| t

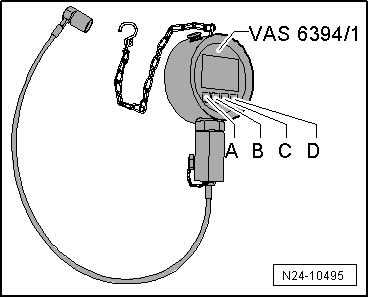

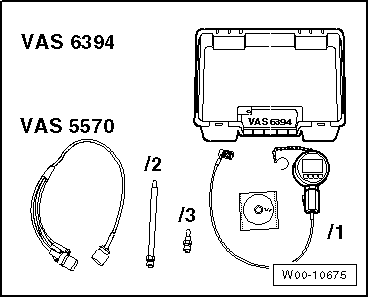

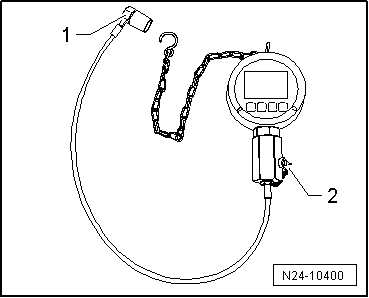

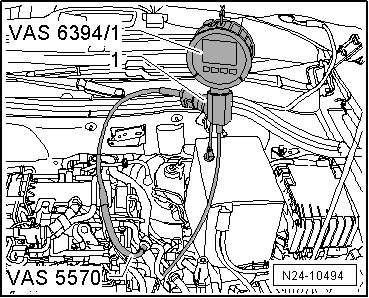

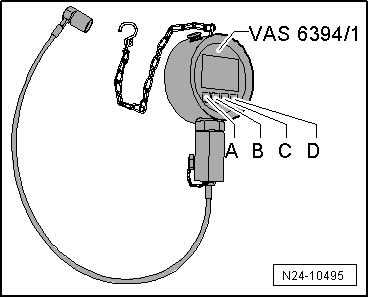

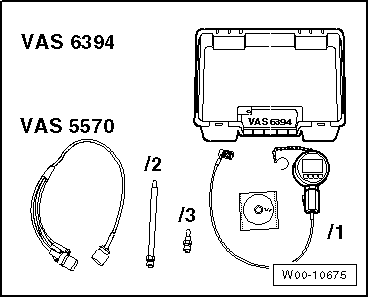

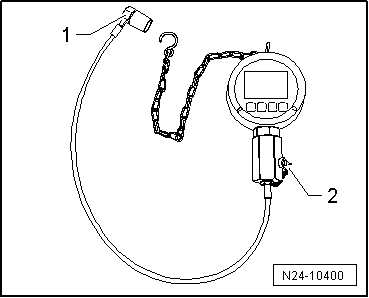

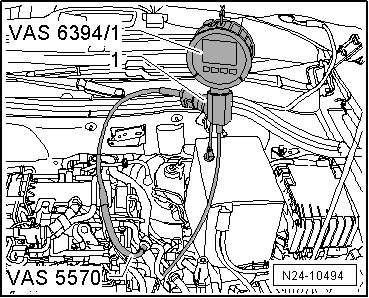

| Pressure sensor tester -VAS 6394- |

| t

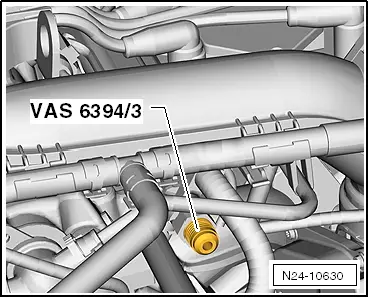

| Socket, 27 mm, long (commercially available) |

| t

| Test instrument adapter -VAS 5570- |

WARNING | The injection system consists of a high-pressure section (maximum approx. 120 bar) and a low-pressure section (approx. 6 bar). |

| Prior to opening the high-pressure section, the fuel pressure in the high-pressure section must be reduced in a controlled manner to a residual pressure of approx. 6 bar. The procedure is described in → Chapter, Reducing fuel pressure in high-pressure section of fuel system. |

|

| –

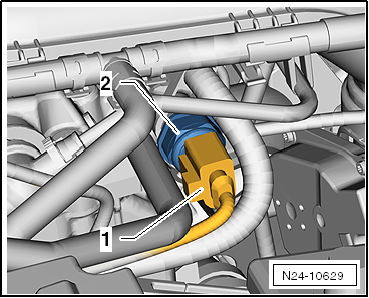

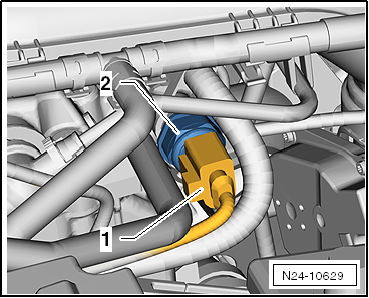

| Unplug connector -1- and remove fuel pressure sender -G247--2-. |

|

|

|

Note

Note

Note

Note