A3 Mk2

| Removing and installing swivel joint |

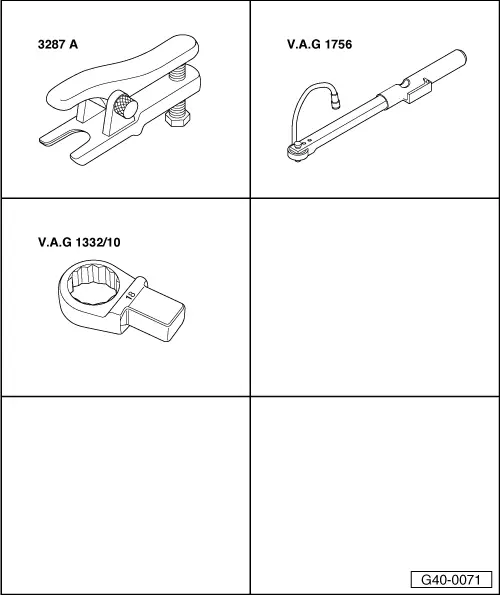

| Special tools and workshop equipment required |

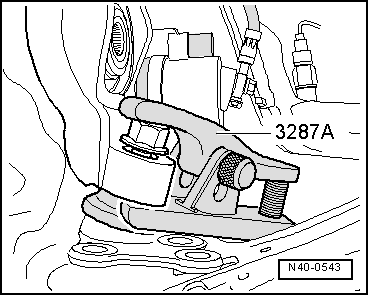

| t | Ball joint puller -3287 A- |

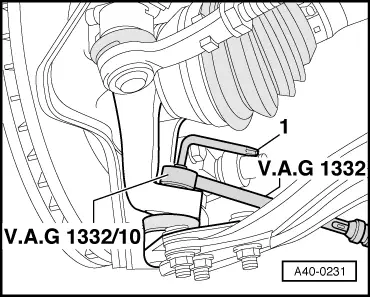

| t | Angle wrench -V.A.G 1756- |

| t | Ring spanner insert -V.A.G 1332/10- |

|

Note

Note

|

|

|

|

Note

Note

|

|

WARNING

WARNING