A4 Cabriolet Mk2

| Renewing gearbox cover (with gearbox installed) |

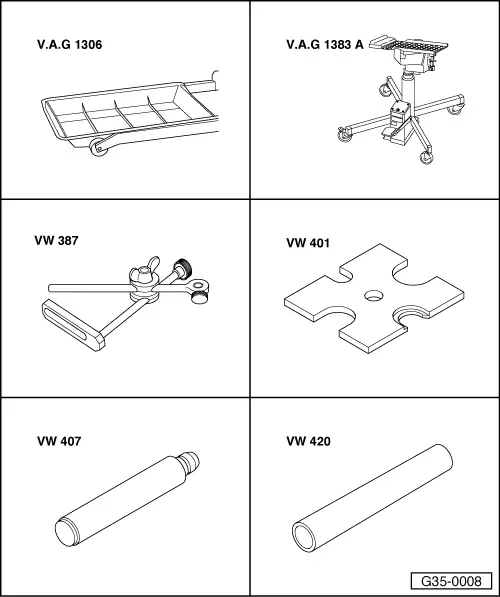

| Special tools and workshop equipment required |

| t | Drip tray -V.A.G 1306- or drip tray for workshop hoist-VAS 6208- |

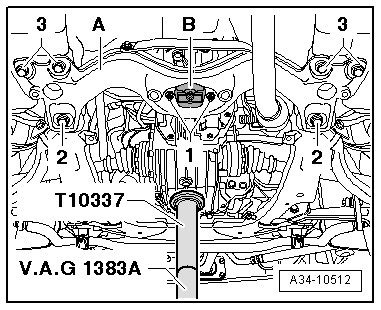

| t | Engine and gearbox jack -V.A.G 1383 A- |

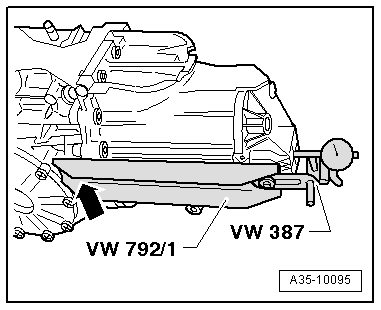

| t | Universal dial gauge bracket -VW 387- |

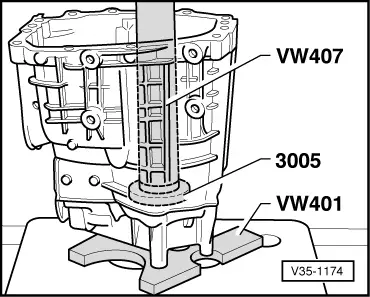

| t | Thrust plate -VW 401- |

| t | Press tool -VW 407- |

| t | Tube -VW 420- |

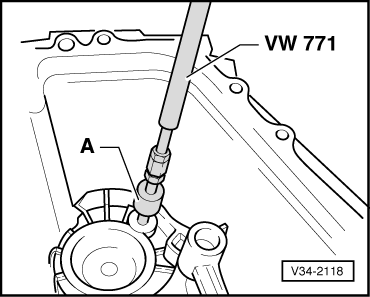

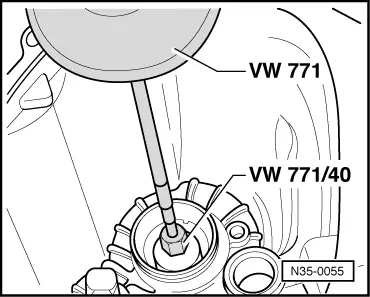

| t | Multi-purpose tool -VW 771- |

| t | Assembly device -VW 792- |

| t | Thrust plate -3005- |

| t | Multi-point bit -3357- |

| t | -1-Internal puller -Kukko 21/1- |

| t | Dial gauge |

| t | Dial gauge extension |

| t | Depth gauge (accurate to within 5/100 mm or less) |

| t | Sealants -AMV 188 001 02- |

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

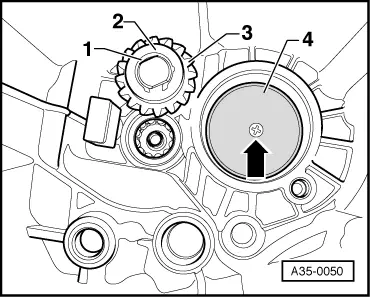

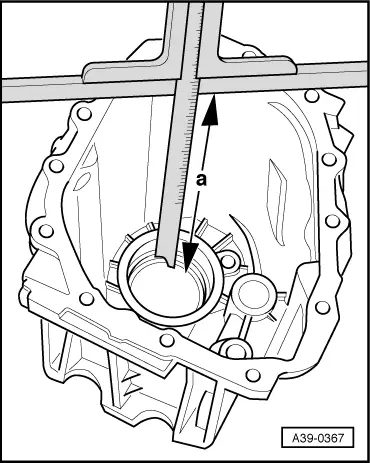

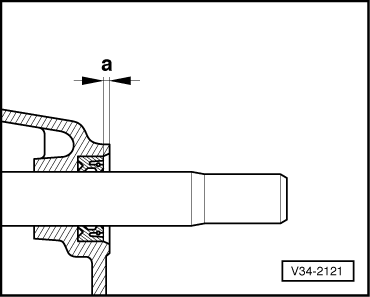

| Depth “a” (old gearbox cover) | 257.40 mm | |

| Depth “a” (new gearbox cover) | 257.56 mm | |

| = | Difference | 0.16 mm |

|

| Previous shim “S4” | 0.69 mm | |

| + | Difference | 0.16 mm |

| = | New shim “S4” | 0.85 mm |

|

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

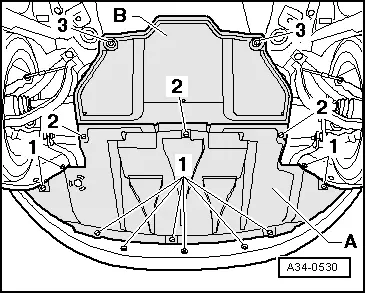

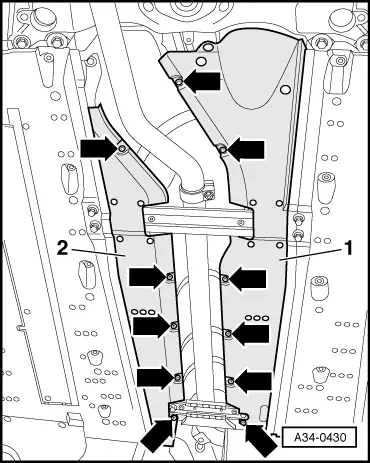

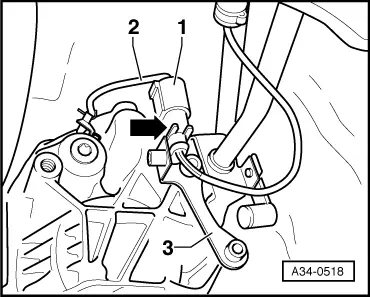

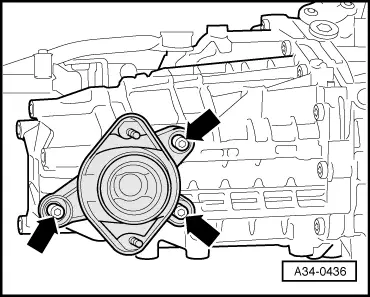

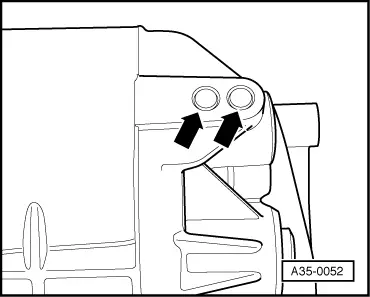

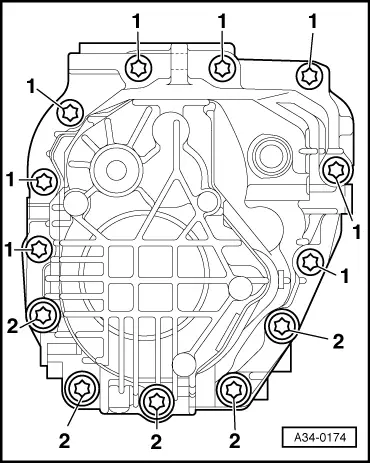

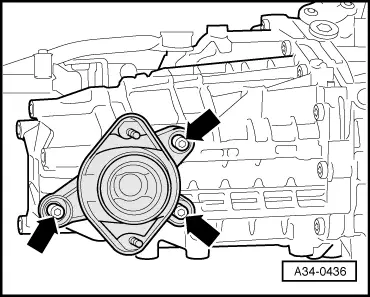

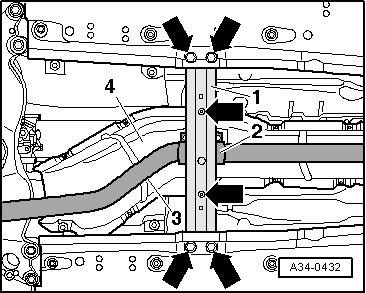

