| –

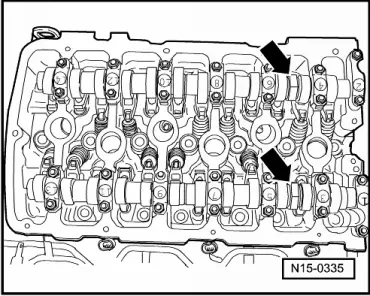

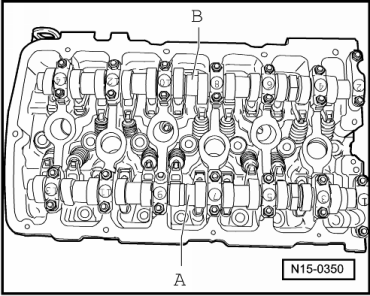

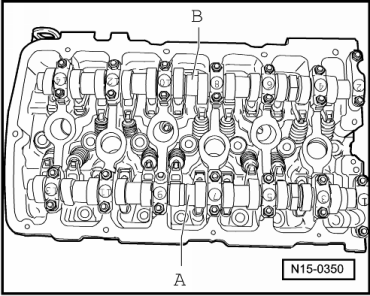

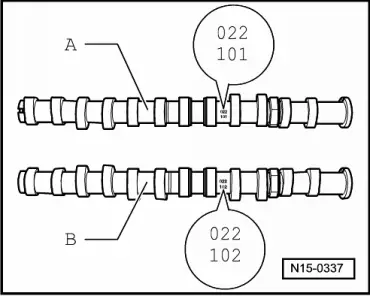

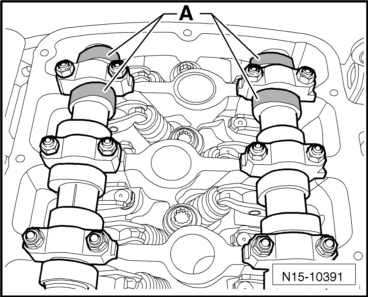

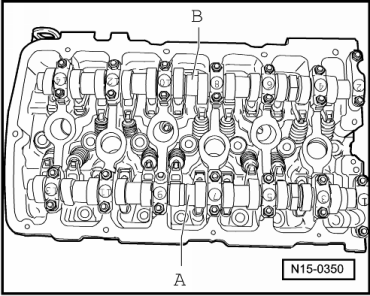

| Remove the inlet camshaft -A- as follows: |

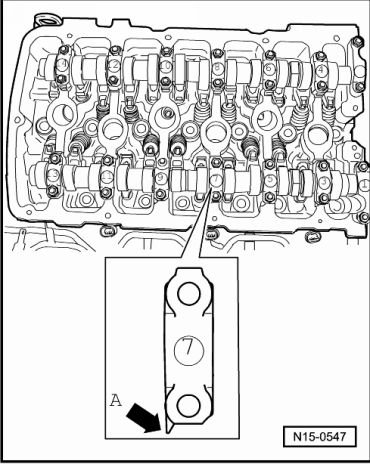

| 1 - | Unbolt bearing caps 1 and 13. |

| 2 - | Unbolt bearing caps 3 and 11. |

| 3 - | Unbolt bearing cap 7. |

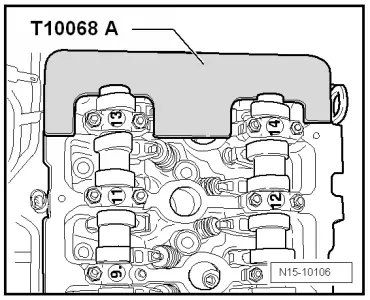

| 4 - | Loosen bearing caps 5 and 9 alternately in a diagonal sequence and remove. |

| –

| Remove the exhaust camshaft -B- as follows: |

| 1 - | Unbolt bearing caps 2 and 14. |

| 2 - | Unbolt bearing caps 4 and 12. |

| 3 - | Unbolt bearing cap 8. |

| 4 - | Loosen bearing caps 6 and 10 alternately in a diagonal sequence and remove. |

| –

| Carefully remove the camshafts and place them down on a clean surface. |

Note | t

| The crankshaft must not be at TDC at any cylinder when the camshafts are installed. Otherwise, there is a risk of damage to valves and piston crowns. |

| t

| After installing camshafts, wait for approx. 30 minutes before starting engine. Hydraulic valve compensation elements have to settle (otherwise valves will strike pistons). |

| t

| After working on the valve gear, turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

|

|

Note

Note

Note

Note

Note

Note