A3 Mk2

|

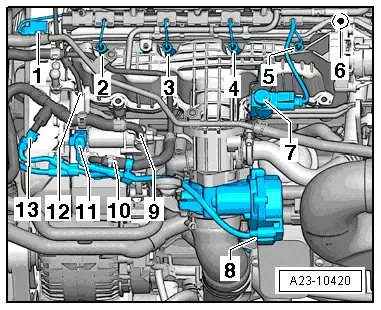

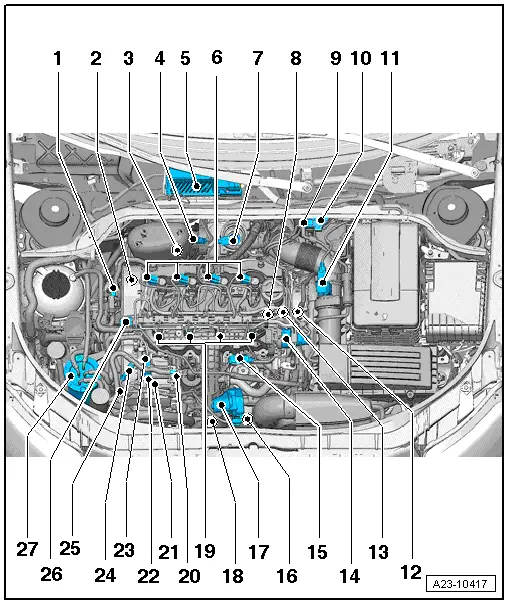

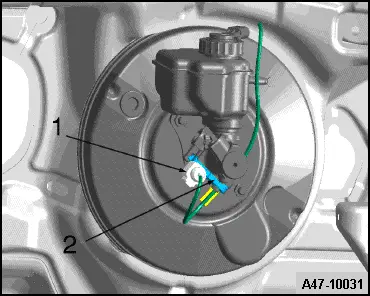

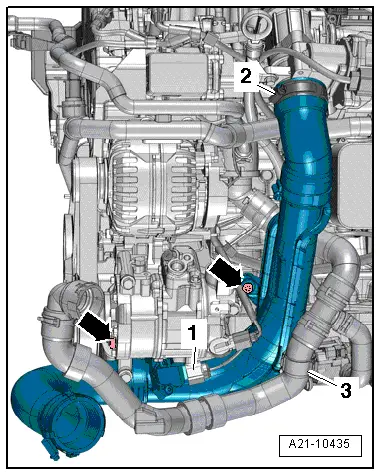

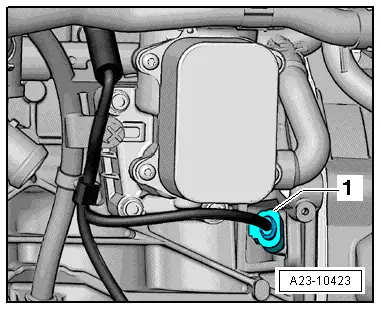

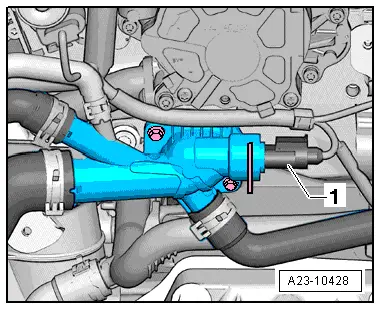

| 1 - | Pressure differential sender -G505- |

| q | Fitting location → Fig. |

| q | Adaption must be performed after renewing this component |

| q | Removing and installing → Chapter |

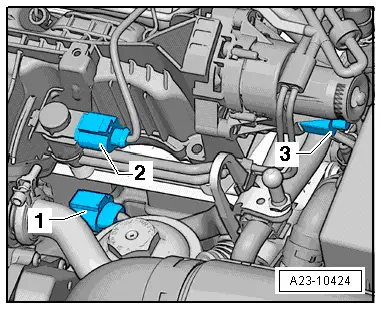

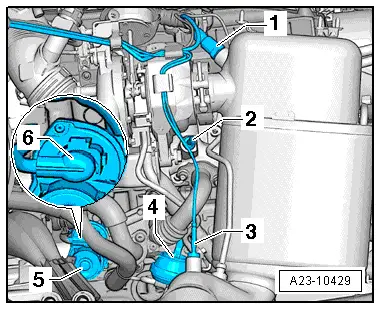

| 2 - | Hall sender -G40- |

| q | Fitting location → Fig. |

| q | Removing and installing → Chapter |

| q | 10 Nm |

| 3 - | Exhaust gas temperature sender 3 -G495- |

| q | Fitting location → Fig. |

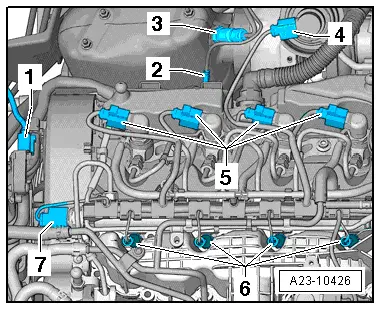

| 4 - | Lambda probe -G39- with Lambda probe heater -Z19- |

| q | Fitting location → Fig. |

| q | Removing and installing → Chapter |

| q | 50 Nm |

| 5 - | Engine control unit -J623- |

| q | Fitting location → Fig. |

| q | Removing and installing → Chapter |

| 6 - | Injectors |

| q | Fitting location → Fig. |

| q | Removing and installing → Chapter |

| 7 - | Position sender for charge pressure positioner -G581- |

| q | Fitting location → Fig. |

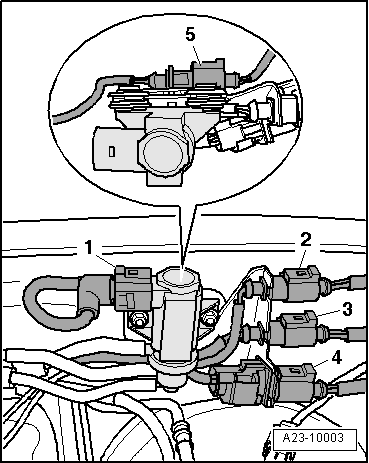

| 8 - | Fuel pressure regulating valve -N276- |

| q | Fitting location → Fig. |

| q | Removing and installing → Chapter |

| q | 80 Nm |

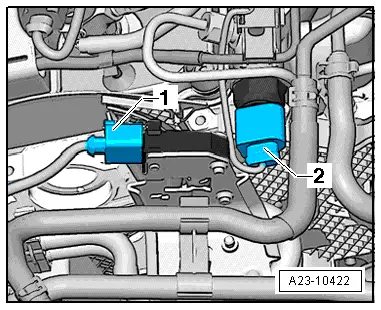

| 9 - | Charge pressure control solenoid valve -N75- |

| q | Fitting location → Fig. |

| q | Electrical connector for exhaust gas temperature sender 3 -G495- |

| 10 - | Electrical connector |

| q | For exhaust gas temperature sender 4 -G648- |

| q | For exhaust gas temperature sender 1 -G235- |

| q | For Lambda probe -G39- |

| q | Fitting location → Fig. |

| 11 - | Air mass meter -G70- |

| q | Removing and installing → Chapter |

| 12 - | Coolant temperature sender -G62- |

| q | Fitting location → Fig. |

| q | Removing and installing → Rep. gr.19 |

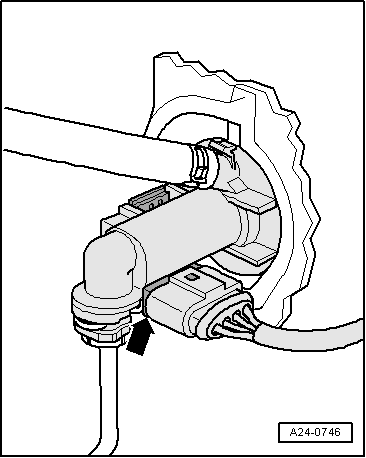

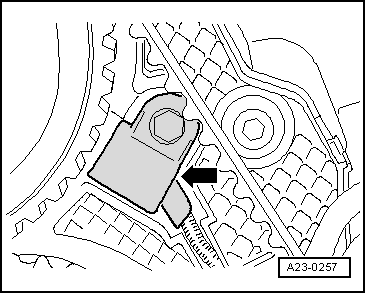

| 13 - | Engine speed sender -G28- |

| q | Fitting location → Fig. |

| q | 4.5 Nm |

| 14 - | Intake manifold flap motor -V157- |

| q | With intake manifold flap potentiometer -G336- |

| q | Fitting location → Fig. |

| 15 - | Exhaust gas recirculation cooler change-over valve -N345- |

| q | Fitting location → Fig. |

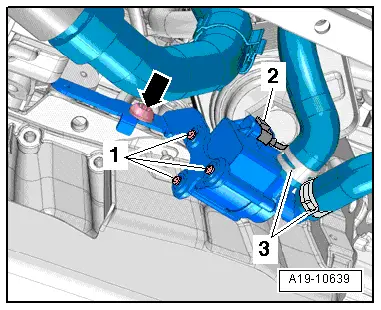

| 16 - | Pump for exhaust gas recirculation cooler -V400- |

| q | Fitting location → Fig. |

| 17 - | Throttle valve module -J338- |

| q | With throttle valve potentiometer -G69- |

| q | Fitting location → Fig. |

| q | Intake manifold with attached components - exploded view → Chapter |

| q | Removing and installing → Chapter |

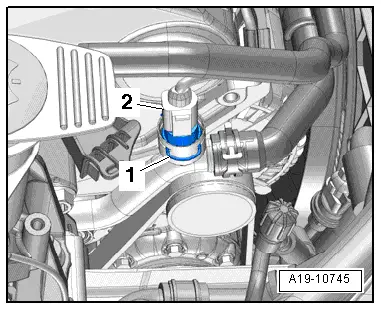

| 18 - | Charge pressure sender -G31- |

| q | Combined with intake air temperature sender -G42- |

| q | Fitting location → Fig. |

| q | Removing and installing → Rep. gr.21 |

| 19 - | Glow plugs |

| q | Fitting location → Fig. |

| q | Glow plug 1 -Q10- |

| q | Glow plug 2 -Q11- |

| q | Glow plug 3 -Q12- |

| q | Glow plug 4 -Q13- |

| q | Removing and installing → Chapter |

| 20 - | Fuel supply line connection from fuel filter |

| q | Fitting location → Fig. |

| 21 - | Fuel return line connection to fuel filter |

| q | Fitting location → Fig. |

| 22 - | High-pressure pump with fuel metering valve -N290- |

| q | Fitting location → Fig. |

| q | Do not open fuel metering valve -N290- |

| q | After renewing, first fuel filling MUST be performed (it is important not to allow pump to run while it is still empty) → Chapter |

| q | Removing and installing → Chapter |

| 23 - | Fuel supply line connection (high-pressure pipe) to fuel rail |

| q | Fitting location → Fig. |

| 24 - | Fuel temperature sender -G81- in fuel supply line |

| q | Fitting location → Fig. |

| 25 - | Radiator outlet coolant temperature sender -G83- |

| q | Fitting location → Fig. |

| q | Removing and installing → Rep. gr.19 |

| 26 - | Fuel pressure sender -G247- |

| q | Fitting location → Fig. |

| q | Removing and installing → Chapter |

| q | 100 Nm |

| 27 - | Fuel filter |

| q | Fuel filter - exploded view → Rep. gr.20 |

| q | Renewing fuel filter → Rep. gr.20 |

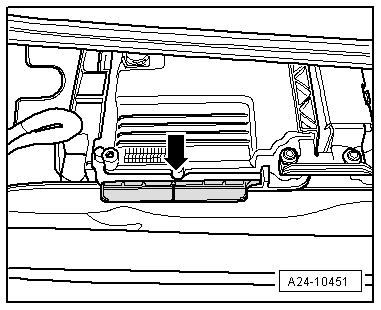

| A - | Low heat output relay -J359- and high heat output relay -J360- |

| q | Fitting location → Current flow diagrams, Electrical fault finding and Fitting locations |

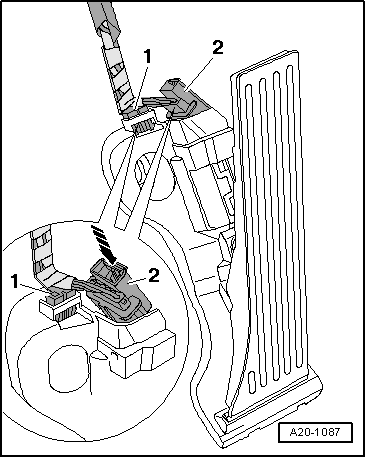

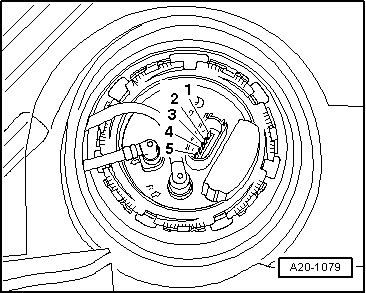

| B - | Brake light switch -F- and brake pedal switch -F47- |

| q | Fitting location → Fig. |

| q | In footwell on brake pedal |

| C - | Clutch position sender -G476- |

| q | Fitting location → Fig. |

| q | Only fitted on vehicles with manual gearbox |

| D - | Accelerator position sender -G79- and accelerator position sender 2 -G185- |

| q | Fitting location → Fig. |

| q | Removing and installing → Rep. gr.20 |

| E - | Exhaust gas recirculation valve -N18- with exhaust gas recirculation potentiometer -G212- |

| q | Fitting location → Fig. |

| F - | Exhaust gas temperature sender 1 -G235- |

| q | Fitting location → Fig. |

| q | Lambda probes and exhaust gas temperature sensors - exploded view → Chapter |

| q | Removing and installing → Rep. gr.26 |

| G - | Exhaust gas temperature sender 4 -G648- |

| q | Fitting location → Fig. |

| q | Lambda probes and exhaust gas temperature sensors - exploded view → Chapter |

| q | Removing and installing → Rep. gr.26 |

| H - | Particulate filter |

| q | Fitted on underbody |

| q | Combined with a catalytic converter |

| q | Adaption must be performed after renewing this component |

| q | Removing and installing → Rep. gr.26 |

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|