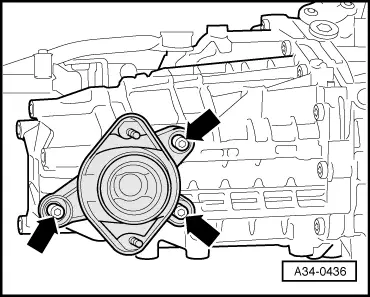

| Bolts -arrows- | 23 Nm |

|

|

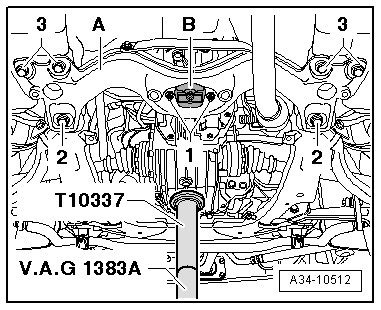

| Component | Nm | |||||

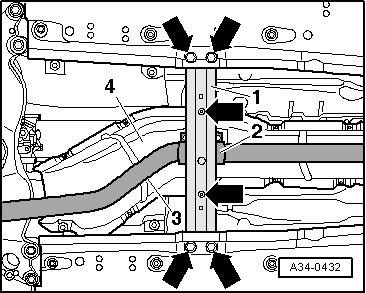

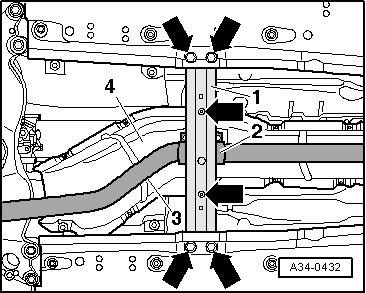

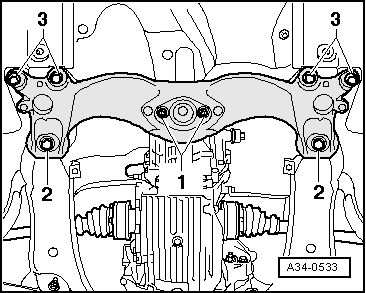

| -1- Tunnel cross member to gearbox mounting | 23 | |||||

| -2- Tunnel cross member to body 1) | 110 Nm + 90° 2) | |||||

| -3- Tunnel cross member to body 1) | M10 | 55 | ||||

| ||||||

| Component | Nm | |||

| Oil drain plug | 25 | |||

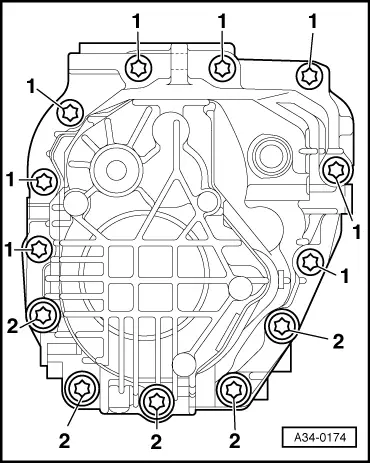

| Gearbox cover to gearbox housing | 22 | |||

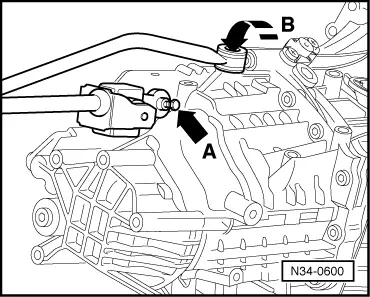

| Selector rod/selector joint to gearbox 1) | 23 | |||

| Push rod to gearbox | 40 | |||

| Tunnel cross piece (front) to body | 55 | |||

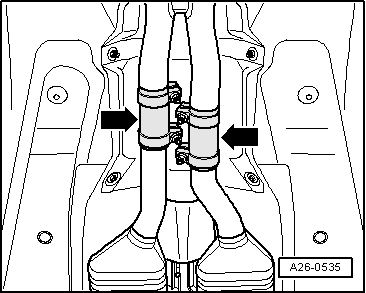

| Clamp for exhaust pipe | 40 | |||

| ||||

WARNING

WARNING