A3 Mk2

Note

Note

|

|

|

|

|

Note

Note

|

|

|

|

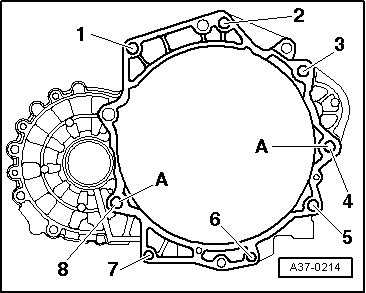

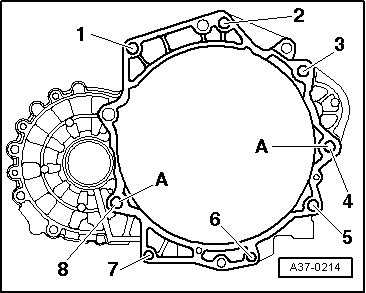

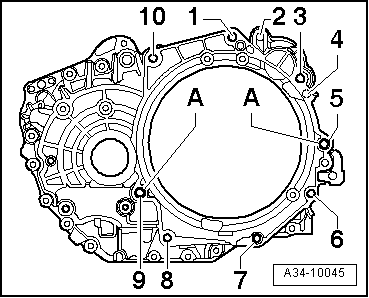

| Item | Bolt | Nm | ||||

| 1, 2 | M12x55 1)2) | 80 | ||||

| 3, 4 | M12x165 1) | 80 | ||||

| 5 | M12x105 2) | 80 | ||||

| 6, 7 | M10x50 2) | 40 | ||||

| 8 | M10x70 2) | 40 | ||||

| A | Dowel sleeves for centralising | |||||

| ||||||

|

|

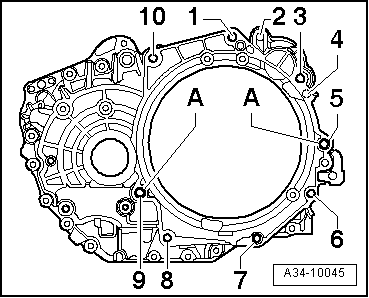

| Item | Bolt | Nm | ||

| 1, 3, 10 | M12x55 | 80 | ||

| 5, 9 | M12x70 | 80 | ||

| 6, 7, 8 | M10x50 | 40 | ||

| A | Dowel sleeves for centralising | |||

| ||||

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

| Component | Nm | ||

| Bolts/nuts | M6 | 10 | |

| M7 | 15 | ||

| M8 | 20 | ||

| M10 | 40 | ||

| M12 | 65 | ||

| Except for the following: | |||

| Starter to dual-clutch gearbox | 40 | ||

| Underbody cross member to body | 23 | ||

| Charge pressure solenoid valve -N75- to bracket | 8 | ||

| Terminal B+ to starter | 16 | ||

| Earth cable | 22 | ||

| Oil pressure switch to oil filter bracket | 20 | ||

| Air pipe (left-side) to bracket | 8 | ||

| Air cleaner housing to bracket | 10 | ||

| Air pipe (right-side) to bracket | 8 | ||

| Heat shield to cylinder block | 35 | ||

Caution

Caution