A3 Mk2

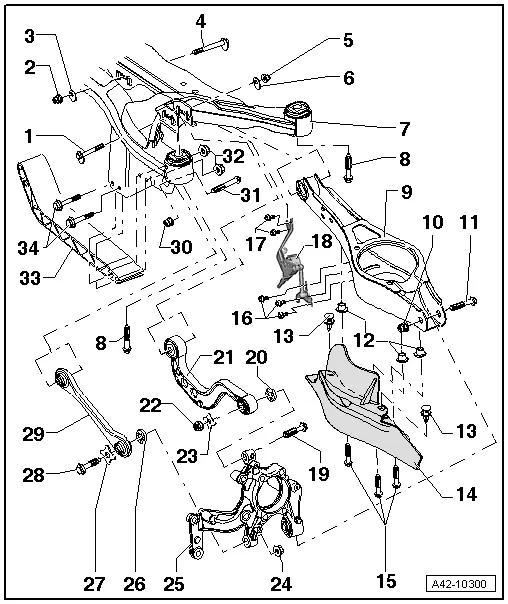

| Exploded view of subframe, lower transverse link, upper transverse link, track rod, vehicle level senders |

| 1 - | Eccentric bolt |

| q | After slackening off, perform wheel alignment → Chapter |

| q | Do not turn more than 90° in either direction (i.e. from minimum to maximum adjustment position) |

| 2 - | Self-locking nut |

| q | 95 Nm |

| q | Always renew if removed |

| q | Always tighten bolted joints with suspension in unladen position → Chapter |

| 3 - | Eccentric washer |

| q | With lug on inner bore |

| 4 - | Eccentric bolt |

| q | After slackening off, perform wheel alignment → Chapter |

| q | Do not turn more than 90° in either direction (i.e. from minimum to maximum adjustment position) |

| 5 - | Self-locking nut |

| q | 95 Nm |

| q | Always renew if removed |

| q | Always tighten bolted joints with suspension in unladen position → Chapter |

Note

Note| t | Set torque wrench V.A.G 1332 to 80 Nm to tighten nut. |

| t | This tightening torque only applies when using socket tool T10179. |

| 6 - | Eccentric washer |

| q | With lug on inner bore |

| 7 - | Subframe |

| q | Different versions: aluminium and steel |

| q | Only steel subframe available as replacement part. For correct version refer to → Electronic parts catalogue. If an aluminium subframe has to be renewed, a new brake line must also be installed → Rep. gr.47 and → Electronic parts catalogue. |

| q | Removing and installing → Chapter |

| q | Removing and installing subframe mountings → Chapter |

| 8 - | Bolt |

| q | 90 Nm + turn 90° further |

| q | Always renew if removed |

| 9 - | Lower transverse link |

| q | Removing and installing → Chapter |

| 10 - | Self-locking nut |

| q | 90 Nm + turn 90° further |

| q | Always renew if removed |

| q | Always tighten bolted joints with suspension in unladen position → Chapter |

| 11 - | Bolt |

| q | Always renew if removed |

| 12 - | Threaded rivet |

| q | M6 |

| 13 - | Spreader rivet |

| 14 - | Stone deflector |

| 15 - | Bolt |

| q | 8 Nm |

| 16 - | Bolt |

| q | 5 Nm |

| q | 2x on vehicles with electronic damping control (Audi magnetic ride) |

| q | 3x on vehicles with headlight range control |

| 17 - | Bolt |

| q | 5 Nm |

| 18 - | Rear left vehicle level sender -G76-, rear right vehicle level sender -G77- |

| q | Removing and installing → Chapter |

| q | Lever on sender must face outwards |

| 19 - | Bolt |

| q | 130 Nm + turn 90° further |

| q | Always renew if removed |

| q | Always tighten bolted joints with suspension in unladen position → Chapter |

| 20 - | Washer |

| q | Installed on vehicles with aluminium wheel bearing housing |

| q | For corrosion protection |

| q | Must always be installed |

| 21 - | Upper transverse link |

| q | Removing and installing → Chapter |

| 22 - | Nut |

| q | Always renew if removed |

| 23 - | Washer |

| 24 - | Nut |

| q | Always renew if removed |

| 25 - | Wheel bearing housing |

| q | Different versions: aluminium and steel |

| q | For correct version refer to → Electronic parts catalogue |

| q | Removing and installing → Chapter |

| 26 - | Washer |

| q | Installed on vehicles with aluminium wheel bearing housing |

| q | For corrosion protection |

| q | Must always be installed |

| 27 - | Washer |

| 28 - | Bolt |

| q | 130 Nm + turn 90° further |

| q | Always renew if removed |

| q | Always tighten bolted joints with suspension in unladen position → Chapter |

| 29 - | Track rod |

| q | Closed side faces direction of travel |

| 30 - | Nut |

| q | 90 Nm + turn 90° further |

| q | Always renew if removed |

| q | Always tighten bolted joints with suspension in unladen position → Chapter |

| 31 - | Bolt |

| q | Always renew if removed |

| 32 - | Nut |

| q | 50 Nm + turn 180° further |

| q | Always renew if removed |

| 33 - | Cross member |

| q | Not fitted on vehicles with steel subframe |

| q | For correct version refer to → Electronic parts catalogue |

| 34 - | Bolt |

| q | Always renew if removed |