| –

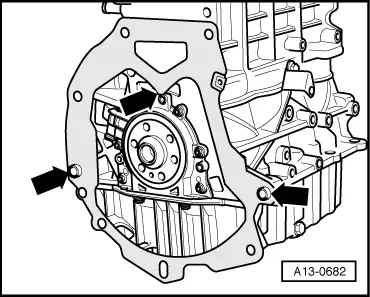

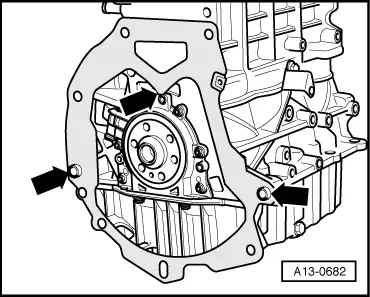

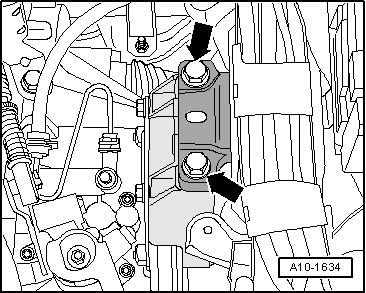

| Ensure that the intermediate plate is engaged on the sealing flange and pushed onto the dowel sleeves -arrows-. |

| –

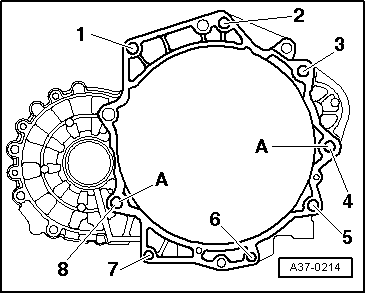

| Check that clutch plate is correctly centred → Rep. Gr.30. |

| –

| Check clutch release bearing for wear, renew if necessary. |

| –

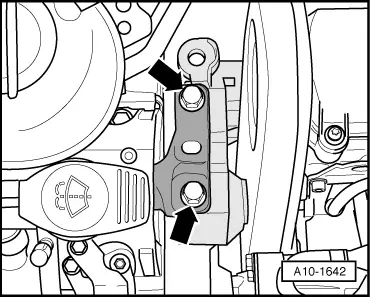

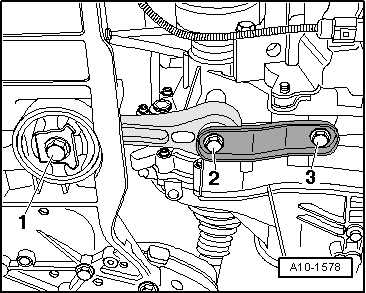

| Bolt gearbox to engine. |

Note | t

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricants such as engine or gearbox oil may be used, but do not use lubricants containing graphite. |

| t

| Do not use degreased parts. |

| t

| Tolerance for tightening torques ± 15 %. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution