| –

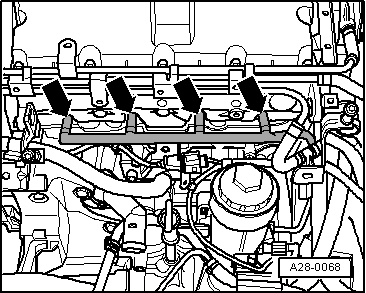

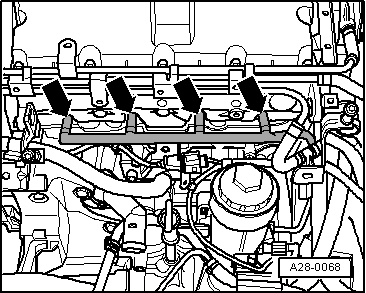

| Detach electrical connectors at glow plugs -arrows-. |

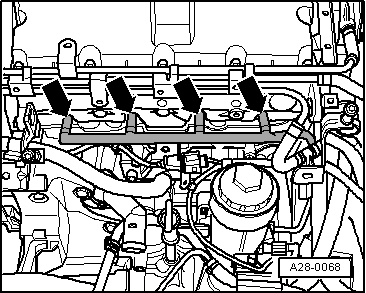

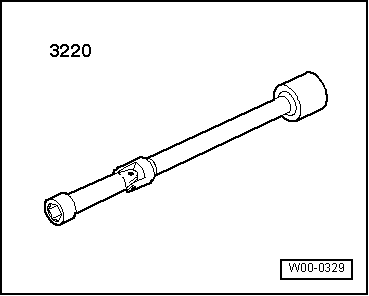

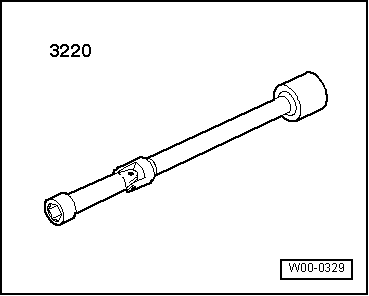

Caution | When loosening a ceramic glow plug, do not exceed the maximum release torque of 20 Nm. When loosening, always use U/J extension and socket, 10 mm -3220- and a torque wrench. |

|

| –

| Carefully slacken glow plug. Do not exceed the maximum release torque of 20 Nm. |

| If the glow plug cannot be unscrewed with the maximum permitted torque of 20 Nm: |

| –

| Apply a suitable release agent (commercially available) and then try to unscrew the glow plug again. |

Note | If it is still not possible to slacken the glow plug with the maximum release torque of 20 Nm after applying the release agent, remove the cylinder head and then unscrew the glow plug. |

| –

| Fit hose -N 020 150 05- (approx. 250 mm long) onto glow plug and unscrew glow plug, taking care to keep it straight. |

| –

| Carefully pull ceramic glow plug out from above using hose. Take care to prevent glow plug from contacting other parts. |

Caution | t

| IMPORTANT: always observe the precautions listed above. |

| t

| The threads in the cylinder head and on the ceramic glow plugs must be dry, and free of oil and grease. |

|

| –

| Clean combustion deposits out of glow plug openings in cylinder head before installing glow plugs. |

| –

| Screw in ceramic glow plugs finger-tight. |

Caution | It is most important to keep to the specified tightening torque for the glow plugs: 12 Nm (threads dry, and free of oil and grease). The heater pins of the glow plugs can break if this torque setting is not observed, which would invariably cause engine damage. |

|

| Check function of ceramic glow plugs after installation and before starting engine for the first time. |

| –

| Connect multimeter (resistance test) to contact and body of glow plug. |

| l

| Specification: less than 1 Ω |

| If specification is exceeded (resistance more than 1 Ω): |

| –

| Renew ceramic glow plug. |

| –

| Re-attach electrical connectors, making sure that they are securely seated. |

| 1.

| Interrogate and erase fault memory of engine control unit. Do not start engine. |

| 2.

| Perform final control diagnosis. |

| 3.

| Interrogate fault memory of engine control unit once again. Do not start engine. |

Note | The engine must not be started if the fault memory has registered a fault relating to the ceramic glow plugs. |

| –

| Check electrical wiring and connectors, make sure connectors are securely seated. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note