| –

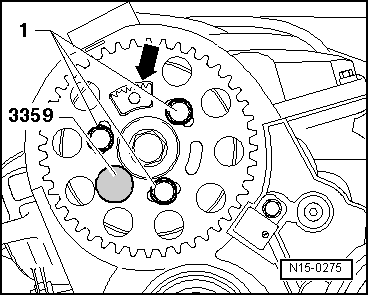

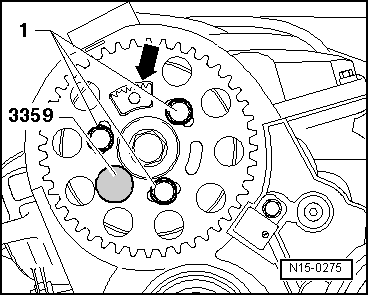

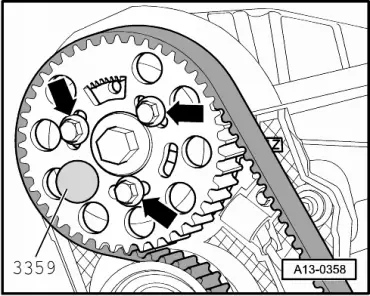

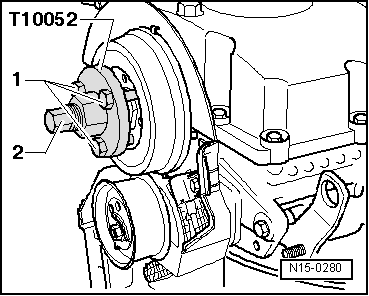

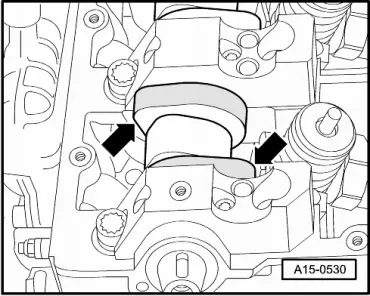

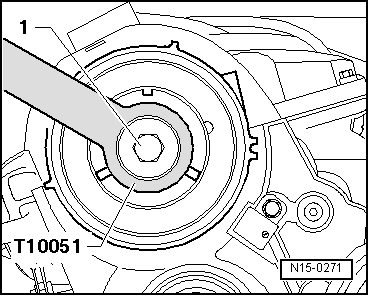

| Push camshaft sprocket onto hub. |

| l

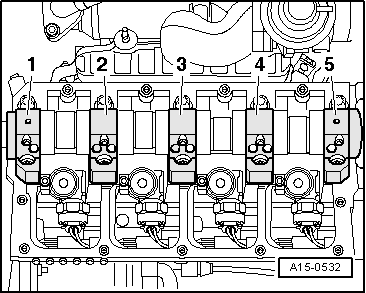

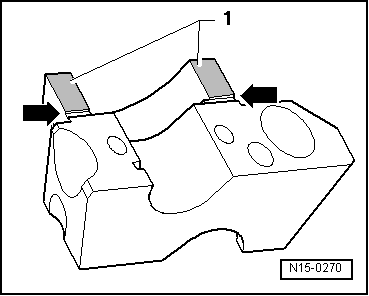

| Toothed segment -arrow- in camshaft sprocket must face upwards. |

| –

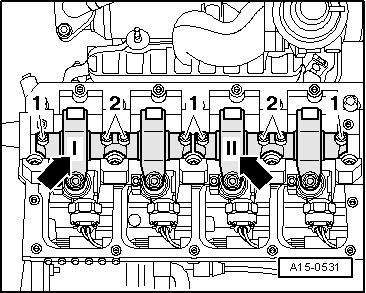

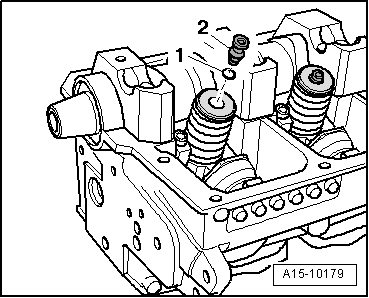

| Screw in bolts -1- finger-tight. |

| –

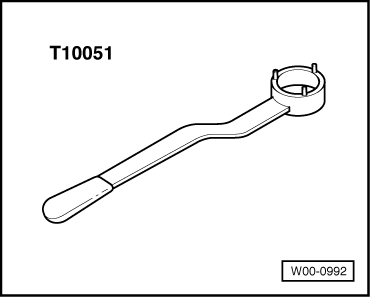

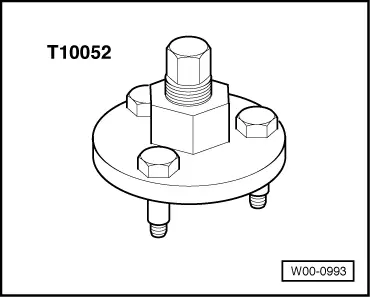

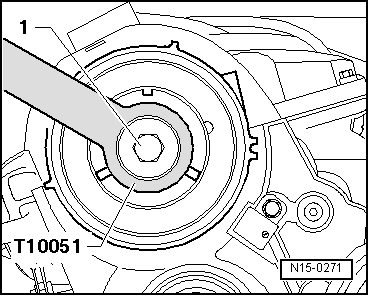

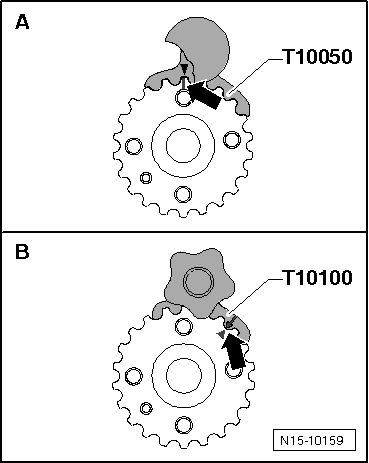

