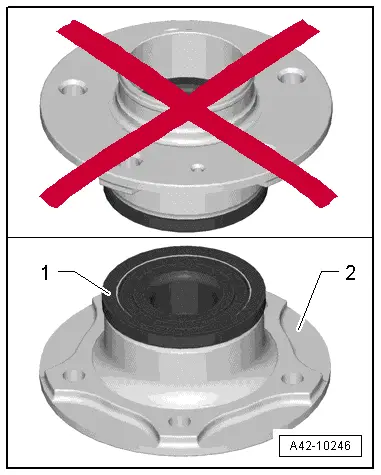

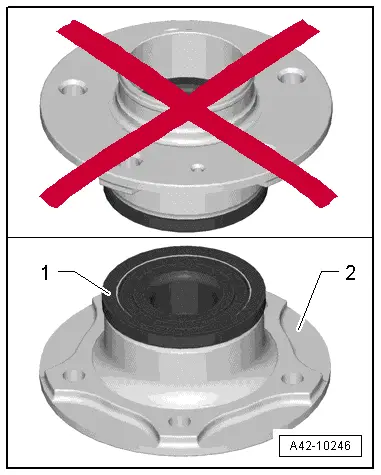

| The wheel bearing -1- must always be pointing upwards. |

| –

| Always put down the wheel bearing unit with the wheel hub -2- facing downwards. |

| Installation is performed in reverse sequence; note the following: |

| –

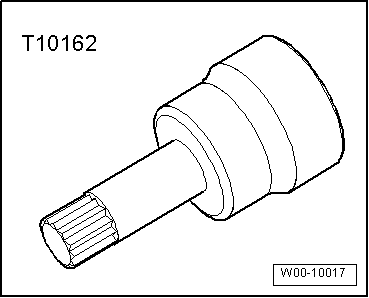

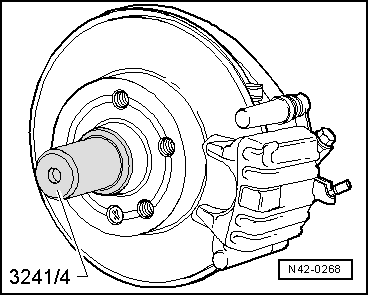

| Carefully slide wheel hub/wheel bearing unit onto stub axle. |

| Take care to keep wheel hub/wheel bearing unit straight. |

| –

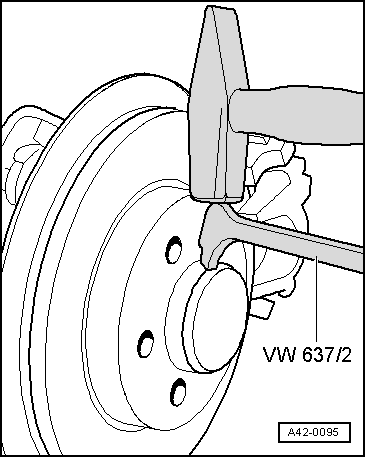

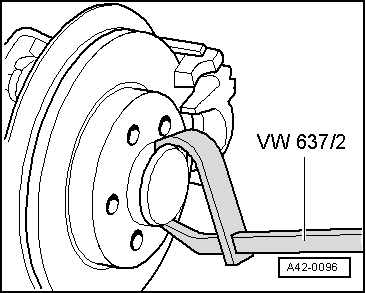

| Fit new multi-point socket head bolt and tighten bolt → Item. |

Note | t

| First tighten bolt with torque wrench to specified tightening torque. |

| t

| Use fixed wrench to turn bolt further through specified angle. |

|

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution