| –

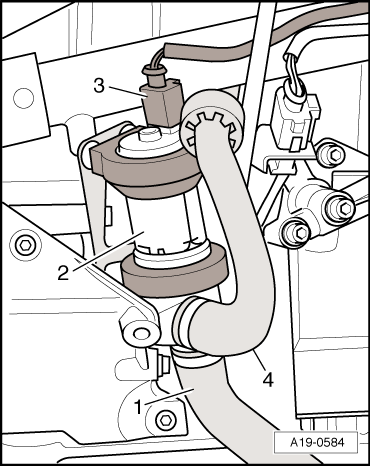

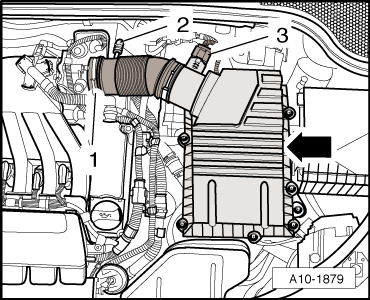

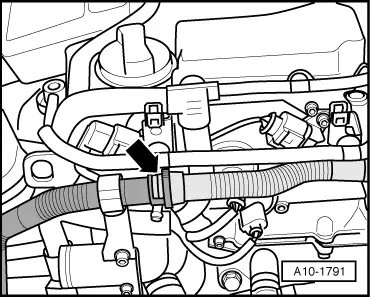

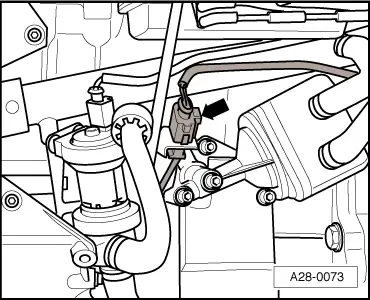

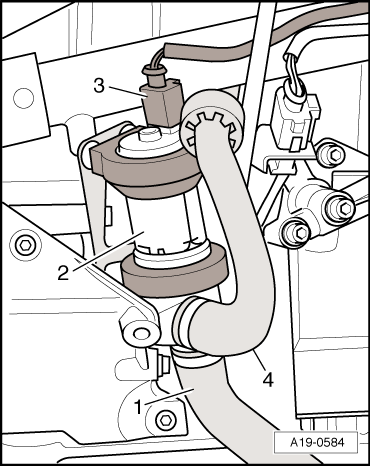

| Unplug electrical connector -3- at continued circulation coolant pump -V51--Item 2-. |

| –

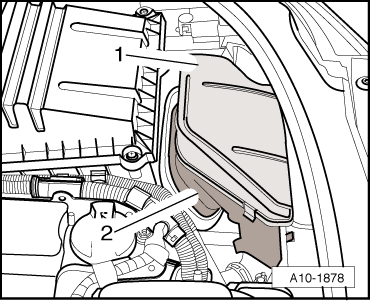

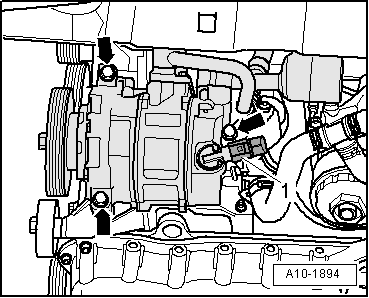

| Pull the pump downwards out of the rubber retainers on bracket. If necessary, spray rubber retainers with silicone-free lubricant. |

| –

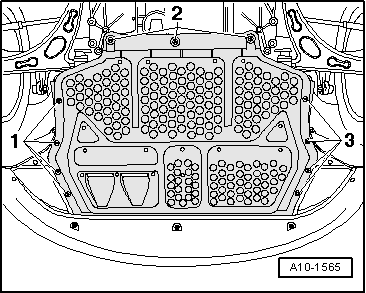

| Unscrew bracket for continued circulation coolant pump -V51-. |

| –

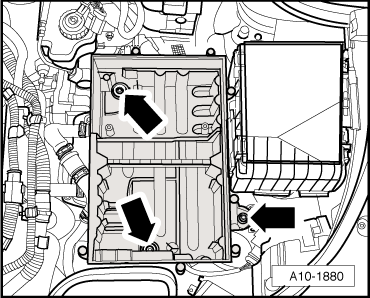

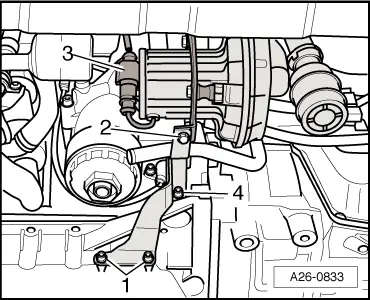

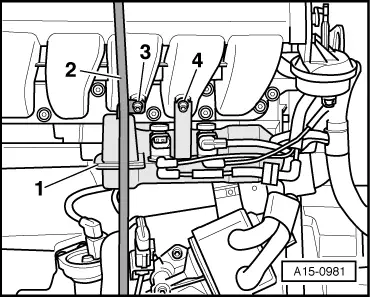

| Unclip bracket for wiring harness (right-side) from coolant pipe. |

| –

| Disconnect wiring harness (left-side) from bracket at coolant pipe. |

| –

| Disconnect coolant hose to oil cooler at coolant pipe. |

| –

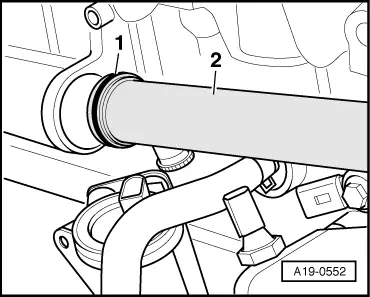

| Pull coolant pipe out of cylinder block. |

| Installation is carried out in the reverse order; note the following: |

Note | –

| Before installing, clean and smoothen sealing surface for O-ring in cylinder block. |

|

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING