| –

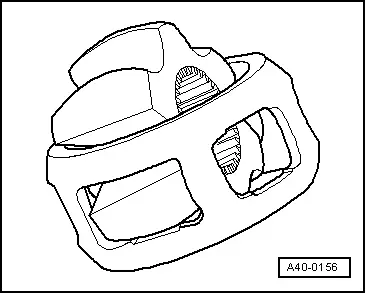

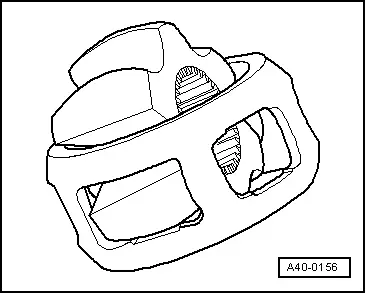

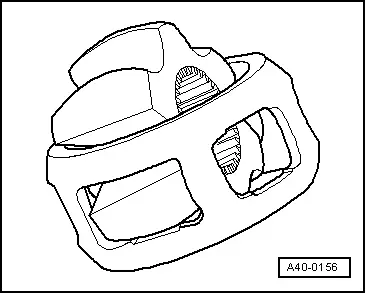

| Swivel one segment of the hub into one of the cage openings. |

Note | t

| The 6 balls in each joint belong to one tolerance group. Check stub axle, hub, cage and balls for pitting and signs of seizure. |

| t

| Excessive backlash in the joint will cause knocking or jolts under load change; in such cases the joint must be renewed. |

| t

| Polished areas and visible tracks in the ball races do not justify renewal of the joint. |

| Installation is performed in reverse sequence; note the following: |

| –

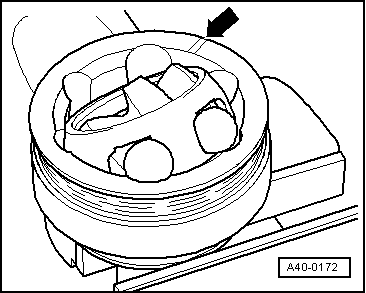

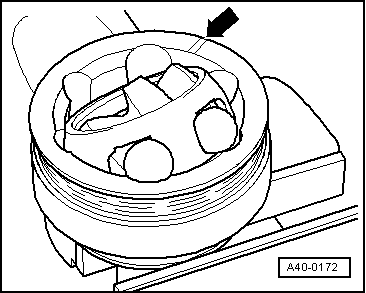

| Pack required amount of grease into joint body (check table). |

| t

| Grease quantity for outer joint (90 mm dia.) → Anchor |

| t

| Grease quantity for outer joint (98 mm dia.) → Anchor |

| –

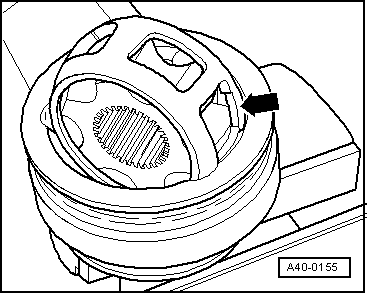

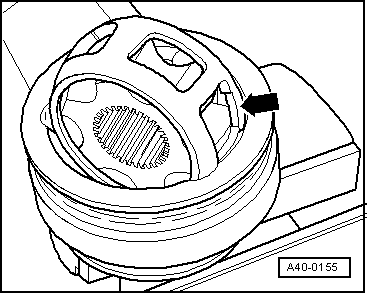

| Fit cage with hub into joint body. |

Note | Make sure cage is inserted in correct position (i.e. sides facing in same direction as original position). |

| –

| Press in balls one after the other from opposite sides, taking care to re-establish original position of hub relative to cage and joint body. |

| –

| Fit new circlip in shaft. |

| –

| Distribute remaining grease in boot. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note