A3 Mk2

| Toothed belt drive - exploded view of components |

| 1 - | 10 Nm + 90° (1/4 turn) further |

| q | Renew |

| 2 - | Vibration damper |

| q | With pulley for poly V-belt |

| q | Removing and installing → Chapter |

| 3 - | Toothed belt cover (bottom) |

| 4 - | 10 Nm |

| q | Install using locking fluid; for locking fluid refer to → Parts catalogue |

| 5 - | Toothed belt cover (centre) |

| q | To remove, take out top toothed belt cover and unbolt poly V-belt tensioner |

| 6 - | Toothed belt cover (top) |

| q | To remove, take out air pipe (right-side) |

| q | Engage carefully in centre toothed belt cover when installing |

| 7 - | Toothed belt |

| q | Before removing, mark direction of rotation with chalk or felt-tipped pen. If the belt runs in the opposite direction when it is refitted, this can cause breakage. |

| q | Check for wear |

| Vehicles up to approx. 05.2005 |

| q | Removing → Chapter |

| q | Installing (adjusting valve timing) → Anchor |

| Vehicles from approx. 06.2005 |

| q | Removing → Chapter |

| q | Installing (adjusting valve timing) → Anchor |

| 8 - | 20 Nm + 45° (1/8 turn) further |

| 9 - | Tensioning roller |

| 10 - | 25 Nm |

| 11 - | Camshaft sprocket |

| q | Mark installation position |

| 12 - | 100 Nm |

| q | Use counterhold tool -T10051- when loosening and tightening → Chapter „Removing and installing camshaft“ |

| 13 - | Hub |

| q | With sender wheel for Hall sender -G40- |

| q | Use counterhold tool -T10051- when loosening and tightening |

| q | To remove, use puller -T10052- |

| q | Pulling off: Vehicles up to approx. 05.2005 → Anchor, vehicles from approx. 06.2005 → Anchor |

| 14 - | 10 Nm |

| q | Install using locking fluid; for locking fluid refer to → Parts catalogue |

| 15 - | Toothed belt cover (rear) |

| q | To remove, take out coolant pump → Chapter |

| q | When installing, engage carefully in sealing flange at pulley end. |

| 16 - | Rubber grommet |

| q | Renew if damaged |

| 17 - | 25 Nm |

| 18 - | O-ring |

| q | Renew |

| 19 - | Coolant pump |

| q | Removing and installing → Chapter |

| 20 - | 13 Nm |

| 21 - | Idler roller |

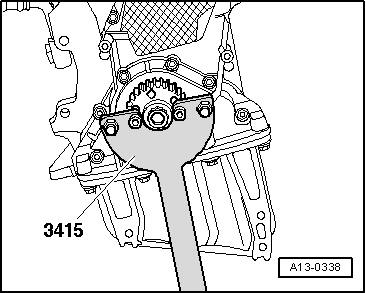

| 22 - | Crankshaft sprocket |

| q | Contact surface between sprocket and crankshaft must be free of oil |

| q | Can only be installed in one position |

| q | Removing and installing → Fig. |

| 23 - | 120 Nm + 90° (1/4 turn) further |

| q | Renew |

| q | Do not lubricate with oil |

| q | Use counterhold tool -3415- when loosening and tightening → Fig. |

| 24 - | 22 Nm |

| 25 - | 10 Nm |

| q | Install using locking fluid; for locking fluid refer to → Parts catalogue |

|

|