A3 Mk2

Note

Note |

|

|

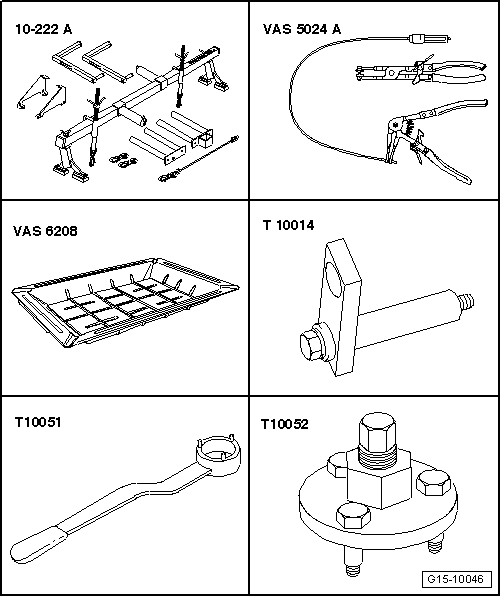

| Special tools and workshop equipment required |

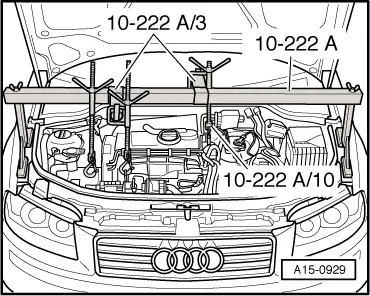

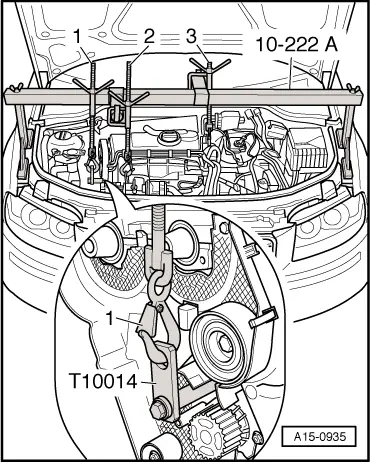

| t | Support bracket -10 - 222 A- |

| t | Spring type clip pliers -VAS 5024 A- |

| t | Drip tray for workshop hoist -VAS 6208- |

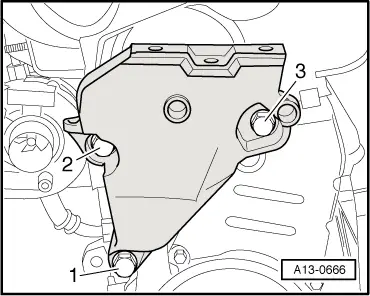

| t | Retainer -T10014- |

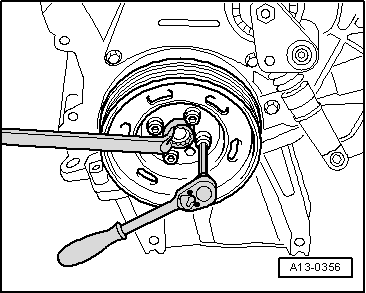

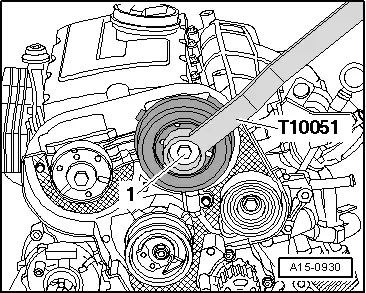

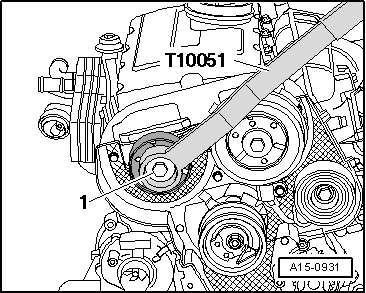

| t | Counterhold tool -T10051- |

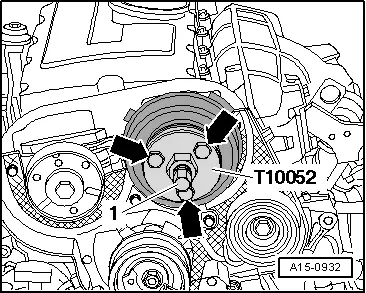

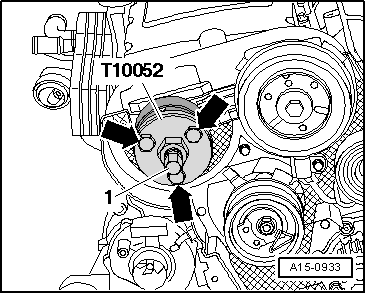

| t | Puller -T10052- |

| t | Hooks -10 - 222 A /10- (with spindle) |

