| –

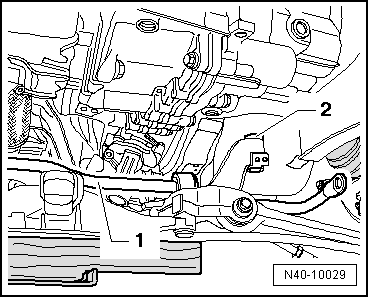

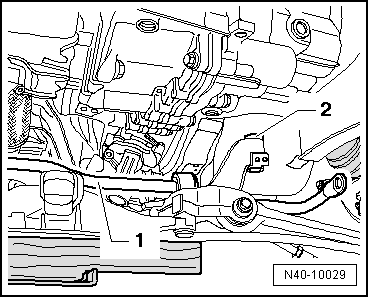

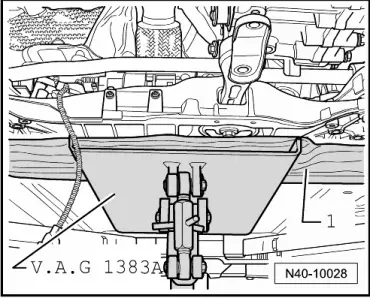

| Then remove anti-roll bar -1- from subframe and over suspension bracket -2- towards front of vehicle. |

| Installation is performed in reverse sequence; note the following: |

Note | t

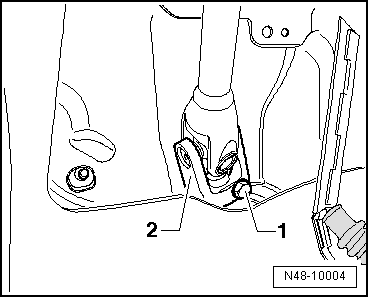

| Coat seal on steering box with suitable lubricant, e.g. soft soap, before installing steering box. |

| t

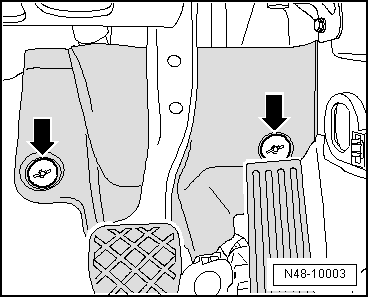

| After positioning steering box in relation to universal joint, ensure seal on steering box makes snug contact with base plate, without kinks, and properly seals off opening to footwell. Otherwise, this can result in water leaks and/or noise. |

| t

| Make sure sealing surfaces are clean. |

| –

| Check and adjust wheel alignment as required, see chart → Anchor. |

|

|

|

Note

Note