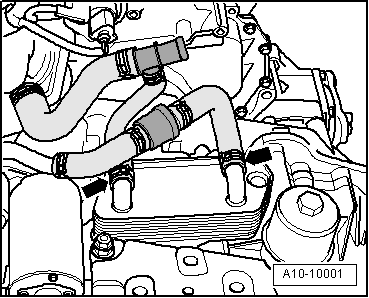

| –

| Take care to place cylinder head down without bending oil return line. If necessary, place a block of wood below exhaust manifold. |

Caution | Risk of damage to glow plugs when putting down cylinder head. |

| After removal, the cylinder head must not be put down on the gasket side with the glow plugs still installed, because the glow plugs project slightly beyond the gasket surface. |

|

Note | Audi A3 models with a 2.0 ltr. 4-valve TDI engine (common rail) are always equipped with steel glow plugs. |

Caution | Avoid damage to sealing surfaces. |

| t

| Carefully remove sealant residue from cylinder head and cylinder block. |

| t

| Ensure that no long scores or scratches are made on the surfaces. |

| Avoid damage to cylinder block. |

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

| Risk of leaks at cylinder head gasket. |

| t

| Carefully remove any sealant residue from the cylinder head and cylinder block. Ensure that no long scores or scratches are made on the surfaces. |

| t

| Carefully remove any remaining emery and abrasive material. |

| t

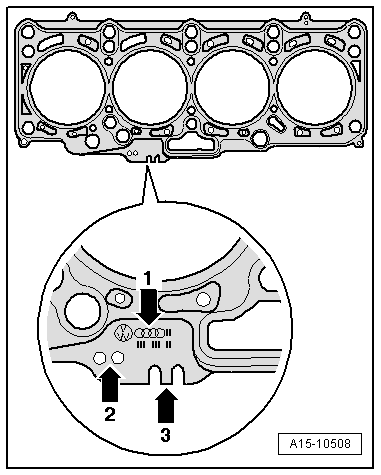

| Do not remove new cylinder head gasket from packaging until it is ready to be fitted. |

| t

| Handle the cylinder head gasket very carefully to prevent damage to the silicone coating or the indented area of the gasket. |

| Avoid damage to open valves. |

| When installing an exchange cylinder head, the plastic protectors fitted to protect the open valves should not be removed until the cylinder head is ready to be fitted. |

| Avoid damage to valves and piston crowns after working on valve gear. |

| Turn the crankshaft carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

Note | t

| Renew the bolts tightened with specified tightening angle. |

| t

| Renew self-locking nuts as well as seals, gaskets and O-rings. |

| t

| Cylinder heads must not be reworked on TDI engines. |

| t

| When installing an exchange cylinder head, the contact surfaces between roller rocker fingers and cams must be oiled. |

| t

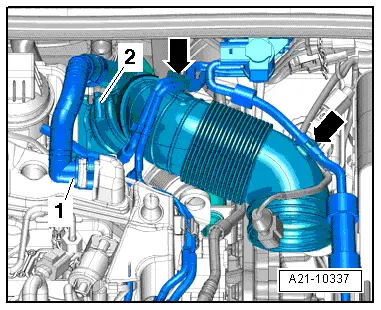

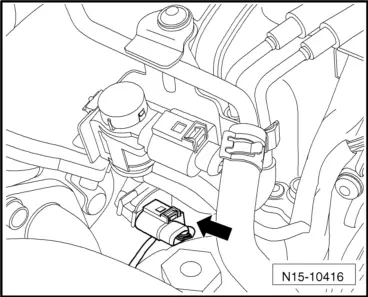

| Hose connections and air pipes and hoses must be free of oil and grease before assembly. |

| t

| To ensure that the air hoses can be properly secured at their connections, spray rust remover onto the worm thread of used hose clips before installing. |

| t

| After fitting a new cylinder head or cylinder head gasket, change the engine oil and the coolant in the entire cooling system. |