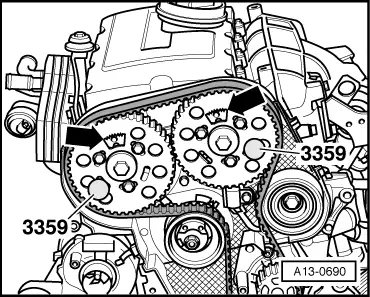

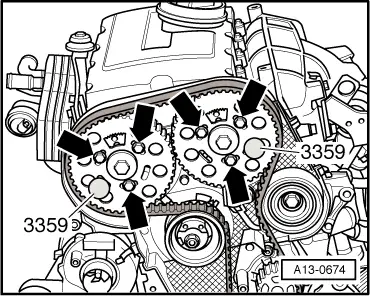

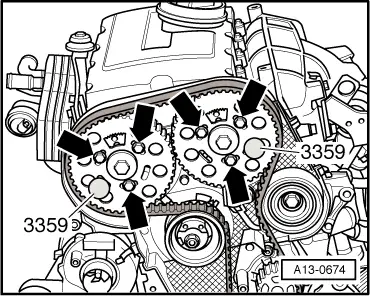

| t | Diesel injection pump locking pin -3359- (2x) |

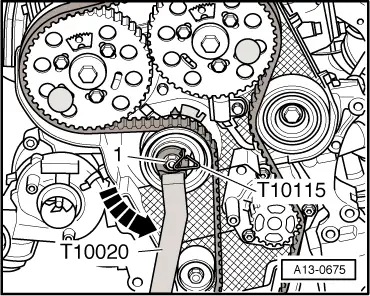

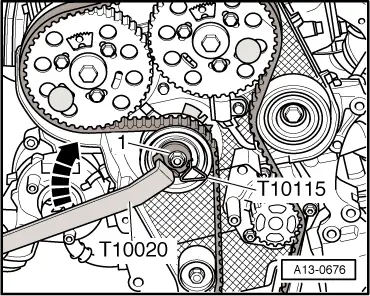

| t | Pin wrench -T10020- |

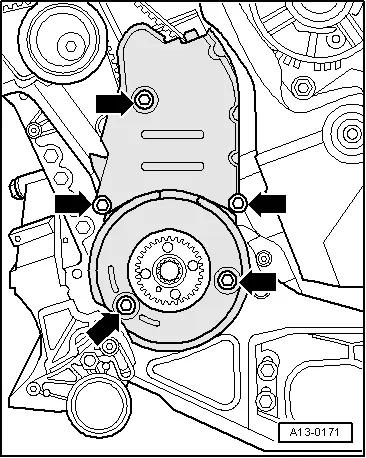

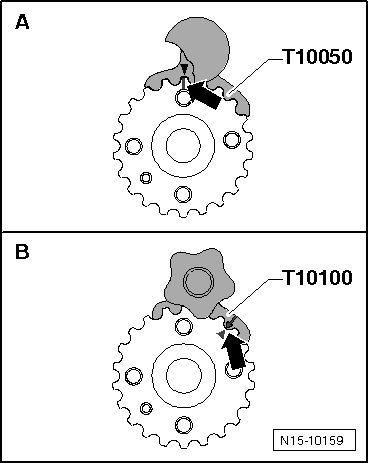

| t | Crankshaft stop -T10050- for engines with circular crankshaft sprocket |

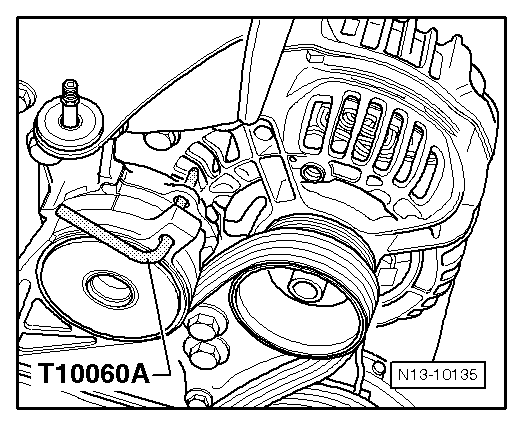

| t | Locking pin -T10060 A- |

| t | Crankshaft stop -T10100- for engines with oval crankshaft sprocket |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Caution

Caution WARNING

WARNING