| –

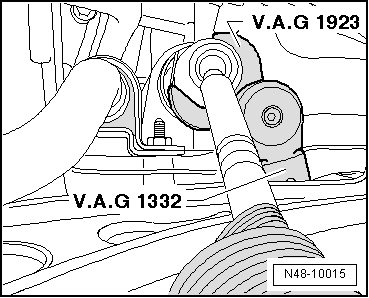

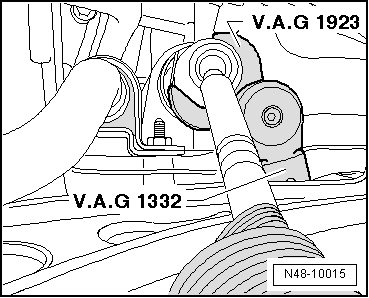

| Unscrew track rod from steering rack using open end spanner attachment (38 mm) -V.A.G 1923-. |

Note | t

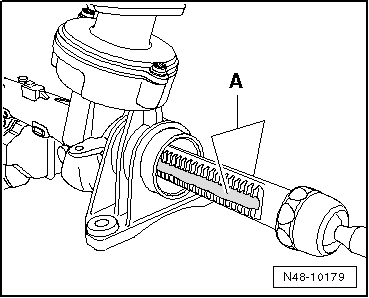

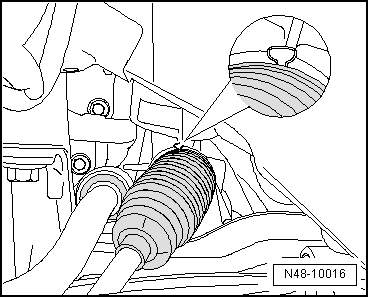

| Renew complete steering box if there are signs of corrosion, damage, wear or dirt on the steering rack. |

| t

| The complete steering box must also be renewed if there is no visible lubricating film on the steering rack. |

| The steering rack must be lubricated with grease supplied in the repair kit before installing. |

Caution | Do NOT use any other type of grease. |

|

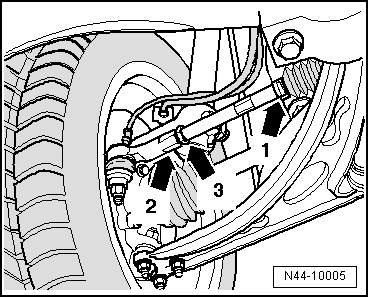

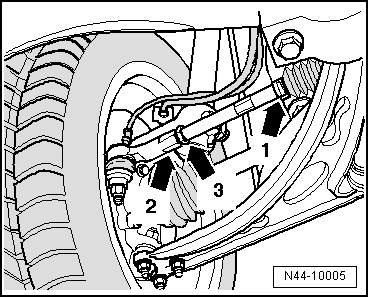

| For this procedure turn steering to full lock in both directions. |

| A removed steering box is shown for ease of illustration. |

|

|

|

Note

Note

Caution

Caution