| –

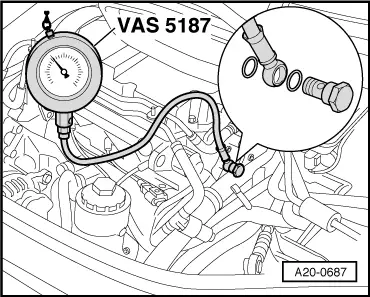

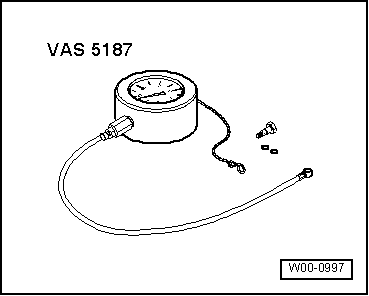

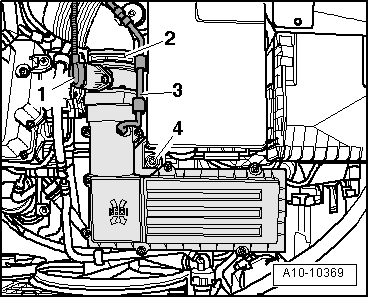

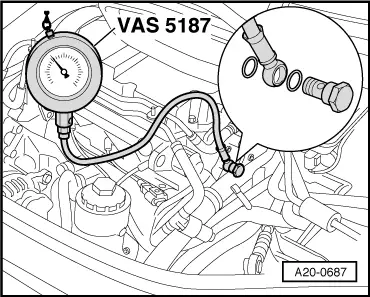

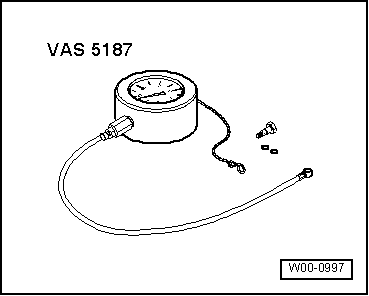

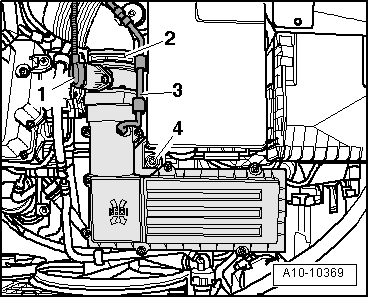

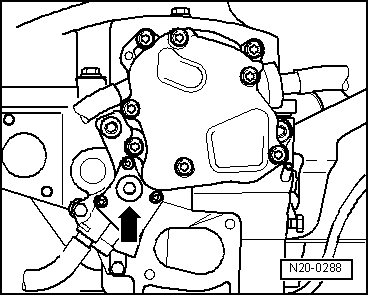

| Connect tandem pump tester -VAS 5187- with banjo bolt -VAS 5187/1A- as shown in the illustration. |

| –

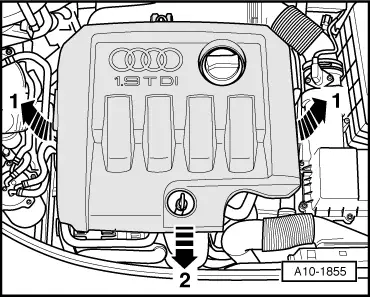

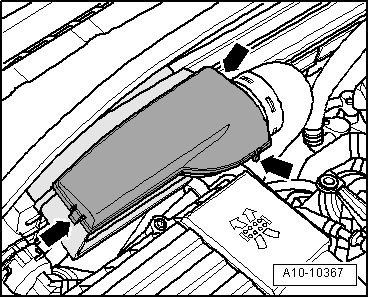

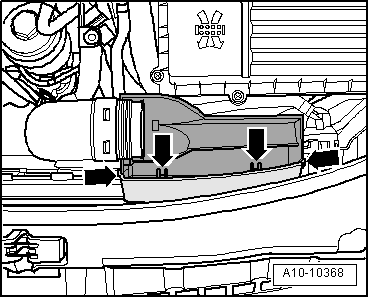

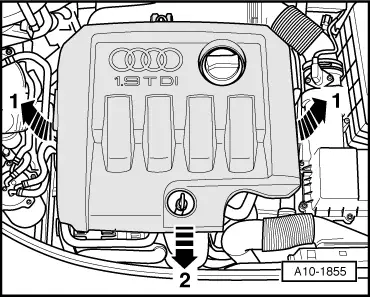

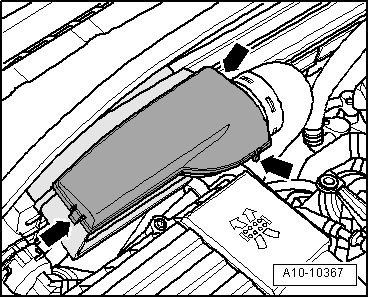

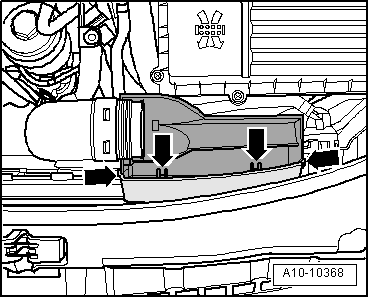

| Re-install air cleaner housing with air mass meter. |

| –

| Increase engine speed to 4000 rpm. |

| –

| Read off pressure indicated on pressure gauge: |

| l

| Specification: at least 7.5 bar |

| If specification is not obtained: |

| –

| Clamp off return hose between fuel filter and tandem pump using hose clamp. |

| –

| Increase engine speed to 4000 rpm. |

| –

| Read off pressure indicated on pressure gauge: |

| l

| Specification: at least 7.5 bar |

| If specification is now obtained: pressure is being lost at unit injectors. |

| –

| Renew O-rings at unit injectors. |

| If specification is not obtained: |

Note | After removing pressure tester, tighten screw plug to 25 Nm. Renew seal. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note