| –

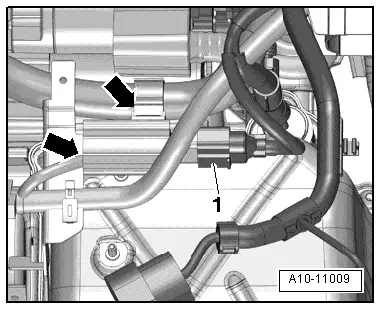

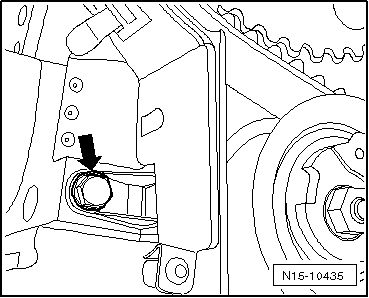

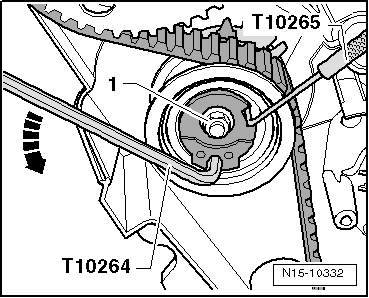

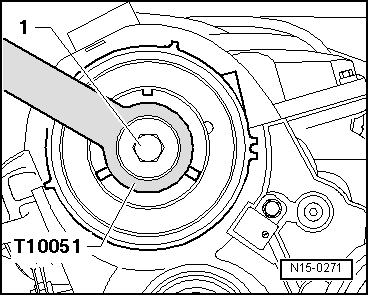

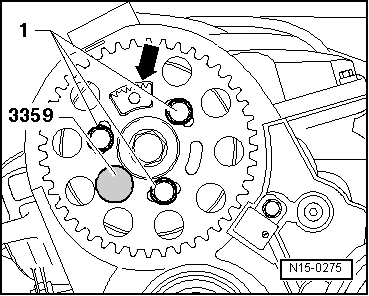

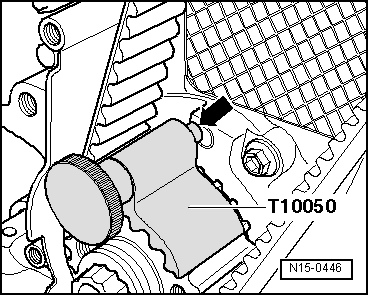

| Before fitting cylinder head, remove crankshaft stop -T10050- and turn crankshaft against normal direction of rotation until all pistons are positioned approximately equally below „TDC“. |

| –

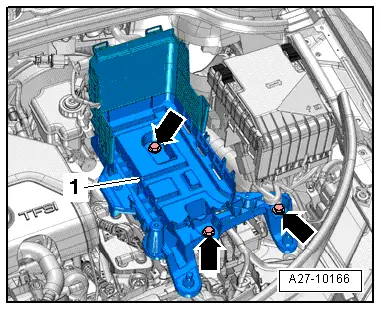

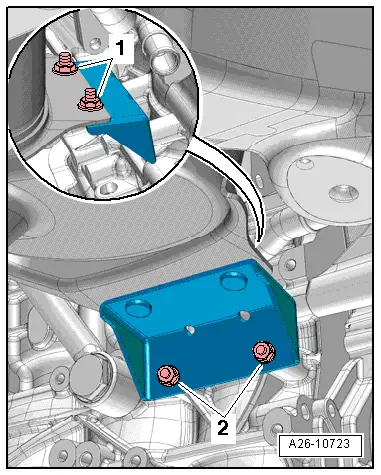

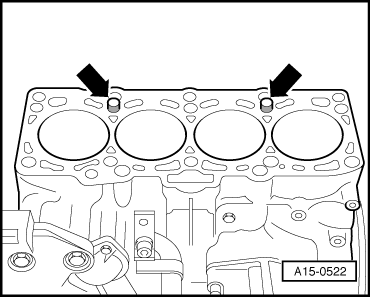

| If not already fitted, install dowel sleeves in cylinder block for centring cylinder block and cylinder head. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution