| –

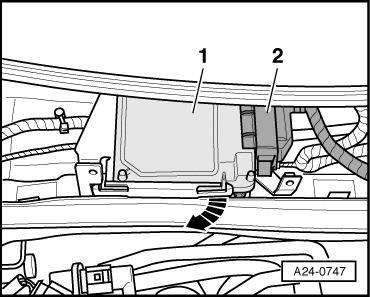

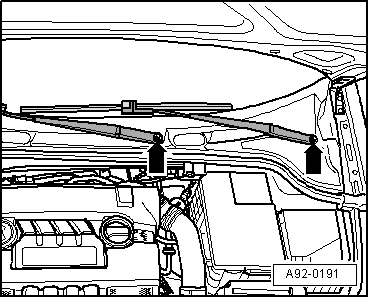

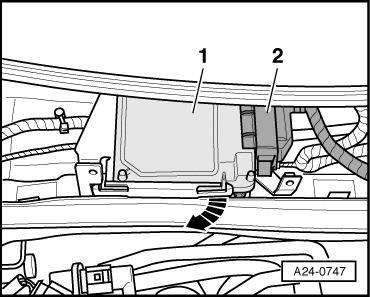

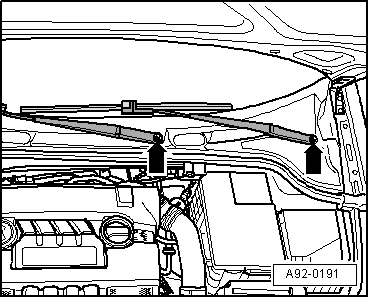

| Release and unplug front multi-pin connector -2- on engine control unit. |

| –

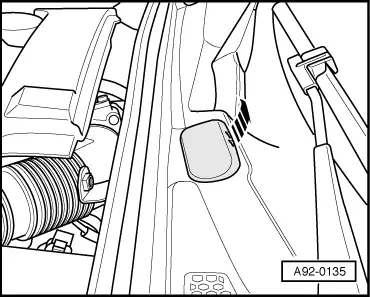

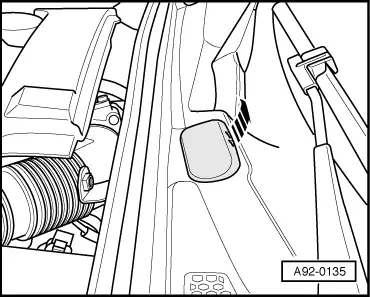

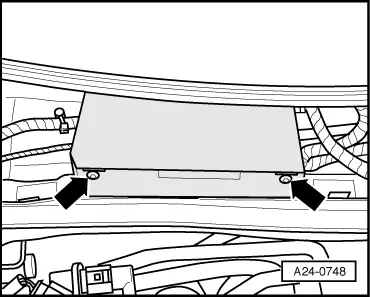

| Release retaining clip -arrow-. |

| –

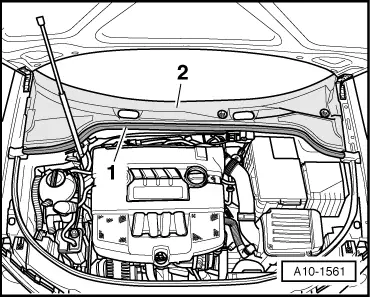

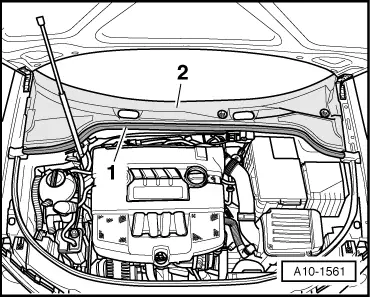

| Pull engine control unit -1- out of bracket. |

| –

| Release and unplug rear multi-pin connector on engine control unit. |

Note | When the connectors are disconnected from the engine control unit, the learnt values are erased but the contents of the fault memory remain intact. |

| Installation is carried out in the reverse order; note the following: |

| –

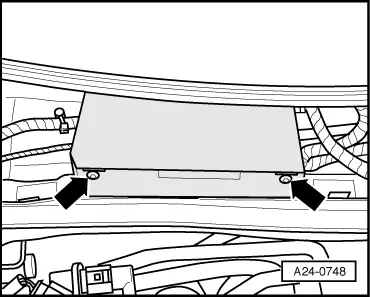

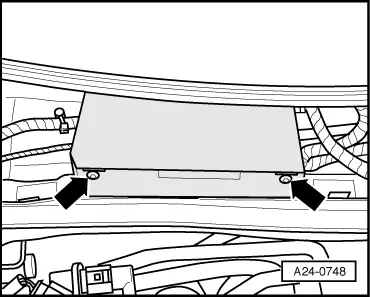

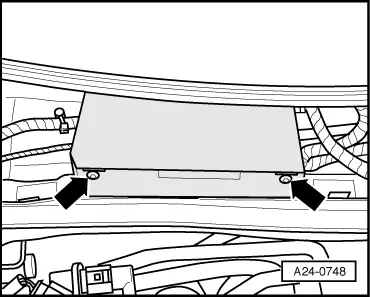

| Reinstall the engine control unit into the protective housing. |

| –

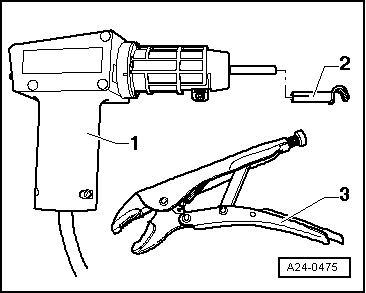

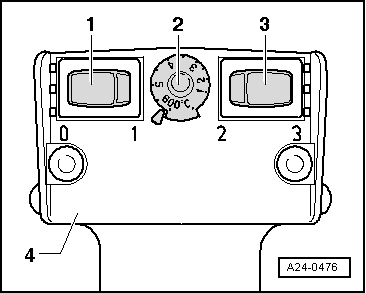

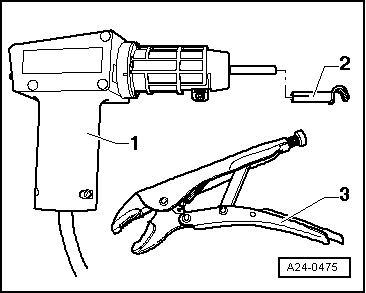

| Clean threaded holes for shear bolts to remove any residue from locking fluid. This can be done using a thread tap. |

| After installing a new engine control unit, the following operations must be performed: |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note