| –

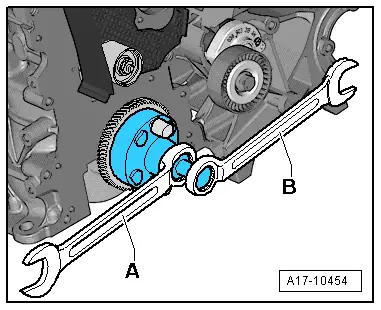

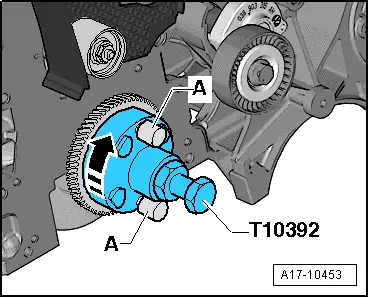

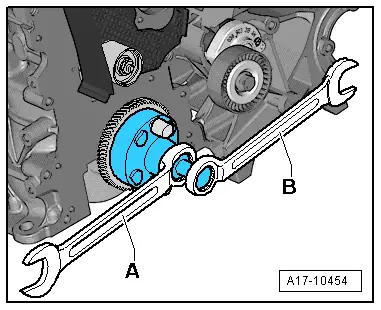

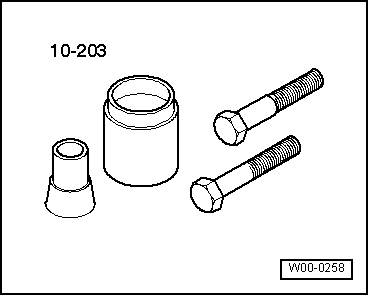

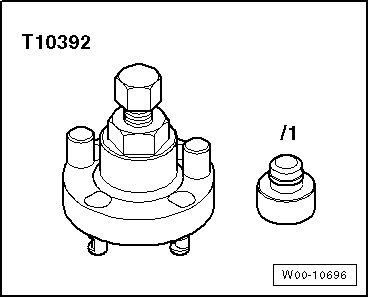

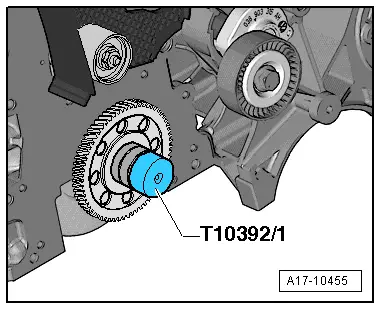

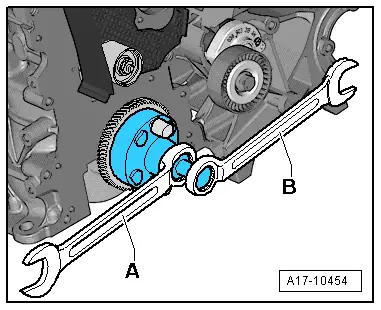

| Counterhold crankshaft with ring spanner -A- and pull spur gear off end of crankshaft by screwing in spindle with ring spanner -B-. |

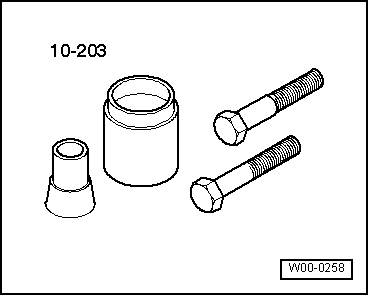

Note | t

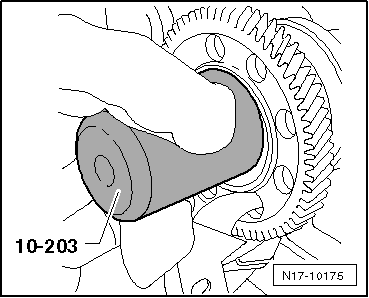

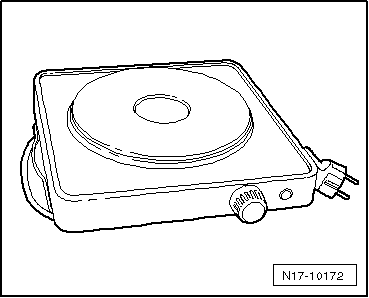

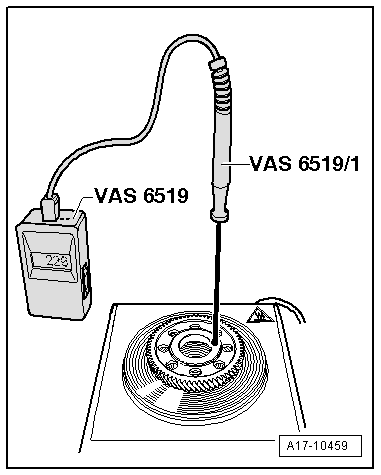

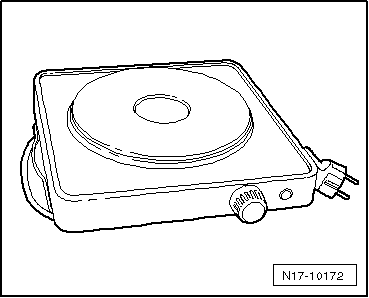

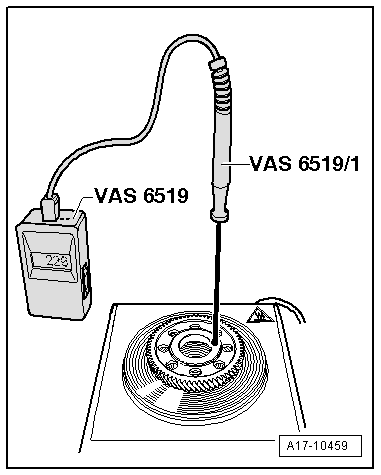

| While heating up the new spur gear, monitor the temperature with the temperature gauge -VAS 6519-. |

| t

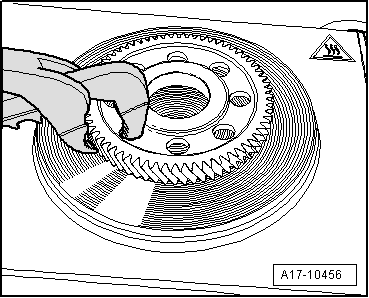

| When the temperature reaches 200 °C, you have approx. 4 seconds to fit the spur gear on the crankshaft. |

| t

| A higher temperature increases the amount of time available (220 °C = approx. 6 seconds). |

| t

| Make sure the end of the crankshaft is clean. |

Caution | Do not exceed a maximum temperature of 240 °C; otherwise the spur gear can become discoloured and distorted. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note