A3 Mk2

| Component | Nm | ||

| Bolts/nuts | M6 | 10 | |

| M7 | 15 | ||

| M8 | 20 | ||

| M10 | 40 | ||

| M12 | 65 | ||

| Except for the following: | |||

| Underbody cross member (front) to body | 23 | ||

|

|

|

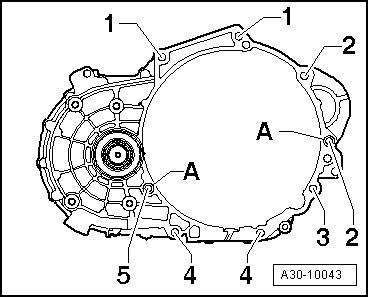

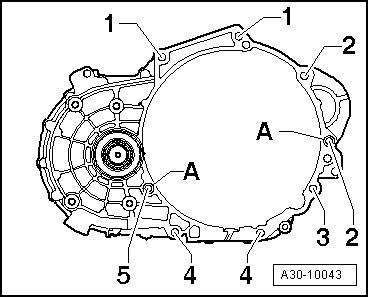

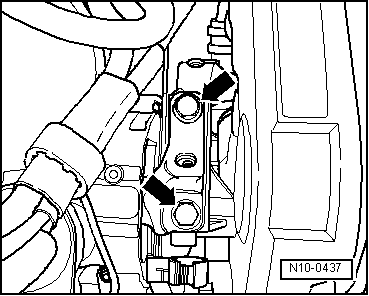

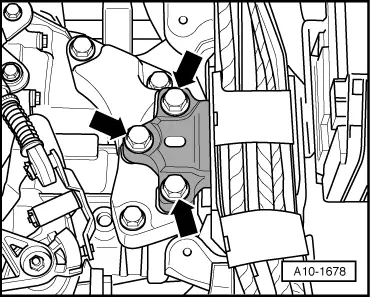

| Item | Bolt | Nm | ||||

| 1 1) | M12x55 | 80 | ||||

| 2 1) | M12x165 | 80 | ||||

| 3 | M10x105 | 40 | ||||

| 4 | M10x50 | 40 | ||||

| 5 2) | M12x65 | 80 | ||||

| A | Dowel sleeves for centralising | |||||

| ||||||

|

|

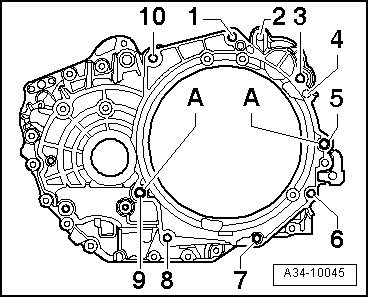

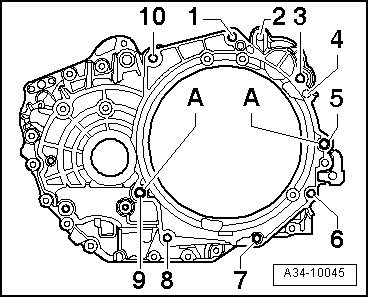

| Item | Bolt | Nm |

| 1, 3, 10 | M12x55 | 80 |

| 5 | M12x65 | 80 |

| 6, 7, 8 | M10x50 | 40 |

| 9 | M12x70 | 80 |

| 2, 4 | Securing starter → Electrical system; Rep. gr.27 | |

| A | Dowel sleeves for centralising | |

Note

Note

Note

Note

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

Caution

Caution