| –

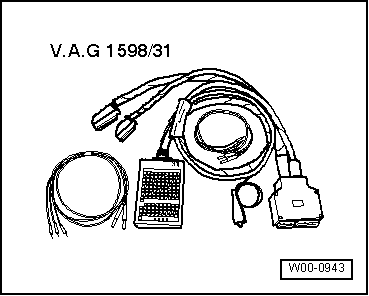

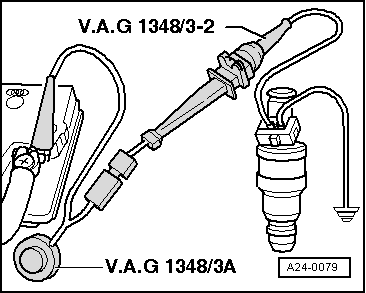

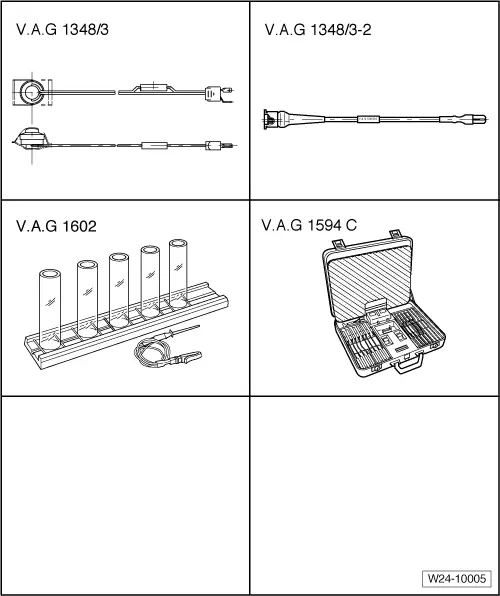

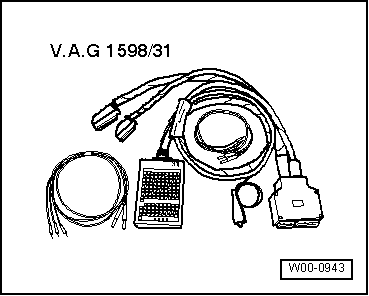

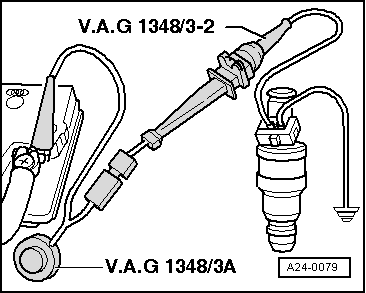

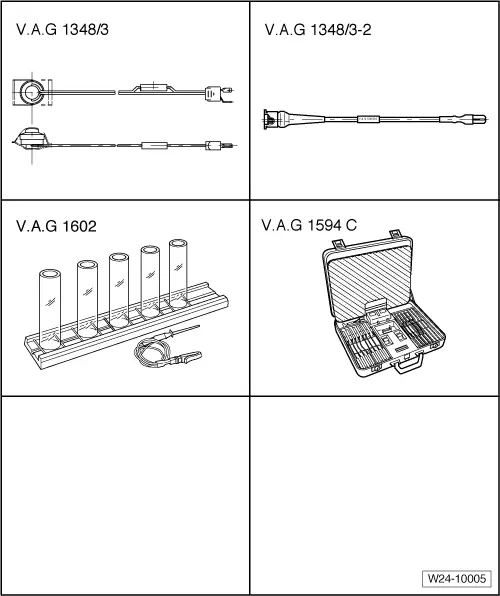

| Connect one of the injector contacts to engine earth using test lead and crocodile clip from auxiliary measuring set -V.A.G 1594C-. |

| –

| Connect second injector contact to positive using remote control for V.A.G 1348 -V.A.G 1348/3A-, adapter lead -V.A.G 1348/3-2- and test lead. |

| t

| The fuel pump should run. |

| –

| Operate remote control for V.A.G 1348 -V.A.G 1348/3A- for 30 seconds. |

| –

| Perform measurements on all injectors. |

| –

| Once all four injectors have been actuated, place measuring glasses on a level surface. |

| t

| Specification: 85...105 ml for each injector |

| –

| When checking the injection quantity, also check the spray pattern. The spray pattern should be the same for all injectors. |

| –

| If the measured value for one or more of the injectors is outside the tolerance range, switch off the fuel pump (switch off ignition) and renew the defective injector. |

| –

| Install injectors together with fuel rail → Chapter. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note