A3 Mk2

|

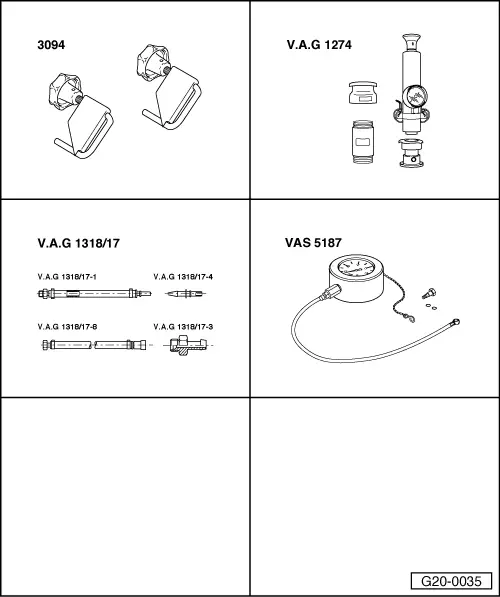

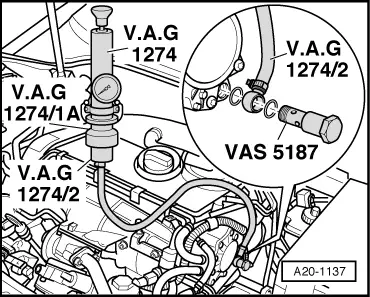

| Special tools and workshop equipment required |

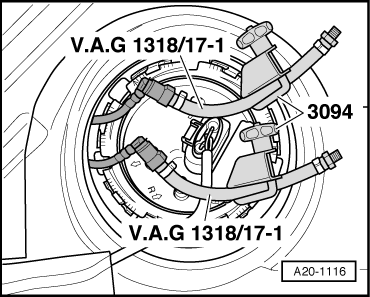

| t | Hose clamps for hoses up to 25 mm -3094- |

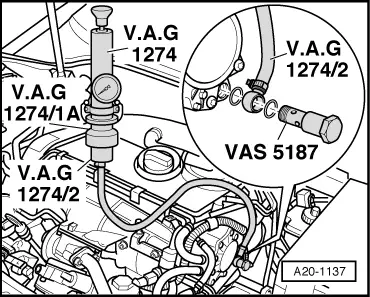

| t | Cooling system tester -V.A.G 1274- with adapter -V.A.G 1274/1A- and adapter for testing diesel fuel -V.A.G 1274/2- |

| t | Adapter -V.A.G 1318/17-1- from adapter set -V.A.G 1318/17- (2 x) |

| t | Banjo bolt -VAS 5187/1A- from tandem pump tester -VAS 5187- |

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

WARNING

WARNING