| –

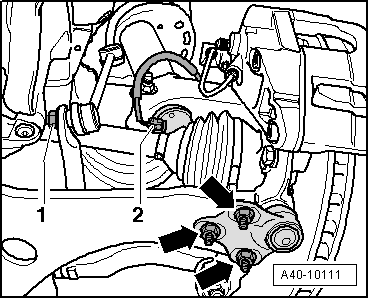

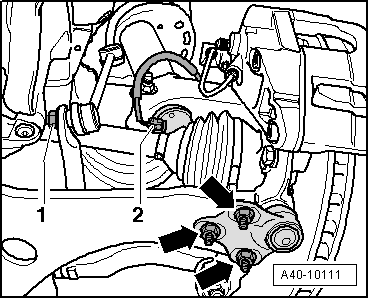

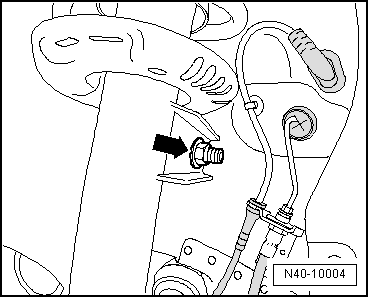

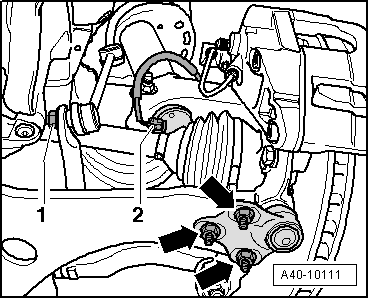

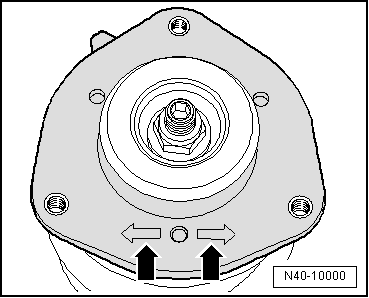

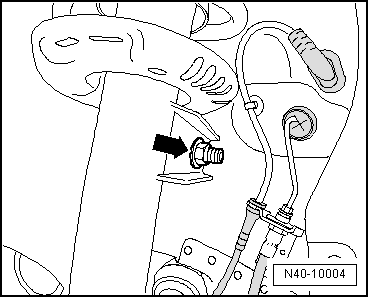

| On vehicles with electronic damping control (Audi magnetic ride), unplug connector -2-. |

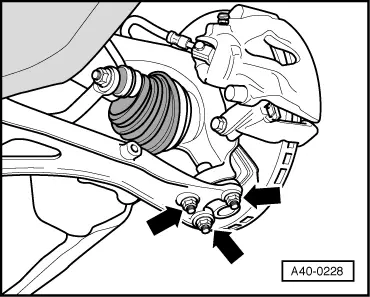

| -Arrows- can be disregarded. |

Note | Use both hands to remove the connector: open the catch with one hand whilst pressing off the connector with the other; do not use any tools. |

| –

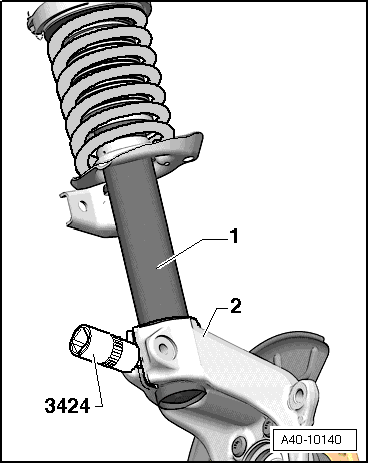

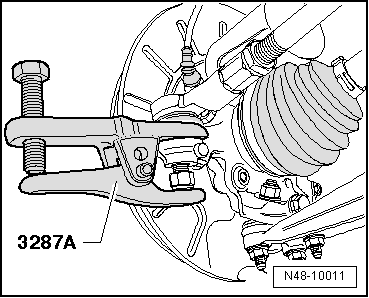

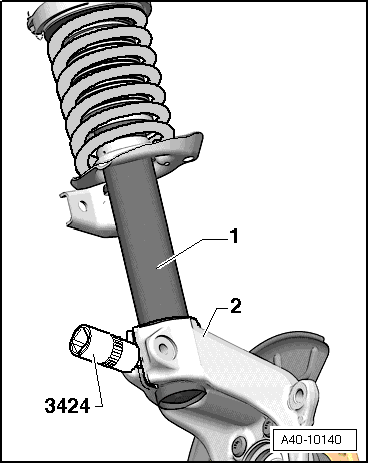

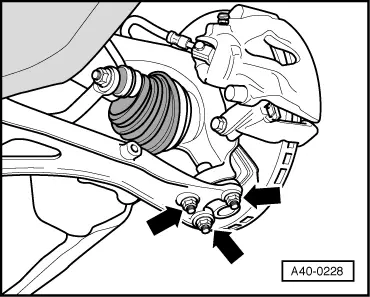

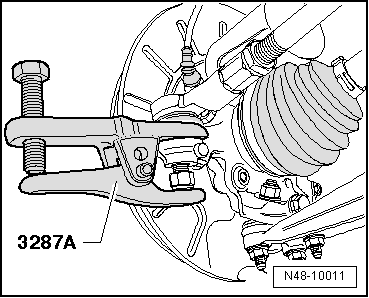

| Detach wishbone from swivel joint and pull wheel bearing housing off drive shaft splines. |

Note | t

| Do not let the drive shaft hang down under its own weight, as otherwise excessive bending could damage the inner CV joint. |

| t

| Tie up drive shaft to body with wire. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note