A3 Mk2

Note

Note |

|

|

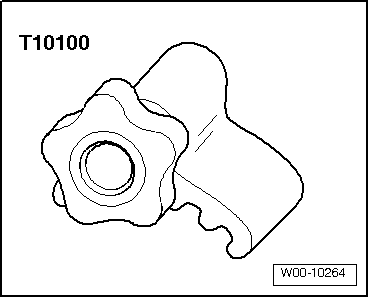

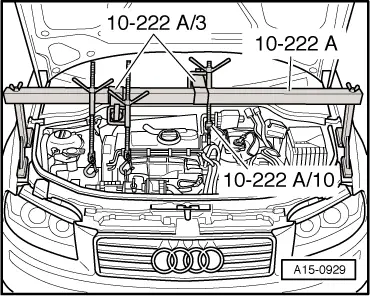

| Special tools and workshop equipment required |

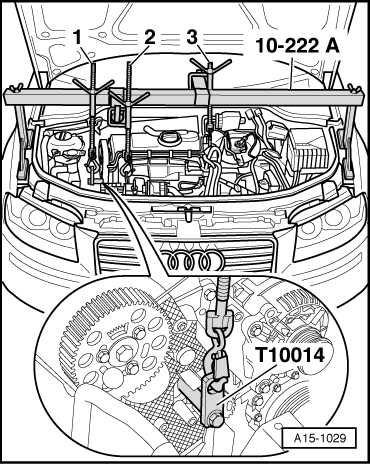

| t | Support bracket -10-222 A- |

| t | Drip tray for workshop hoist -VAS 6208- or -V.A.G 1306- |

| t | Hose clip pliers -VAS 6340- or -VAS 5024 A- |

| t | Retainer -T10014- |

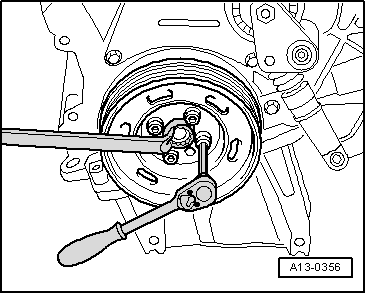

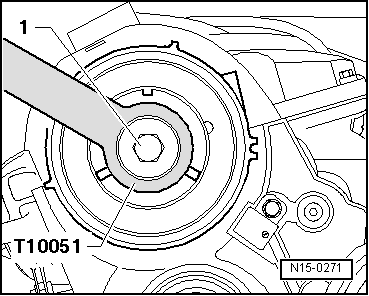

| t | Counterhold tool -T10051- |

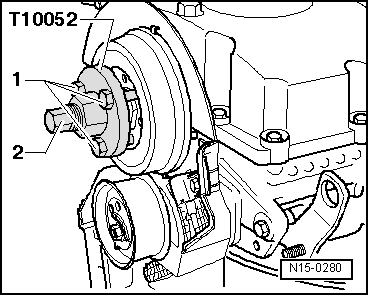

| t | Puller -T10052- |

| t | Hook (with spindle) -10-222 A/10- |

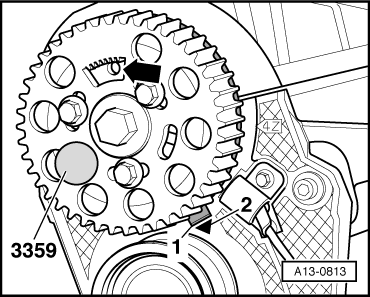

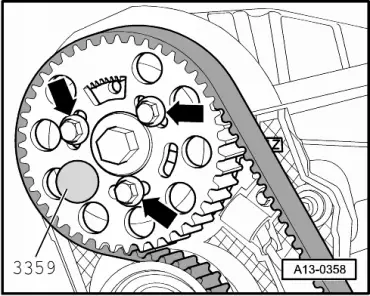

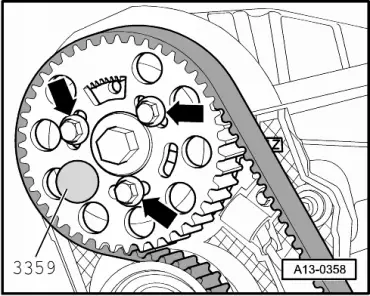

| t | Diesel injection pump locking pin -3359- |

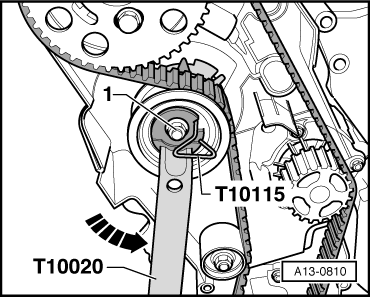

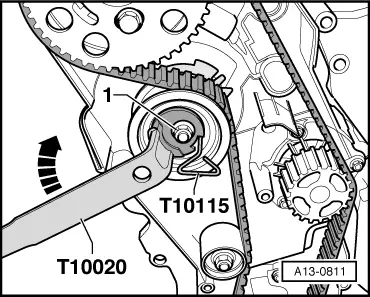

| t | Pin wrench -T10020- |

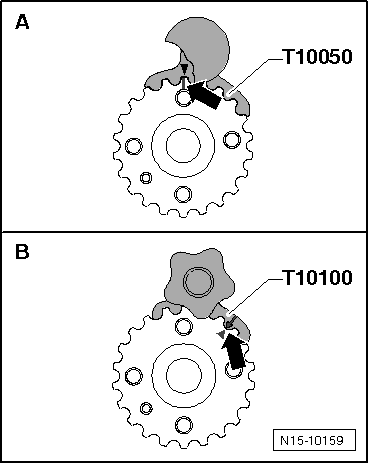

| t | Crankshaft stop -T10050- for engines with circular crankshaft sprocket |

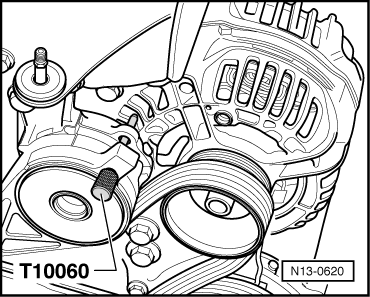

| t | Locking pin -T10060 A- or -T10060- |

| t | Locking pin -T10115- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution WARNING

WARNING