A3 Mk2

Note

Note |

|

|

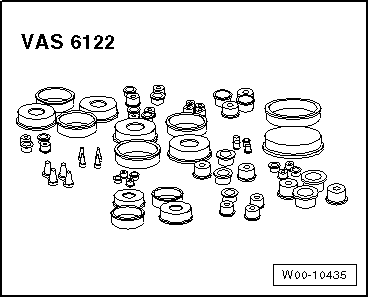

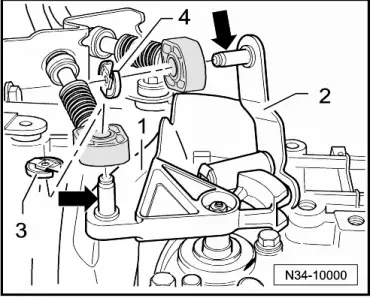

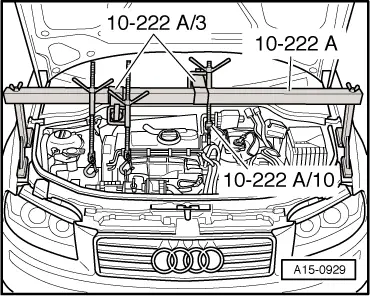

| Special tools and workshop equipment required |

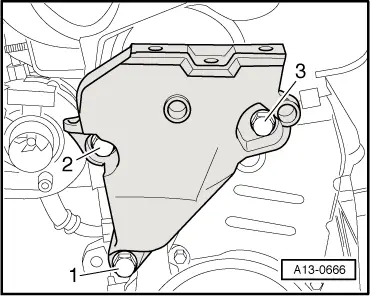

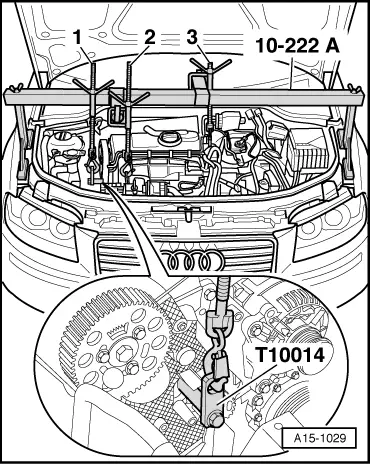

| t | Support bracket -10 - 222 A- |

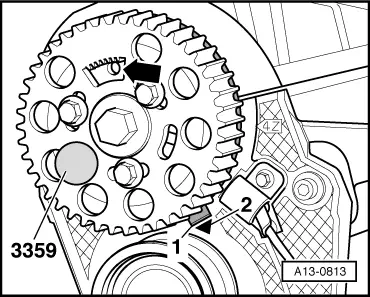

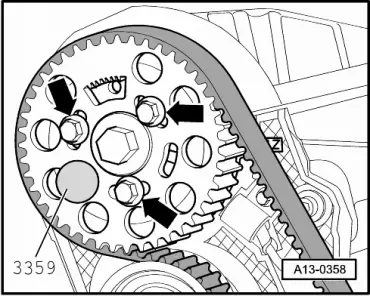

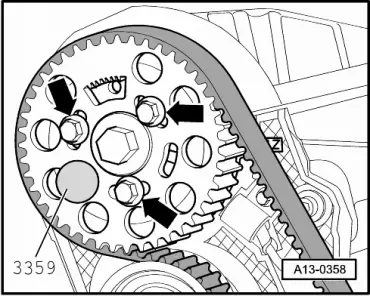

| t | Diesel injection pump locking pin -3359- |

| t | Drip tray for workshop hoist -VAS 6208- |

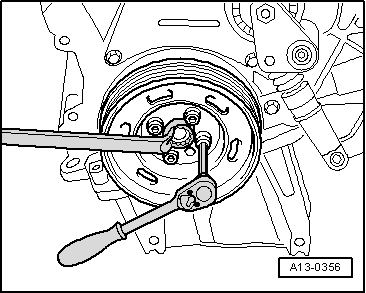

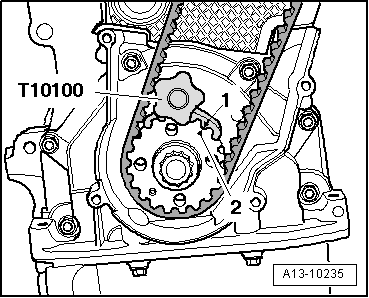

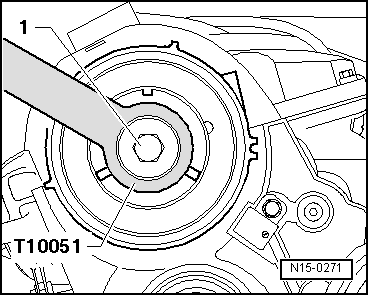

| t | Counterhold tool -T10051- |

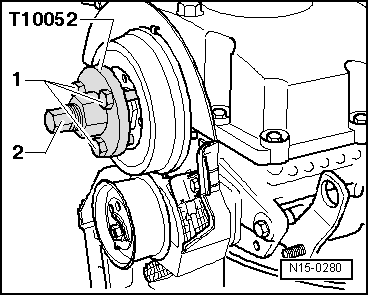

| t | Puller -T10052- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution WARNING

WARNING