| Lock hub on camshaft with locking pin -3359-. |

| –

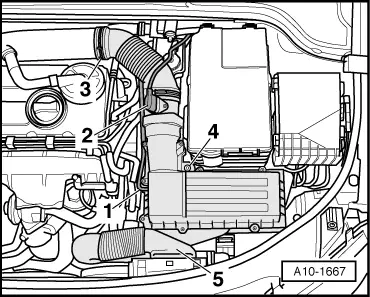

| Fit toothed belt (adjust valve timing): |

| t

| Vehicles up to approx. 05.2005 → Anchor |

| t

| Vehicles from approx. 06.2005 → Anchor |

| –

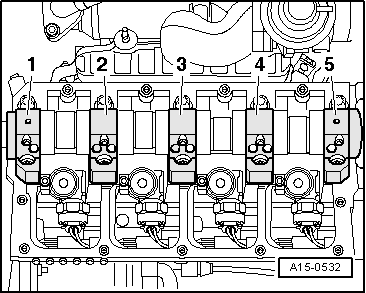

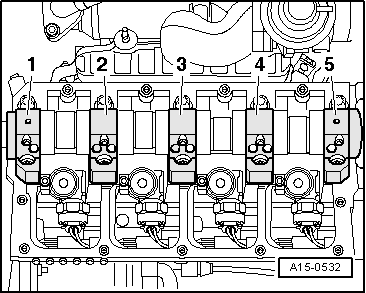

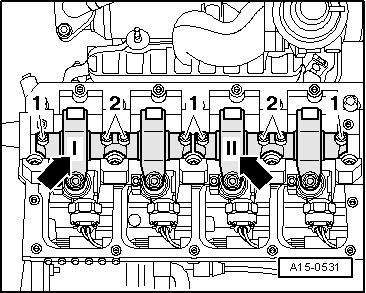

| If the rocker arm shafts or ball studs and adjuster screws were renewed, the unit injectors must be adjusted → Rep. Gr.23. |

Note | t

| After installing the camshaft, the engine must NOT be started for about 30 minutes. The hydraulic tappets have to settle (otherwise valves will strike pistons). |

| t

| After working on the valve gear, turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note